Differential mesh belt type tempering furnace

A tempering furnace and mesh belt type technology are applied in the field of tempering treatment devices for metal parts after quenching, which can solve problems such as the inability to achieve uniform heating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

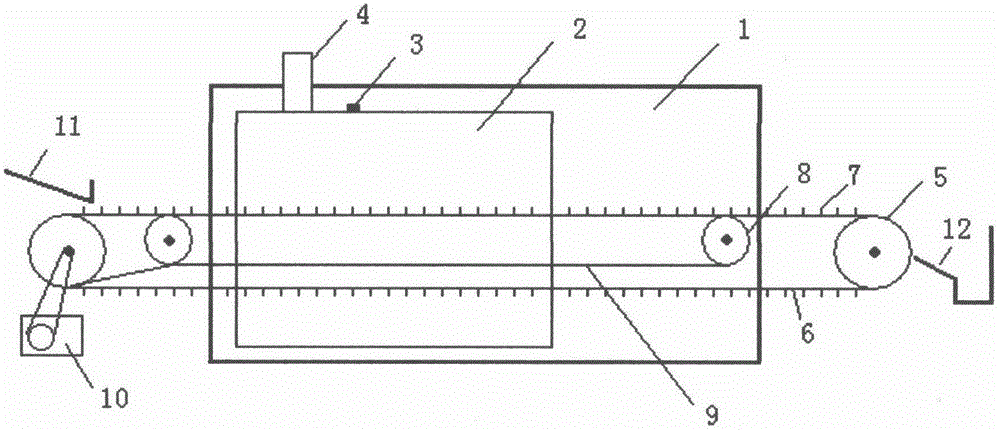

[0007] Such as figure 1 As shown, a differential speed mesh belt tempering furnace consists of a tempering furnace body (1), a heating section (2), a thermocouple (3), a circulating fan (4), a main sprocket (5), and a main chain mesh belt (6), baffle plate (7), secondary sprocket wheel (8), secondary chain mesh belt (9), transmission system (10), feed table (11) form.

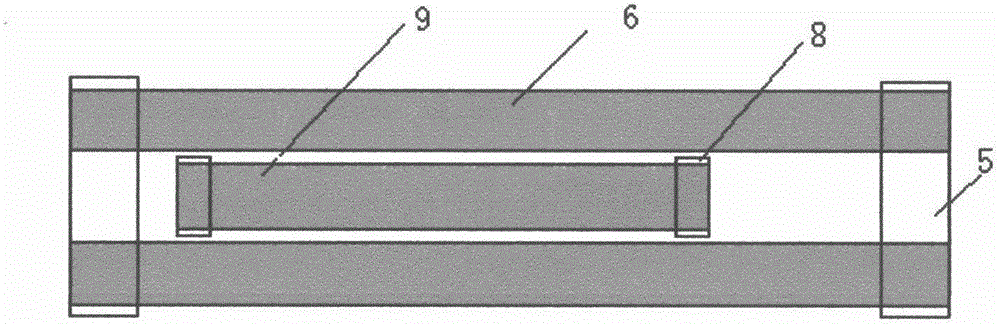

[0008] Two main chain mesh belts (6), main sprocket wheel (5) and baffle plate (7) form a loop, and the secondary chain mesh belt (9) and secondary sprocket wheel (8) form a loop, and the secondary chain mesh belt is located at the two In the middle of the main chain mesh belt (such as figure 2 shown); the middle part of the rod-shaped tempering piece is placed on the secondary chain mesh belt, and the two ends are separated by the baffle of the main mesh belt; the transmission system (10) is connected with the main sprocket (5) and controls the tempering piece in the furnace The passing speed; the main spro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com