Plank slotting machine

A slotting machine and wood board technology, applied in the field of wood board processing, can solve problems such as low work efficiency, achieve the effects of reducing labor intensity, improving work efficiency, and reducing potential safety hazards

Pending Publication Date: 2018-10-26

重庆哲骁装饰工程有限公司

View PDF0 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to provide a wood slotting machine to solve the problem of low work efficiency due to the need to manually turn over the wood when slotting

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0016] The present invention will be described in further detail below by means of specific embodiments:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

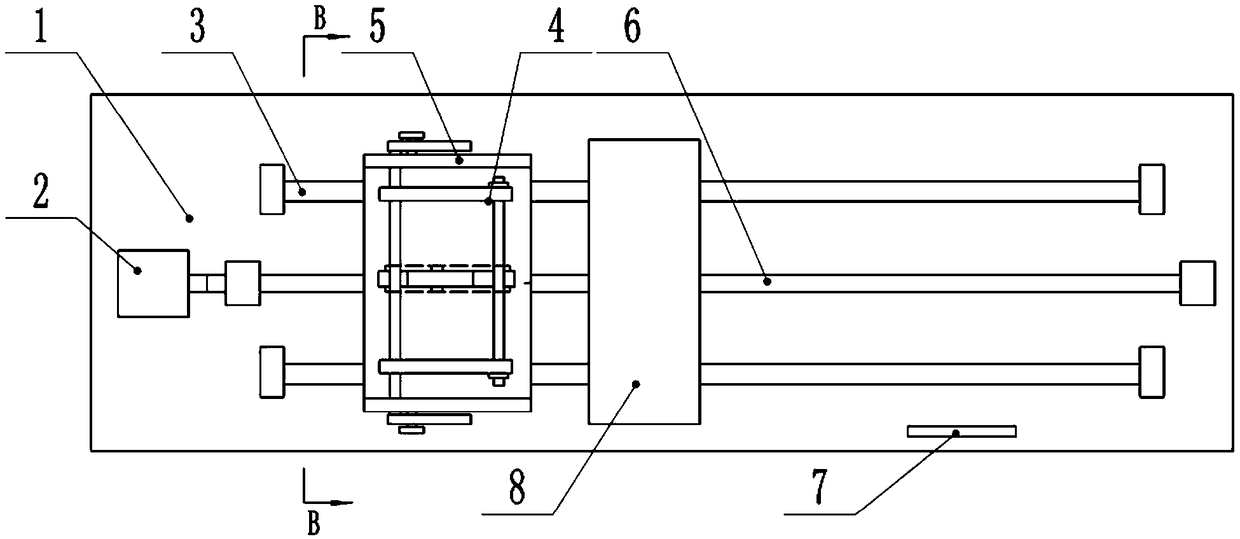

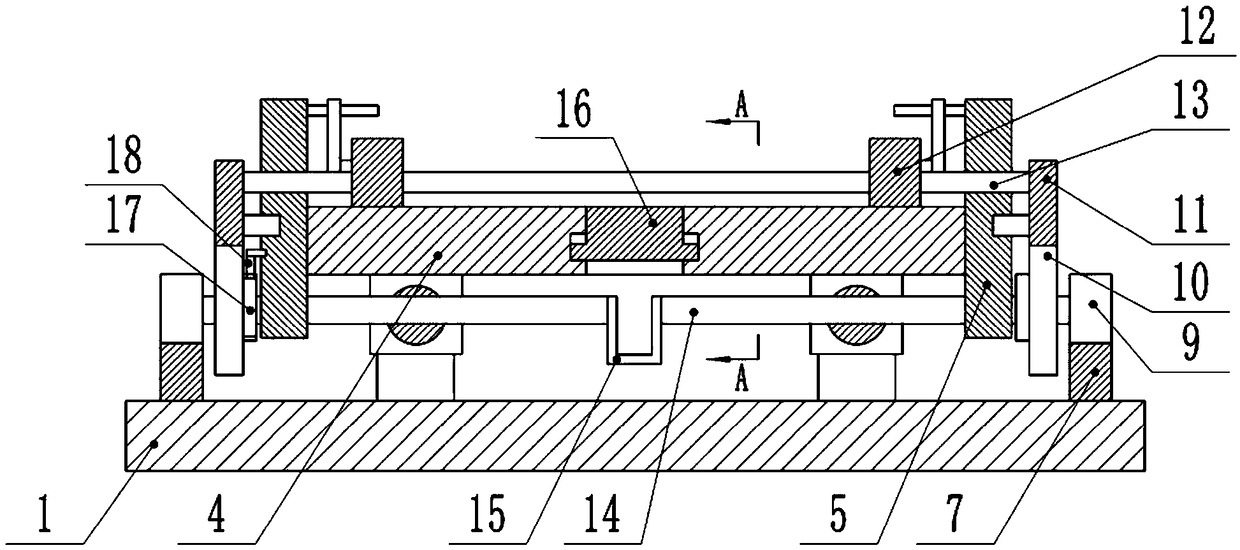

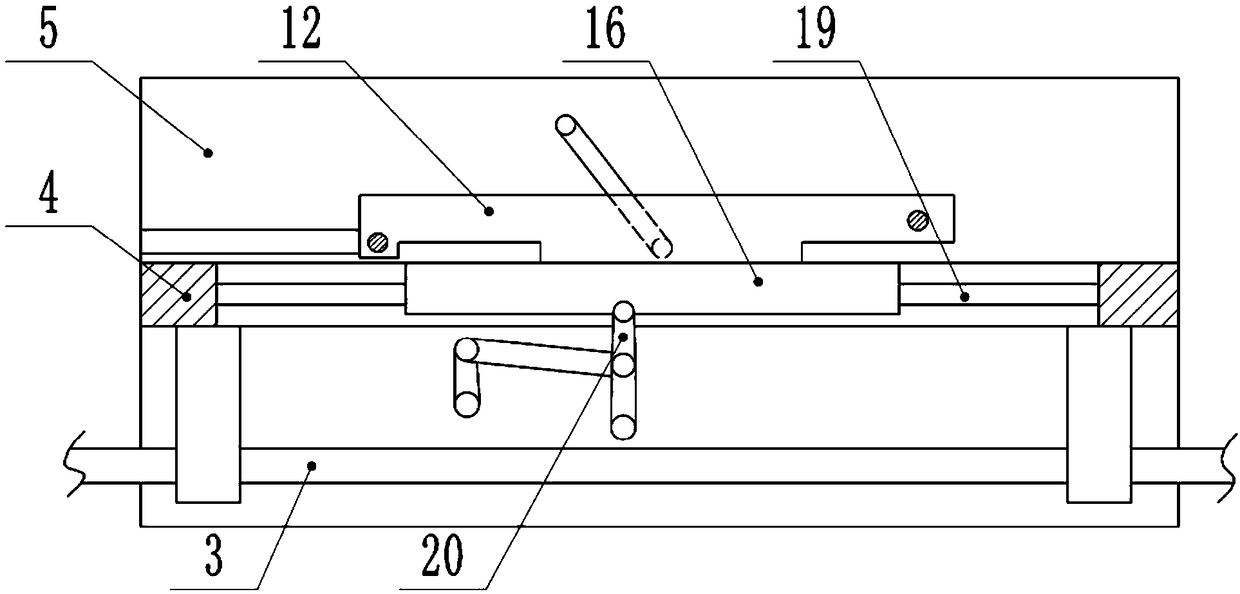

The invention belongs to the technical field of plank processing and particularly discloses a plank slotting machine. The plank slotting machine comprises a workbench, the workbench is slidably provided with a sliding plate and a power mechanism for driving the sliding plate. The sliding plate is provided with two clamping plates. A slotting mechanism is arranged above the sliding plate. First racks are arranged at the positions, on the two sides of the sliding plate, of the workbench. The two sides of the sliding plate are provided with side plates, the side plates are provided with first gears and second gears, and the side plates are slidably connected with second racks meshed with the second gears. The ends of the second racks are hinged to the clamping plates. A movable rod is hingedbetween the middle of the clamping plates and the upper portions of the side plates. The middle of the sliding plate is slidably connected with a polishing block, and the second gears are connected with transmission mechanisms for driving the polishing block to perform reciprocating movement. In the work process of the plank slotting machine, automatic turning-over of a plank can be realized, thetwo sides of the plank are subjected to slotting, and slotting efficiency is high; and meanwhile, slots formed in the plank are subjected to polishing treatment through the polishing block, and the manual labor intensity is lowered.

Description

technical field [0001] The invention belongs to the technical field of wood board processing, in particular to a wood board slotting machine. Background technique [0002] There are many wood processing operations, including cutting, nailing and other operations. For the slotting of wood boards, the current processing method is manual operation, the cutting wheel is fixed, and then the operator pushes the wood board to the cutting wheel, so that There are certain safety hazards in manual operation, and the labor intensity of the staff is high, and many wooden boards are usually slotted on both sides of the board for assembly needs, so the operation is usually After slotting one side of the board, Manually turn over the plank, and then slot the other side of the plank. The above-mentioned operation process is complicated, and the continuity of the slotting is not high, resulting in low work efficiency. Contents of the invention [0003] The object of the present invention ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B27F5/02

CPCB27F5/02

Inventor 邓月全

Owner 重庆哲骁装饰工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com