Novel electric resistance welding integral machine

A technology of resistance welding and all-in-one machine, which is applied in the direction of resistance welding equipment, welding power supply, welding equipment, etc., and can solve the problems of low production efficiency, single function of resistance welding equipment, time-consuming and labor-consuming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

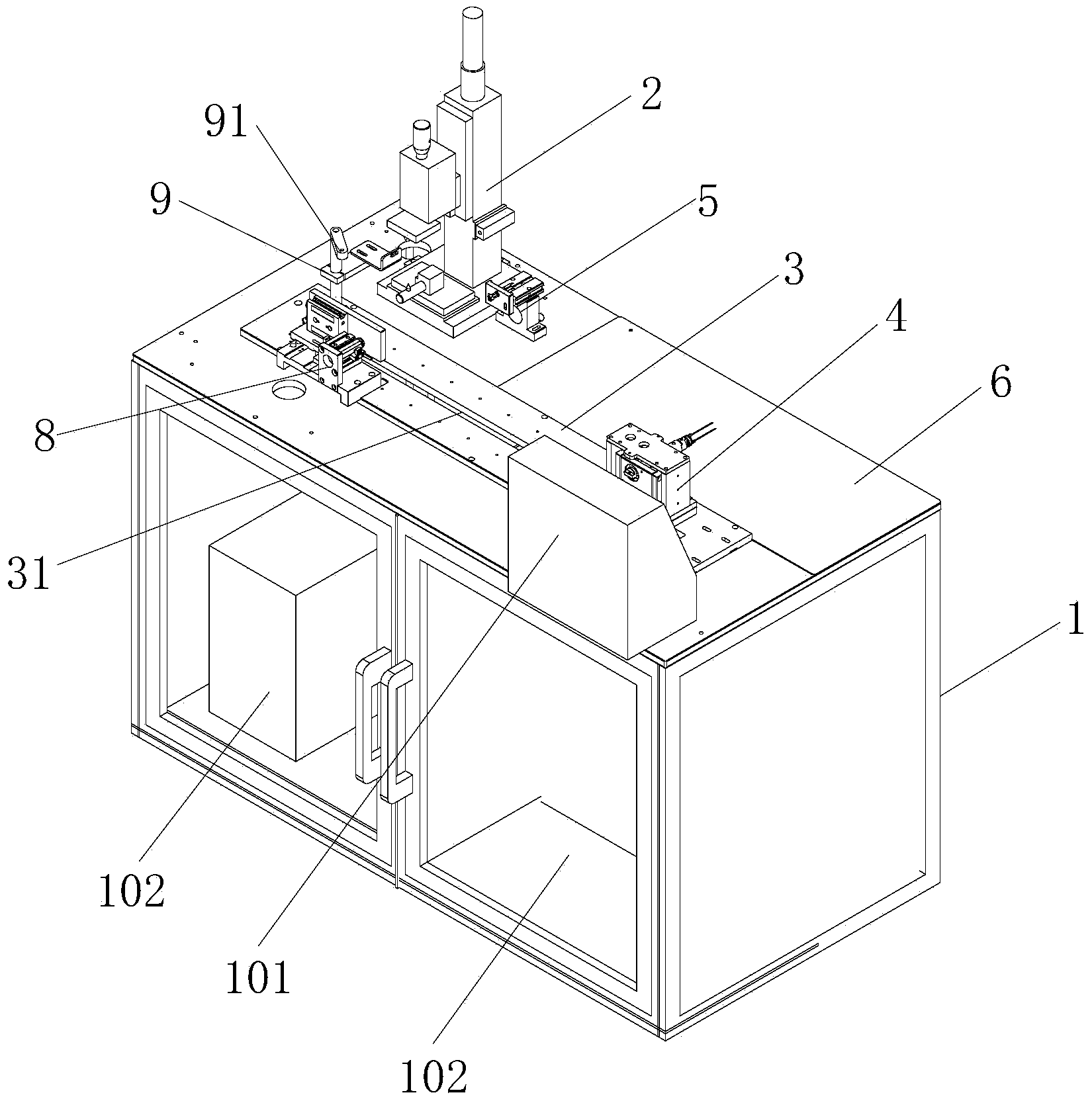

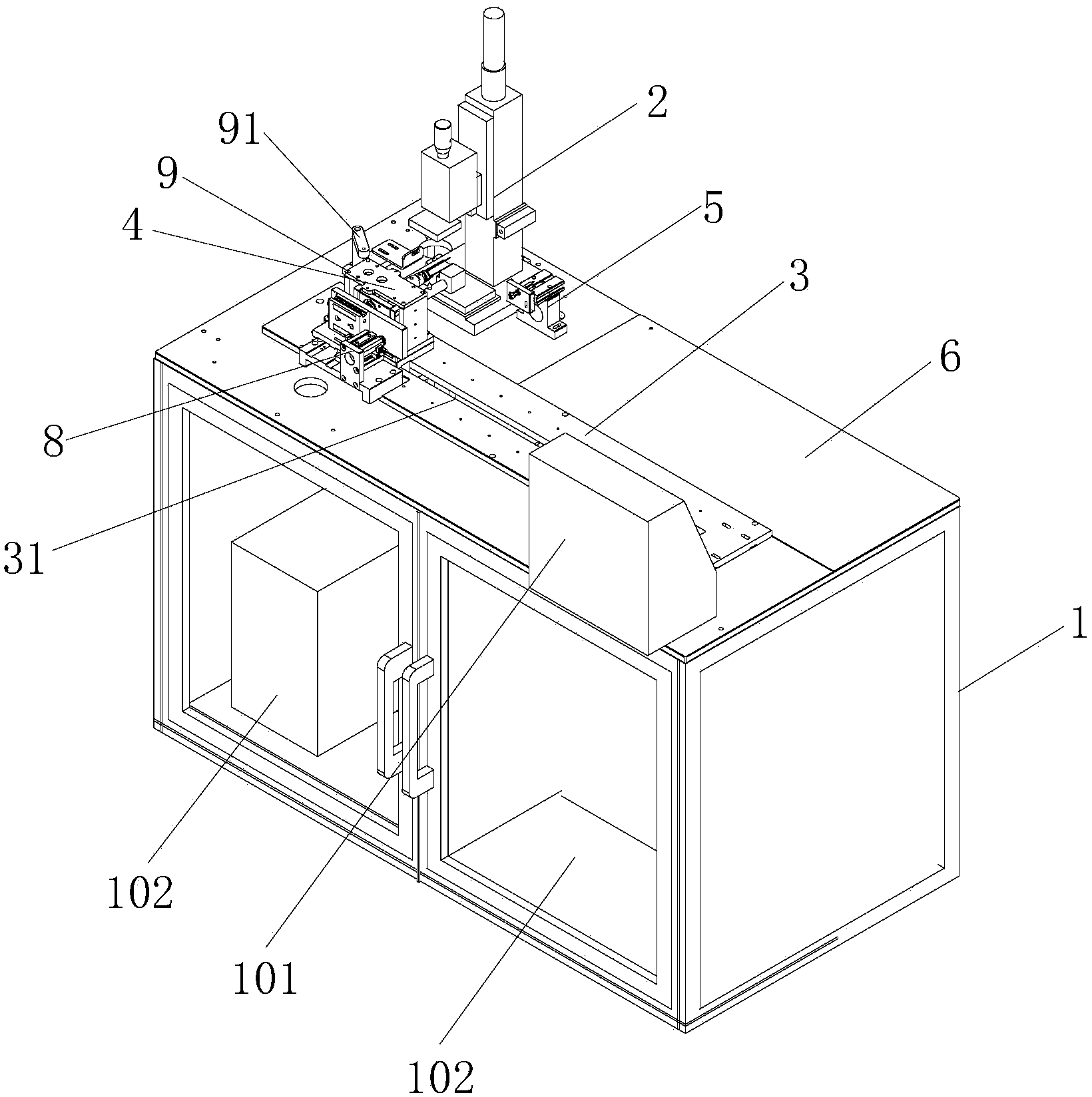

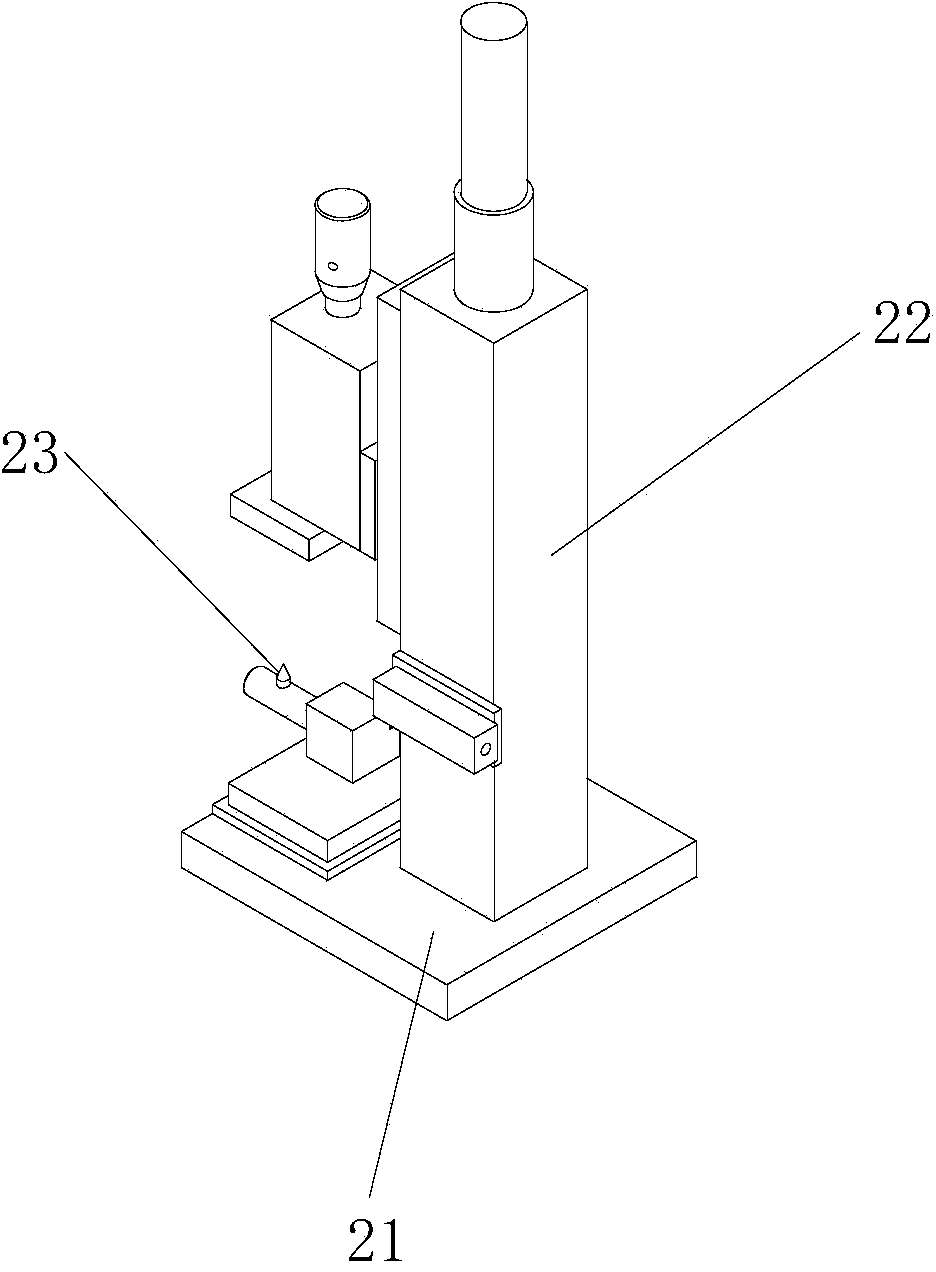

[0033] Such as figure 1 , figure 2 As shown, a new integrated resistance welding machine includes: machine 1; resistance welding equipment 2, which is arranged on one end of the machine 1, and is used to complete the welding work of products; a feeding mechanism, which is arranged on the machine 1, includes The traverse assembly 3 and the carrying device 4 which is connected to it in motion, the traverse assembly 3 includes a feeding end and a welding end, the resistance welding equipment 2 is located on one side of the welding end of the traverse assembly 3, and the carrying device 4 moves the product to be welded along the The component 3 is