Simple sample crushing device and operation method thereof

A technology of sample crushing and operation method, which is applied in the shale sample crushing device and the field of simple coal, can solve the problems of poor dust operation environment, poor crushing effect, operator injury, etc., so as to improve the crushing effect and The effect of crushing efficiency, simple structure, time-saving and labor-saving operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

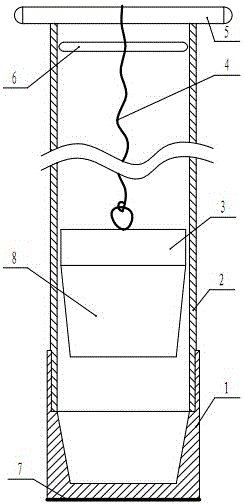

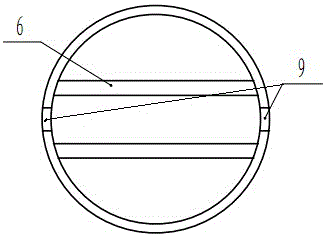

[0028] Embodiment 1: as Figure 1~Figure 3 As shown, a simple sample crushing device includes a cylindrical crushing cylinder 1, a guiding cylinder 2 and a cylindrical crushing hammer 3. The crushing cylinder 1 is provided with a guiding cylinder 2, and the lower end of the guiding cylinder 2 is embedded in the crushing cylinder 1. inside, and against the steps in the crushing tube 1 to achieve positioning, the breaking hammer 3 is placed in the guide tube 2, and can move to the bottom of the crushing tube 1, and the upper end is connected with a steel wire 4, and the breaking hammer 3 is placed in the crushing tube 1 At the bottom, the steel wire 4 can pass through the upper end of the guide cylinder 2, and its length is greater than the length of the guide cylinder 2. The length of the steel wire 4 is greater than the length of the guide cylinder 2 + 500mm. The length of the guide cylinder 2 is more than ten times the height of the crushing cylinder 1, so that when the break...

Embodiment 2

[0030] Embodiment 2: A kind of operation method of simple sample crushing device, this method comprises the following steps:

[0031] (1) Place the sample in the crushing cylinder, and the amount of crushing should not exceed the steps inside the crushing cylinder;

[0032] (2) Connect the steel wire of the breaker, pass the steel wire through the space between the two bars at the upper end of the guide cylinder, and connect the steel wire to the grip bar;

[0033] (3) Put the breaking hammer in the crushing cylinder, and insert the guiding cylinder into the crushing cylinder, the length of the guiding cylinder is more than ten times the height of the crushing cylinder, and fix the guiding cylinder;

[0034] (4) Hold the grip bar with both hands to lift the breaker, raise the guide tube by half the height distance, and then quickly place the grip bar in the placement groove set on the upper end of the guide tube, and the breaker falls freely to the sample;

[0035] (5) After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com