Aluminum alloy plate paint spraying equipment for industrial production

A painting equipment and aluminum alloy plate technology, which is applied in the direction of spraying devices, liquid spraying devices, etc., can solve the problems of insufficient spraying speed and inability to carry out all-round spraying, and achieve the effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

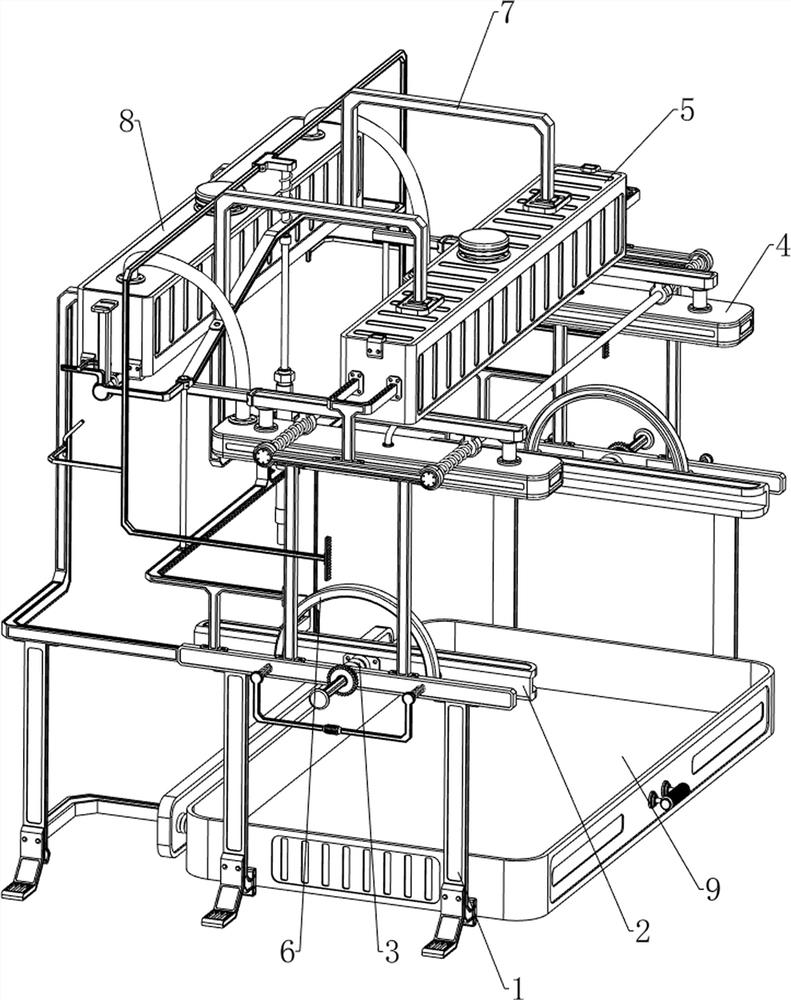

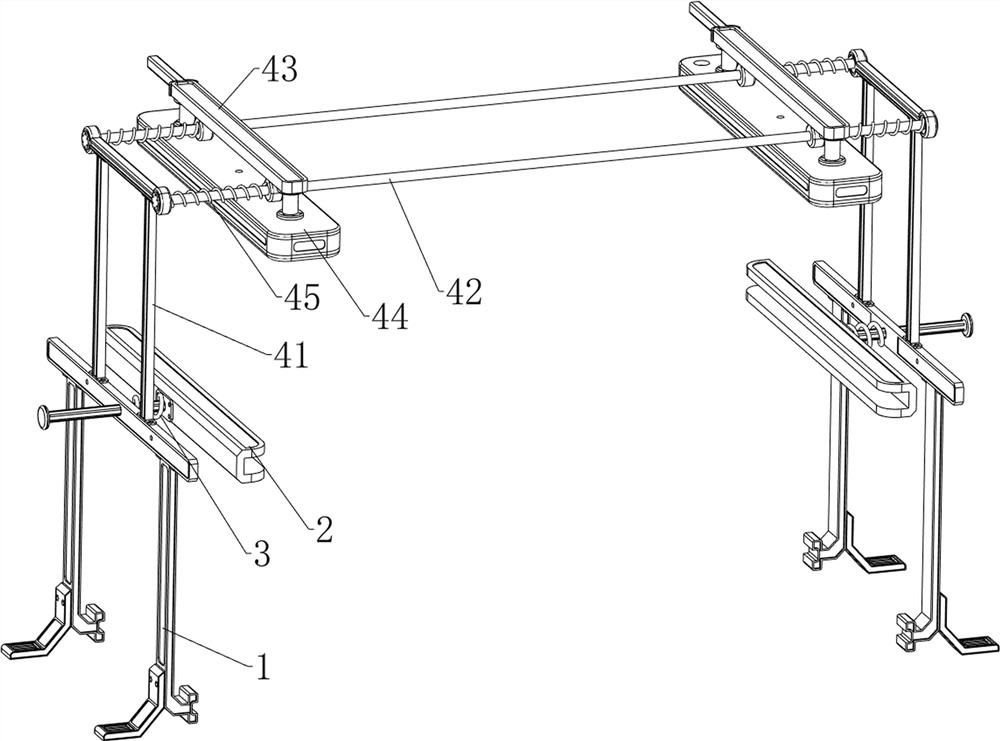

[0036] A kind of aluminum alloy plate spraying equipment for industrial production, such as Figure 1-17 As shown, it includes a first bracket 1, a clamping block 2, a compression spring 3, a spraying mechanism 4 and a feeding mechanism 5. The upper parts of the two first brackets 1 are movably provided