Automatic production line and production process of solid wood cabinet plate

A technology for automated production lines and cabinets, applied in wood processing appliances, manufacturing tools, grinding feed motion, etc., can solve the problems of low degree of automation, large labor consumption, increased cost, etc., to improve the degree of automation, save space, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

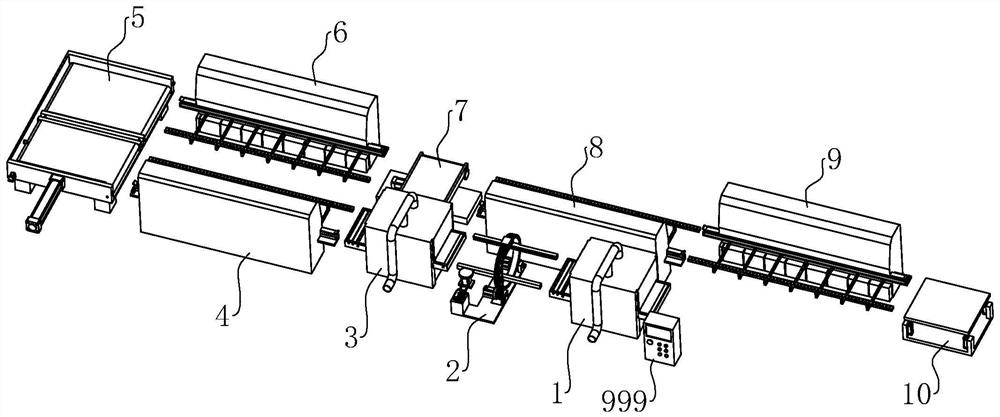

[0060] The following is attached Figure 1-8 The application is described in further detail.

