Antibacterial, hydroscopic and perspiratory polyester fiber with self-hydrophilicity

A technology of moisture absorption and perspiration and polyester fiber, which is applied in the field of preparation of special-shaped polyester fibers, which can solve the problems of non-absorbency and perspiration and antibacterial, loss of fabric characteristics, distortion of fiber characteristics, etc., achieve obvious antibacterial effect, improve moisture absorption and perspiration efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

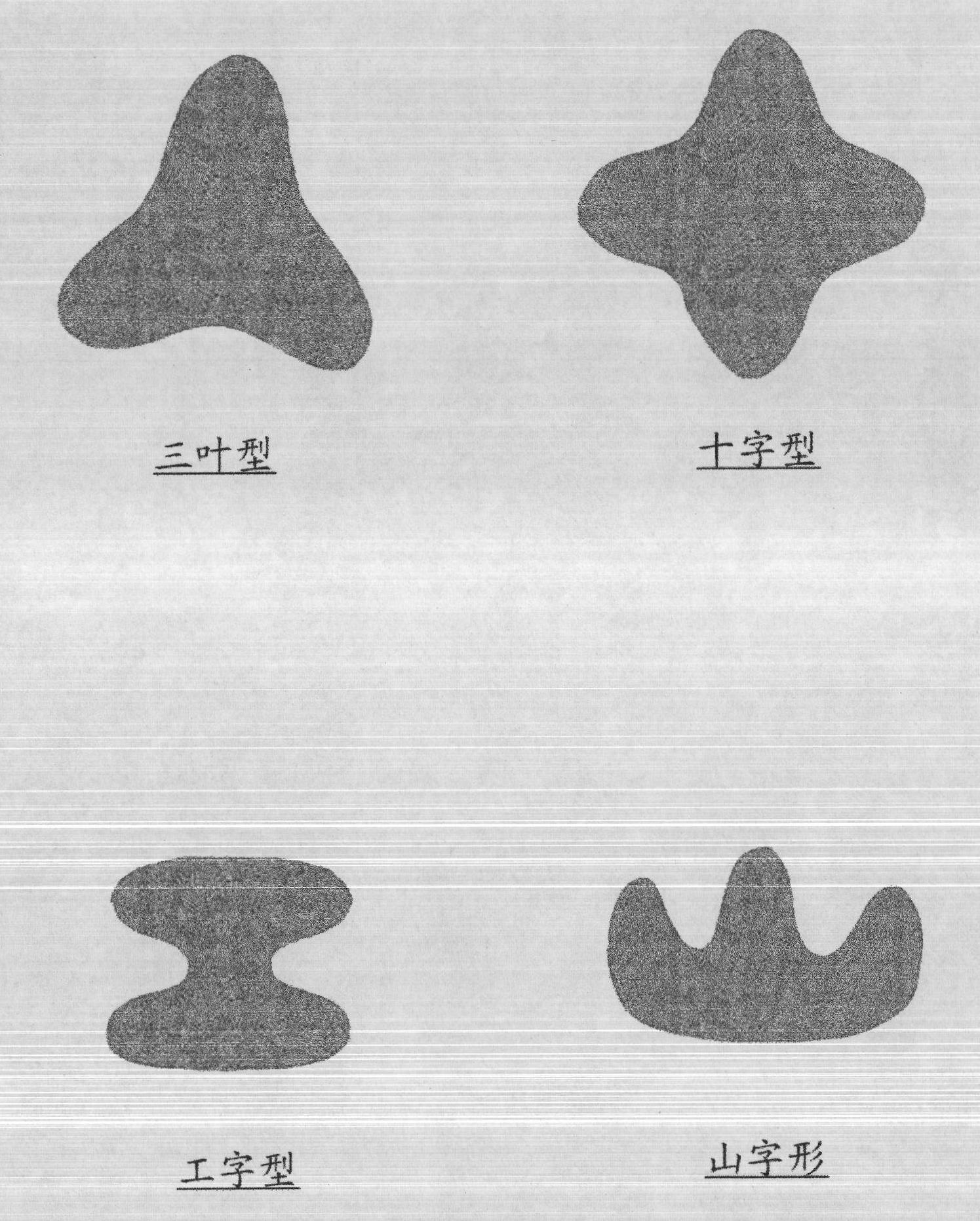

[0016] After polyester A, hydrophilic modified polyester masterbatch B and antibacterial polyester masterbatch C raw materials are sliced and dried, they are fed into the screw for blending and melting at a mass percentage of 60:20:20, in which silver, copper, and zinc ionophores are antibacterial The weight of the agent accounts for 6% of the total weight of the fiber. After being metered by a metering pump, it is input into the spinning box (295° C. of spinning temperature), extruded by a special-shaped spinneret with a three-lobed plate hole, blown and cooled, and drawn ( Drawing temperature 90 ℃, drafting ratio 3.0 times), setting (temperature 120 ℃), winding (speed 5000m / min), made hydrophilic trilobal polyester FDY filament with antibacterial function.

Embodiment 2

[0018] After the raw materials of polyester A, hydrophilic modified polyester masterbatch B and antibacterial polyester masterbatch C are sliced and dried, they are input into the screw for blending and melting according to the mass percentage of 93:5:2, and the silver, copper, and zinc ionophores are antibacterial The weight of the agent accounts for 1% of the total weight of the fiber. After being metered by a metering pump, it is input into the spinning box (spinning temperature 295 ° C), extruded from a special-shaped spinneret with cross-shaped plate holes, blown and cooled, and wound (speed 1200m / min). The winding POY yarn is stretched and stretched (drawing temperature 170°C, drafting ratio 1.6 times), and the hydrophilic cross-shaped polyester DTY filament with antibacterial function is obtained.

Embodiment 3

[0020] After the raw materials of polyester A, hydrophilic modified polyester masterbatch B and antibacterial polyester masterbatch C are sliced and dried, they are input into the screw for blending and melting at a mass percentage of 80:15:5, and the silver, copper, and zinc ionophores are antibacterial The weight of the agent accounts for 2% of the total weight of the fiber. After being metered by the metering pump, it is input into the spinning box (spinning temperature 280 ° C), extruded from the special-shaped spinneret with the I-shaped plate hole, blown and cooled, and wound (speed 1000m / min), falling into the drum, the yarn bundled in the falling drum, and then through two stages of drafting: the first stage of drafting (drawing temperature 80°C, drafting multiple 3.5 times), the second stage of drafting (drawing temperature 110°C, drafting elongation 1.1 times), the fiber is crimped, and subjected to a relaxation heat setting treatment at 120°C for 60 minutes, then s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com