Paint spraying device for resistor machining

A resistor and connecting shaft technology, applied in the direction of spraying device, can solve the problems of time-consuming and laborious, low production efficiency, high labor cost, and achieve the effect of improving the quality of painting, simple structure, convenient disassembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

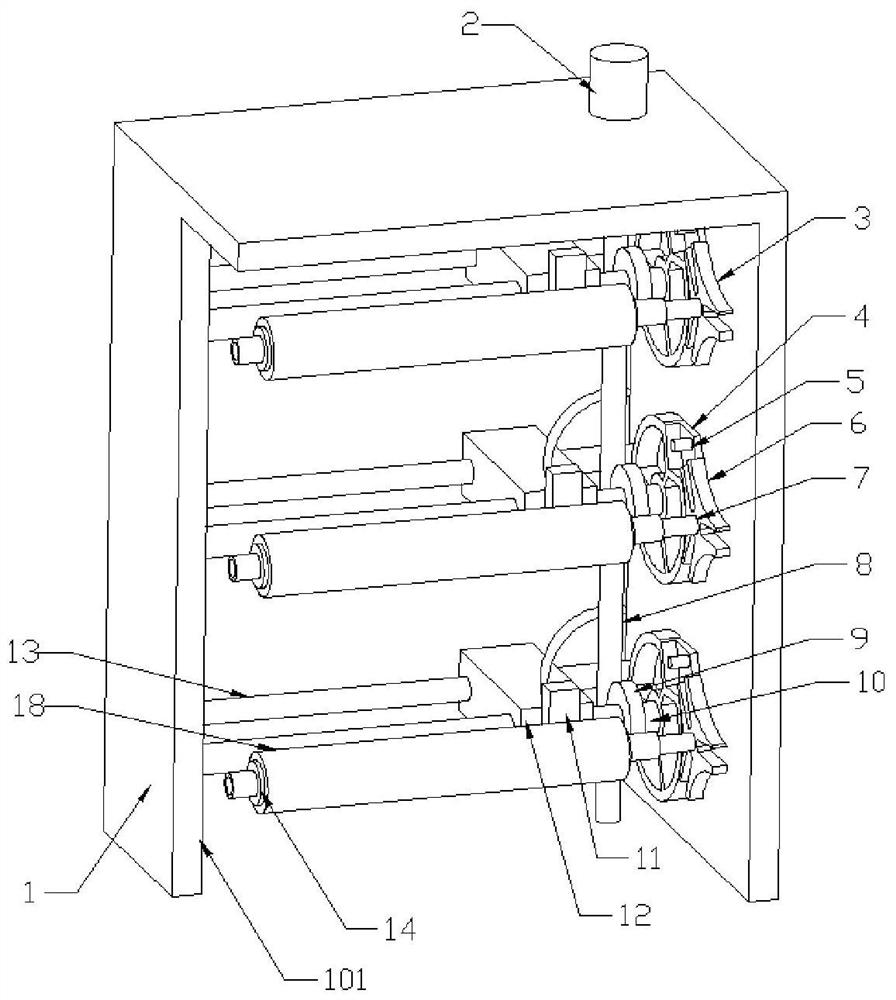

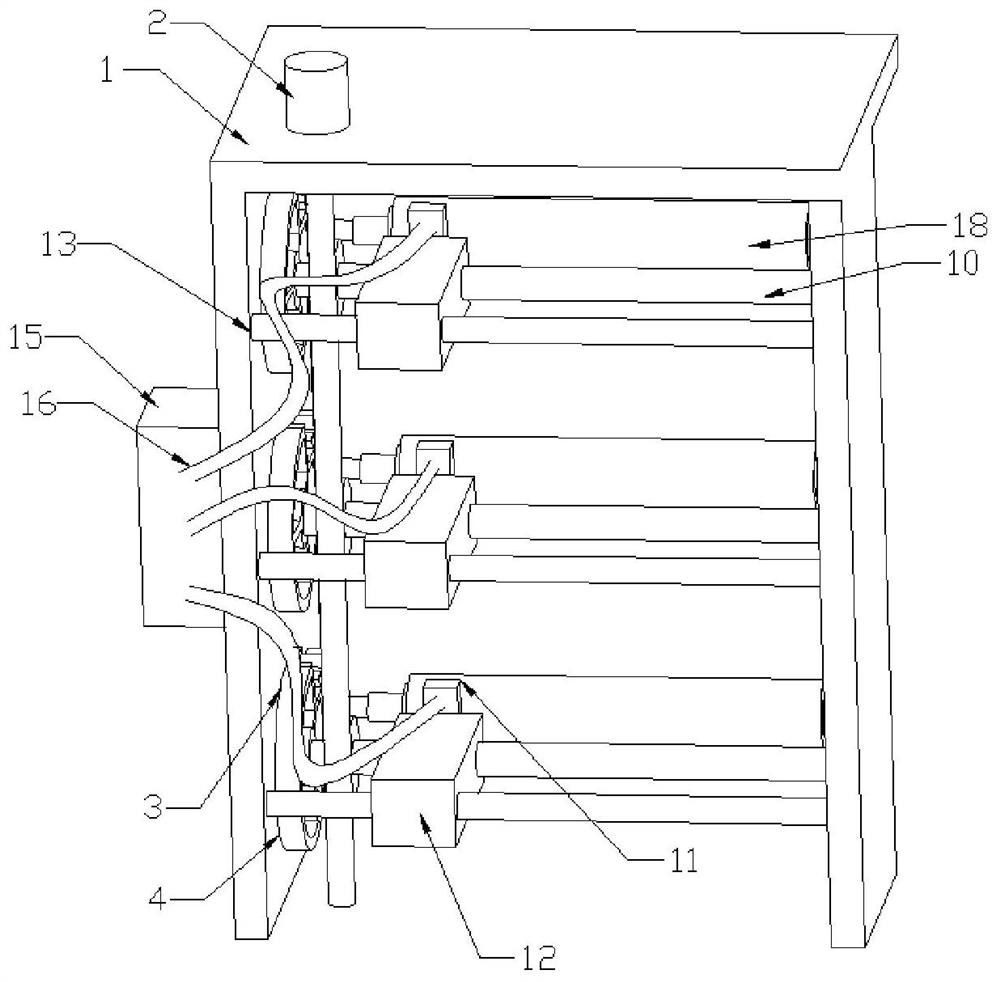

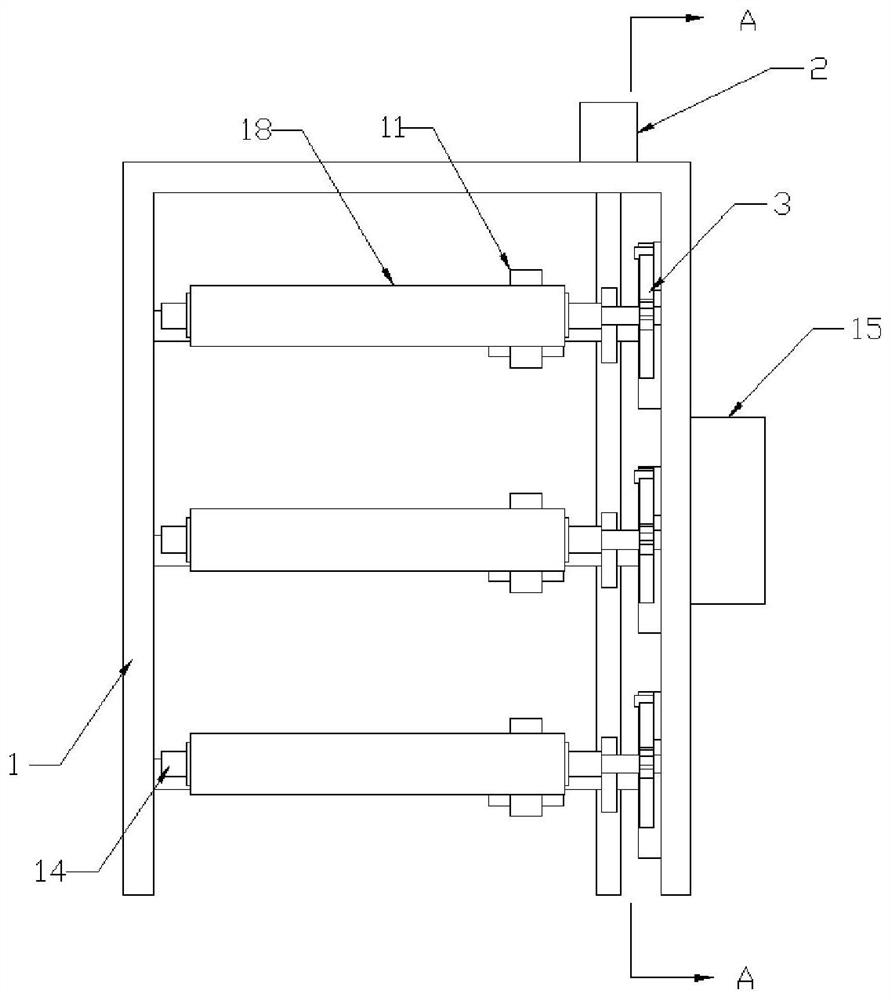

[0023] combine Figures 1 to 6 Shown, a kind of resistor 18 processing is used for painting device, and painting device comprises support 1, driving mechanism 3, painting assembly and connecting shaft 7; Connecting shaft 7, painting assembly are several; Arranged at equal intervals along the height direction, rotatably arranged on the inner wall of one side of the bracket 1 under the drive of the drive mechanism 3; each connecting shaft 7 is provided with a clamp 14 for clamping the resistor 18; each painting assembly is mounted on the drive mechanism 3 Can do horizontal reciprocating motion along the corresponding resistor 18 under the driving of , spray paint evenly.

[0024] Such as Figure 3-6 As shown, the driving mechanism 3 includes a worm 8, a sheave mechanism, a worm wheel 9, and a rotating shaft 10; the bracket 1 is U-shaped, with the opening facing downward, and the other side wall of the bracket is provided with a gap 101 corresponding to each connecting shaft, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com