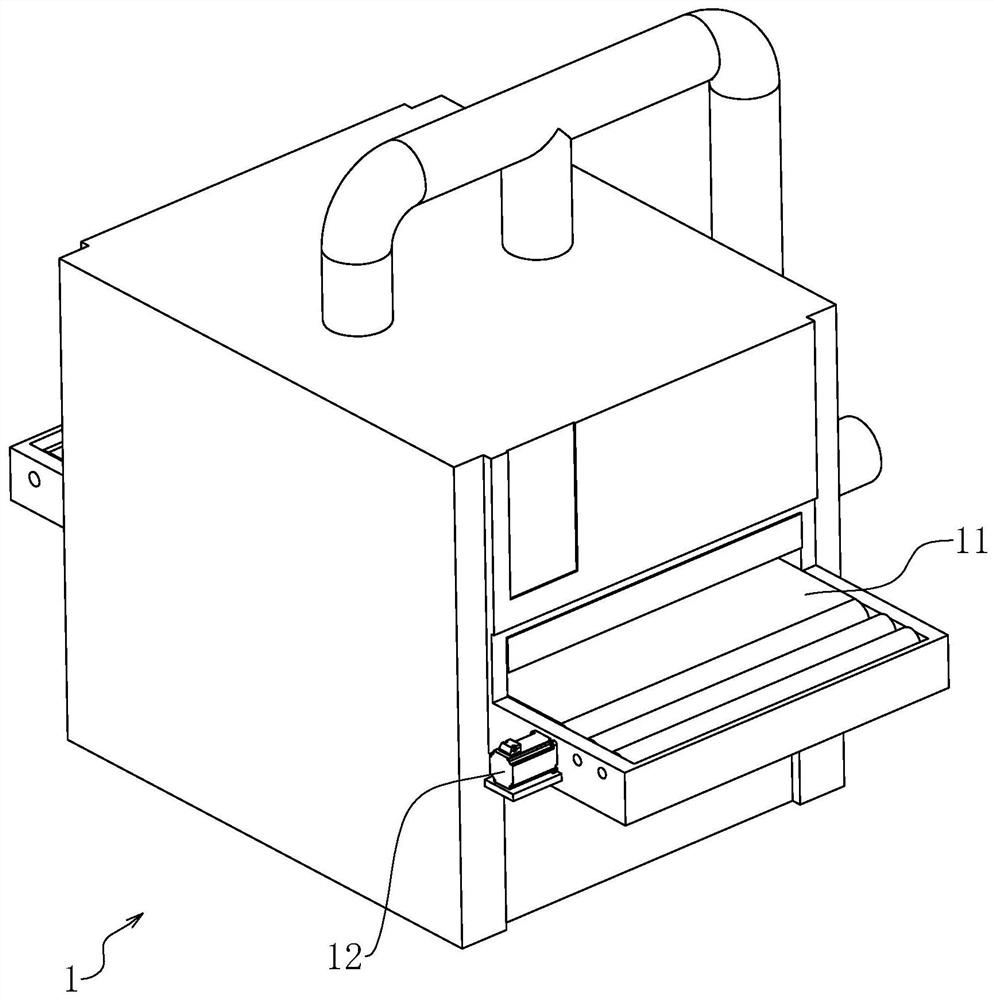

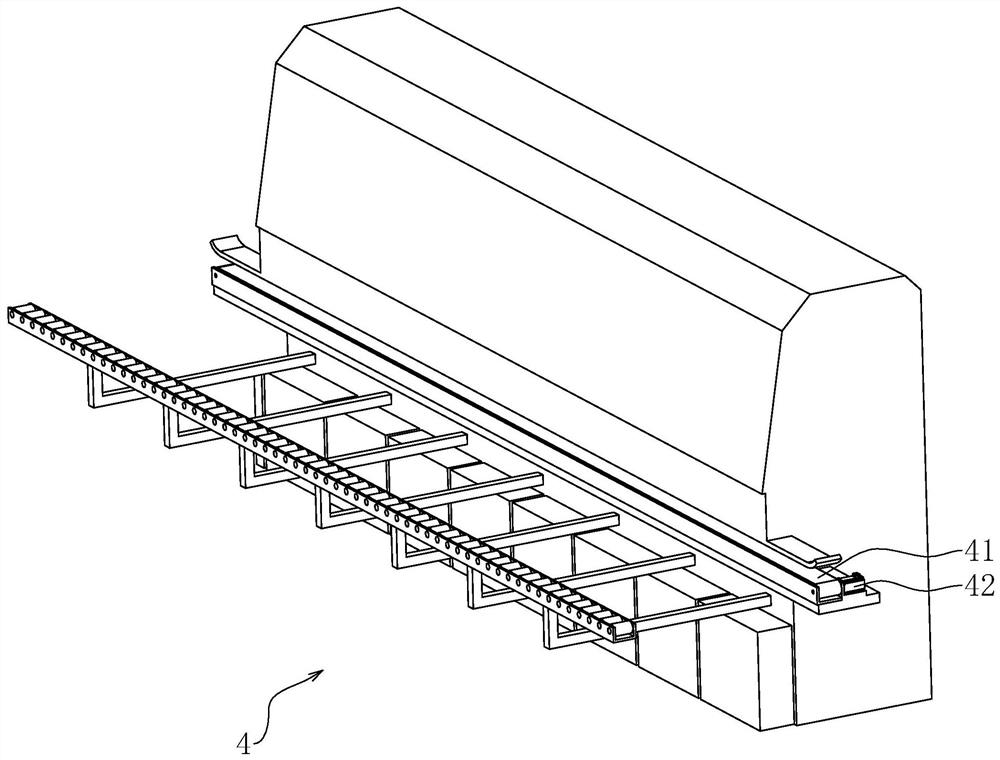

[0061] The first sander 1 and the second sander 3 use sanders with the same shape and structure, taking the first sander 1 as an example. The first sander 1 includes a sanding conveyor belt 11 for driving the plate to move and a sanding driver 12 for driving the sanding conveyor belt 11 to rotate. The two ends of the sanding conveyor belt 11 are respectively located at the feeding end and the discharging end of the first sanding machine 1, the sanding drive 12 is connected with the body of the first sanding machine, the output end is connected with the sanding conveyor belt 11, and the sanding drive 12 Set to spin the motor. After starting the sanding driver 12, the sanding driver 12 drives the sanding conveyor belt 11 to rotate. After the worker puts the plate on the feeding end of the first sanding machine 1 , the plate contacts the sanding conveyor belt 11 , and is transported ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com