Multi-angle grinding machine for surfaces of intelligent pantograph carbon contact strips and grinding method thereof

A pantograph carbon slide, multi-angle technology, applied in the direction of grinding frame, grinding slide, grinding machine, etc., can solve the problems that the grinding device cannot be turned over automatically, increases the labor burden of workers, and cannot adjust the grinding device, etc., to achieve The effect of reducing the burden of secondary turning, reducing labor burden, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

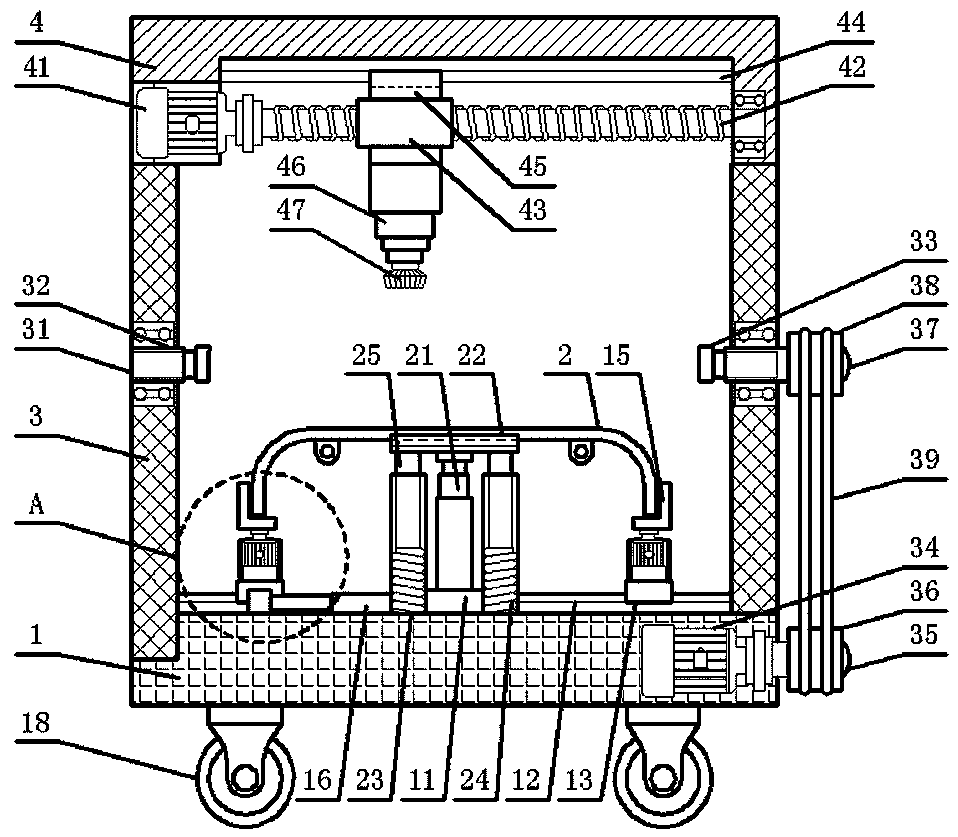

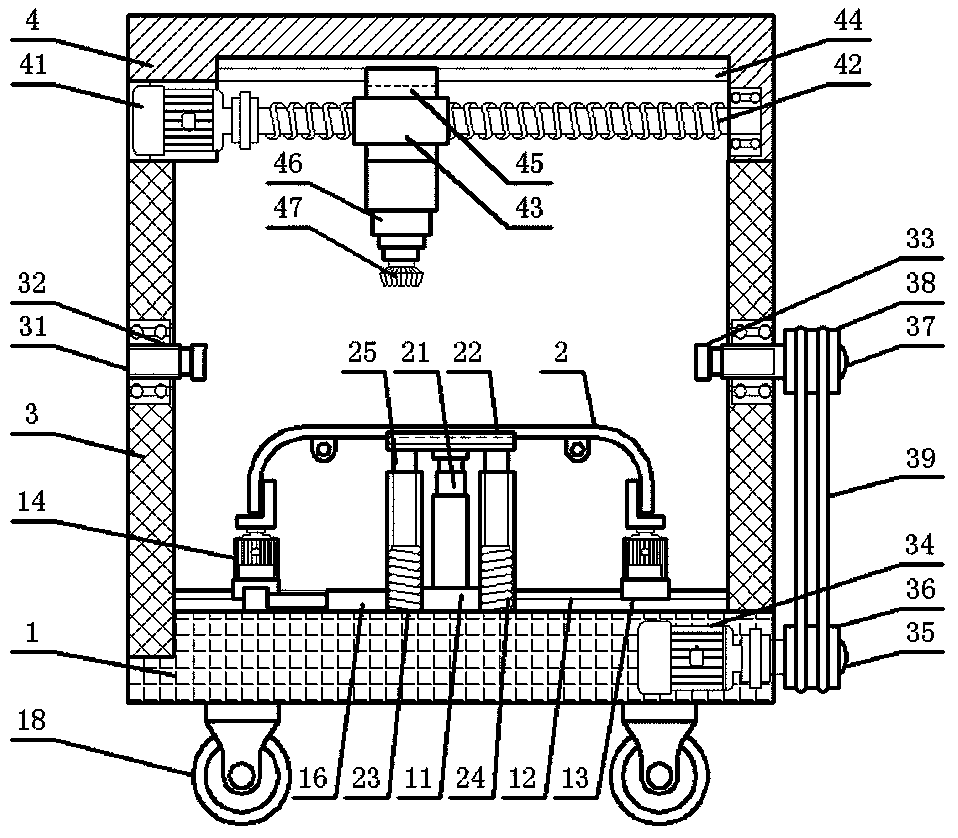

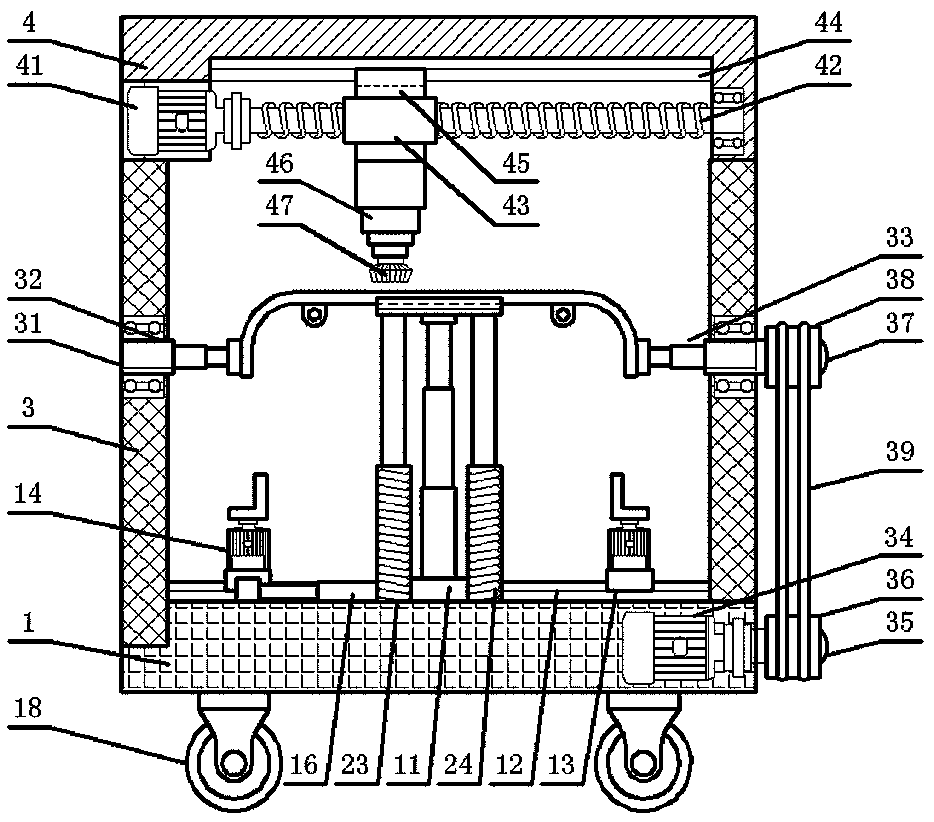

[0036] Embodiment 1: see Figure 1-5, a multi-angle grinding machine for the surface of an intelligent pantograph carbon skateboard, including a base plate 1, the base plate 1 is a rectangular long plate placed horizontally and horizontally, and the center of the top surface of the base plate 1 is provided with a fixed seat 11, and the fixed seat 11. A lifting telescopic cylinder 21 with the output end facing upwards is installed on the front. The model of the lifting telescopic cylinder 21 is DSTH CA. The telescopic cylinder end of the lifting telescopic cylinder 21 is provided with a lifting connection block. There is a support plate 22 placed horizontally and horizontally, the top surface of the support plate 22 is horizontally recessed with a support card slot, and the carbon slide plate 2 placed horizontally with the opening facing downward is clamped in the support card slot, which is located directly below the two ends of the carbon slide plate 2. The top surface of the...

Embodiment 2

[0045] Example 2: see Image 6 , in this embodiment, the present invention also proposes a grinding method for a multi-angle grinder on the surface of a smart pantograph carbon slide, comprising the following steps:

[0046] Step 1, place the carbon slide plate 2 with the opening facing down and horizontally in the support slot of the support plate 22, control the lifting and lowering of the telescopic cylinder 21, and then drive the lift of the support plate 22 and the carbon slide plate 2, and then drive the limit slide bar 25 to drive The limit spring 24 cooperates to slide in the limit slide tube 23;

[0047] Step 2: Control the expansion and contraction of the first telescopic cylinder 16 according to the distance between the two ends of the carbon slide plate 2, drive the first slider 13 to move laterally along the first slide rail 12 through the connecting block 17, and then drive the first motor 14 and the L-shaped block The plate 15 moves laterally, so that the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com