transported to the welding end and waits for welding by the resistance welding equipment 2; the detection mechanism 5 is set on the detection station on the machine 1, located on the side of the resistance welding equipment 2, and is used to detect the qualified rate of the welded products; the control device (not shown in the figure),...

Embodiment 2

[0040] The rest is the same as the above-mentioned embodiment, the difference is that the new all-in-one resistance welding machine also includes a rotating mechanism 8 for driving the rotation of the carrying jig 4, such as Figure 8 As shown, the rotating mechanism includes a base 81 and a rotating assembly arranged on the base 81, the rotating assembly includes a fixed plate 82 and a rotating cylinder 83 arranged on the fixing plate 82, and the rotating assembly is slidably connected to the base 81 through a sliding assembly; the rotating cylinder 83 The rotating shaft 84 is mated and connected to the end of the carrying jig 4 .

[0041] The slide assembly includes a moving cylinder 85, a slide block and a slide rail connected to the slide block. The slide rail is arranged on the base 81, the slide block is connected to the rotating mechanism, and the moving cylinder 85 drives the rotating mechanism to move back and forth along the slide rail. When the carrying device 4 mov...

Embodiment 3

[0044] The rest are the same as the above-mentioned embodiment, the difference is that, as figure 1 , figure 2 As shown, the new all-in-one resistance welding machine also includes a press-down mechanism 9 arranged on one side of the carrying device 4. The press-down mechanism 9 includes a press-down cylinder and a press plate 91 connected to the press-down cylinder. The end of the press plate 91 is provided with a downward convex out of the lower pressure part. The top plate 46 defines a through hole 461 , and the positions of the pressing portion, the through hole 461 and the sliding plate 44 correspond up and down.

[0045] The working principle of this embodiment is introduced below: during the welding process, when the upper and lower positions of the terminal 7 need to be adjusted, the pressing mechanism 9 can be started to work. The downward pressure cylinder drives the pressure plate 91 to move downward. The downward pressure part passes through the through hole 461...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com