Belt-turning mechanism

A technology for turning belts and sewing machines, which is applied in the direction of cloth feeding mechanism, mechanical cleaning, sewing machine components, etc., can solve the problems of time-consuming, laborious, low production efficiency, etc., and achieve the effect of improving production efficiency, reliable performance and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

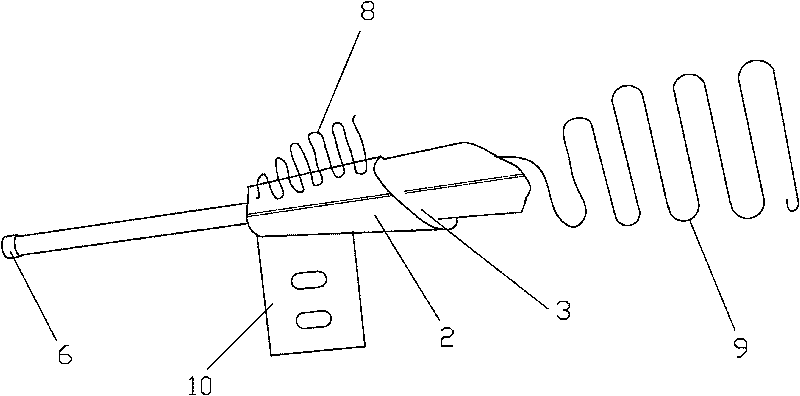

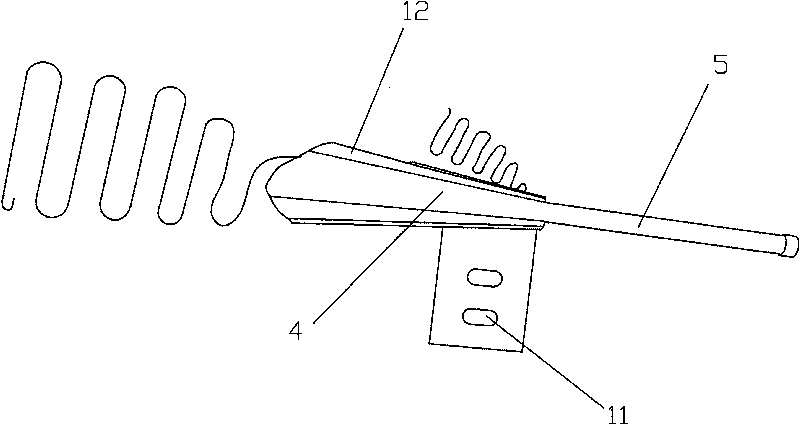

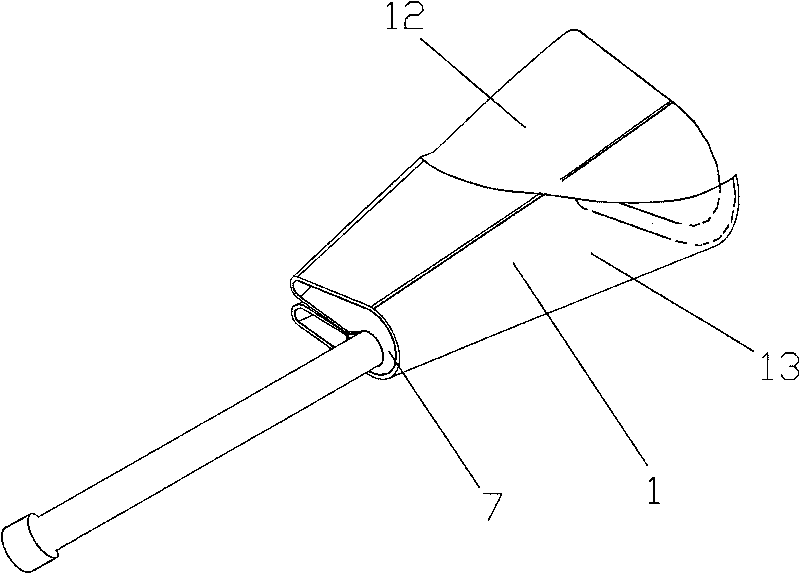

[0020] refer to Figure 1-3 : A kind of belt-turning mechanism, comprising the folding tube 1 that the tube body gradually draws in from the rear end to the front end, one side of the folding tube is sunken inward, and an outer wrapping cloth is formed between its inner edge and the other side 2 of the folding tube. The first channel 3 through which the bar is bent, and its outer edge forms a second channel 4 for pulling back the turning belt. The front end of the second channel 4 is connected with a hollow liner 5 communicating with it. The opening at the front end constitutes an inlet for the front end of the turning belt to extend into and pull back. There is a gap 7 for the outer cloth strip to pass between the outer edge of the liner 5 and the front outlet of the first passage 3. The upper end of the folding tube is The first serpentine frame 8 for pulling the inner lining elastic band is connected, the rear end of the folding cylinder is connected with the second serpent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com