with a clamping block 2, and the first bracket 1 The inner side is provided with a compression spring 3, the compression spring 3 is matched with the clamping block 2 correspondingly, and a spraying mechanism 4 is arranged between the top of the first bracket 1, and a feeding mechanism 5 is arranged on the spraying mechanism 4 parts.

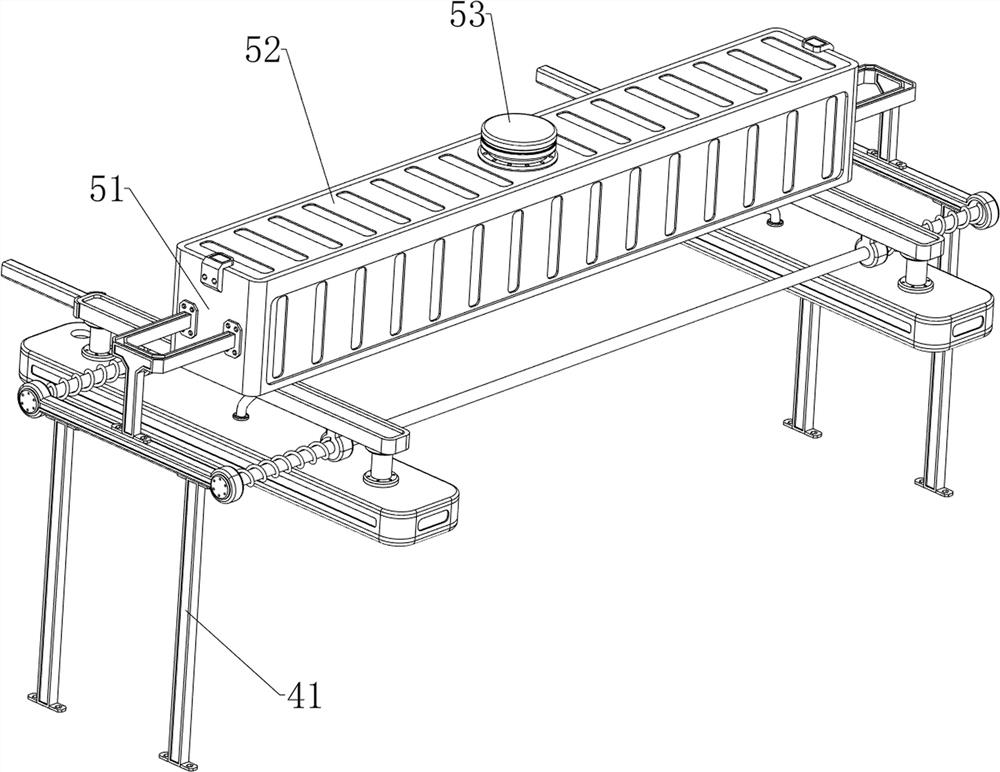

[0037] The spraying mechanism 4 includes a second bracket 41, a first connecting rod 42, a first connecting block 43, a spray head 44 and a first return spring 45. The top of the first bracket 1 is provided with a second bracket 41, and the upper part of the second bracket 41 is provided with a second bracket 41. There are two first connecting ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com