Horizontal type or obliquely horizontal type roller washing machine

A drum washing machine, inclined horizontal technology, applied in the washing machine field, can solve the problems of inconvenient use, waste, installation and disassembly, etc., and achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

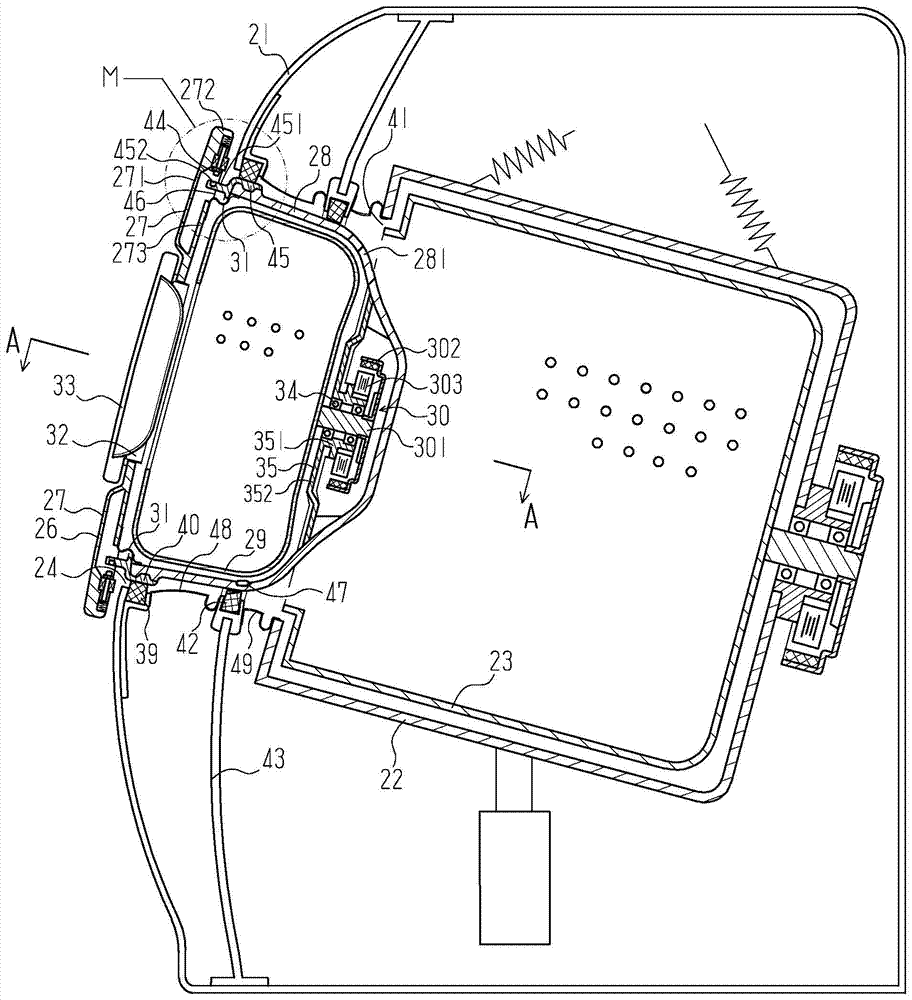

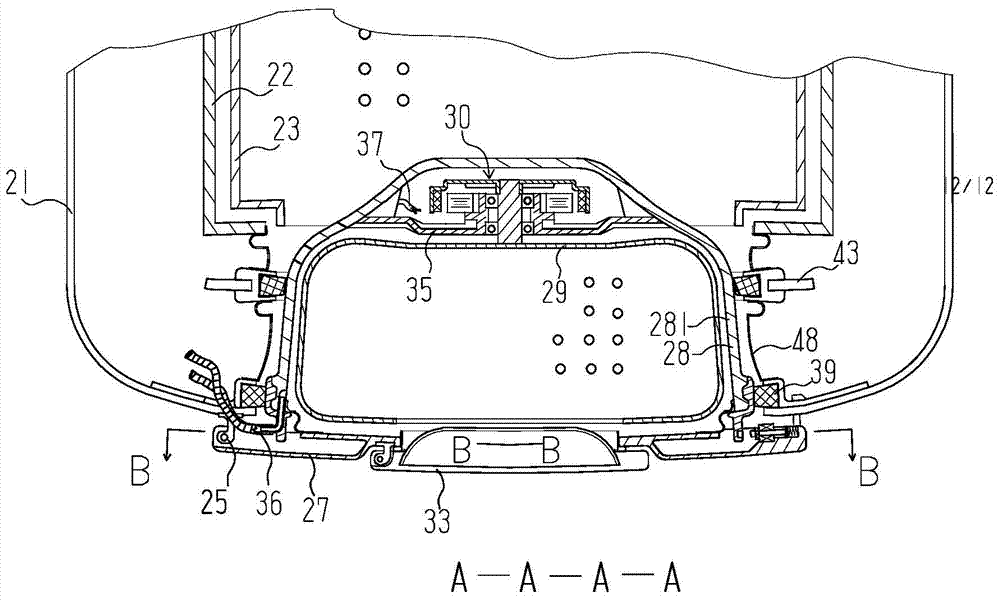

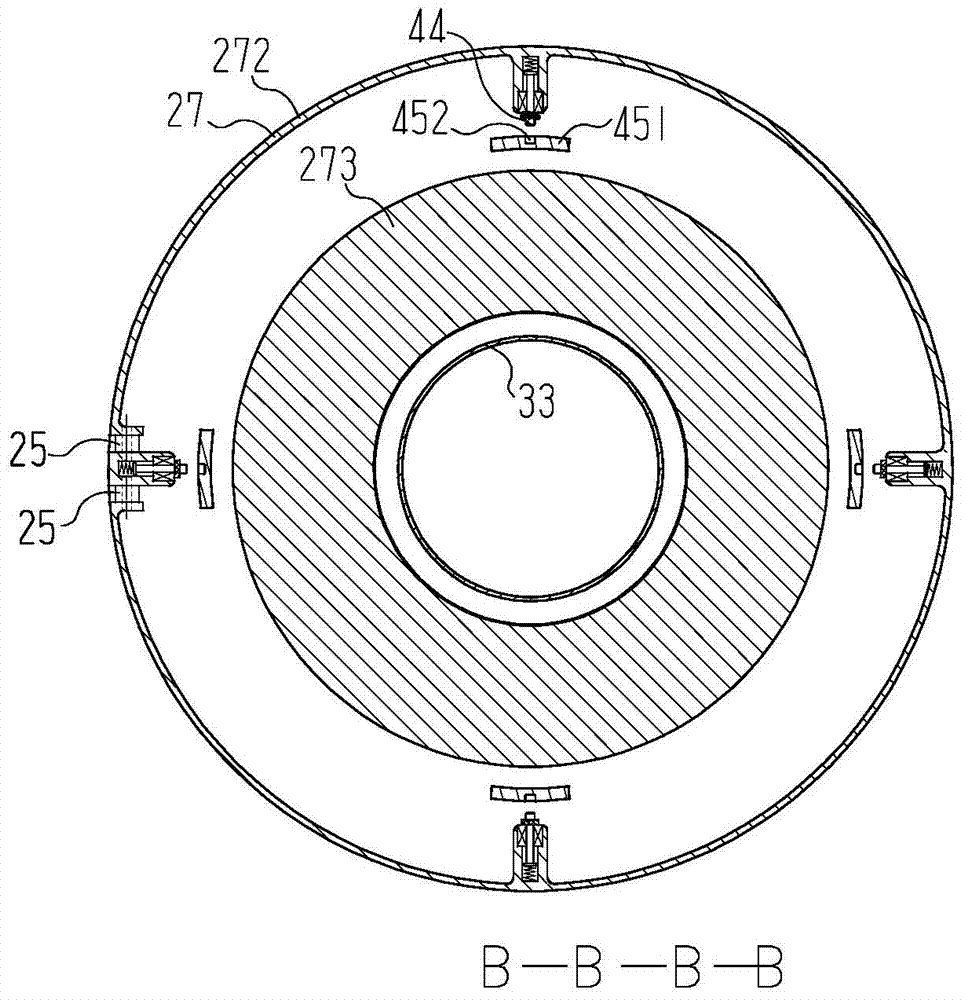

[0042] Figure 1 to Figure 7 Embodiment 1 of the present invention is shown. An oblique drum washing machine comprises an outer case (21), a water tub (22) in the outer case, and a rotating drum (23) in the water tub. The front part of the outer box has a material opening (24) for clothing to enter and exit the rotating drum (23), and the front part of the outer box is also provided with a door cover (26) hinged to the outer box that can close or open the material opening (24). ). Door cover (26) is hinged on the front part of outer box by hinge (25), Figure 5It shows that the door cover (26) is in the state of opening the material opening of the outer box.

[0043] The door cover (26) includes a front cover part (27) with a front panel (271), and a rear cover part (28) with a convex basin (281).

[0044] The described front cover part (27) and the rear cover part (28) not only have the connected state that the rear cover part (28) is fixedly supported by the front cover ...

Embodiment 2

[0064] Figure 8 The inclined drum washing machine shown;

[0065] The difference with the washing machine in Embodiment 1 is that the bearing seat (51) of the drive motor (30) that drives the rotary drum (29) to rotate is fixed on the back of the convex basin (281) of the rear cover (28). On the rear outer wall (282), a cover (50) is also arranged on the rear outer wall (282) to cover the drive motor part.

Embodiment 3

[0067] Figure 9 , Figure 10 The inclined drum washing machine shown;

[0068] The difference from the washing machine in Embodiment 1 is that the front end of the kyphotic basin (281) here is the front end of the back cover (28), and the front end of the kyphosis (281) directly extends into the front In the space within the rear bottom surface (56) of the cover peripheral portion (272) of the cover portion (27), the front end and the adjacent rigid parts of the front cover portion are all non-contact and separated with gaps.

[0069] In the cover peripheral portion (272) of the front cover portion (27), four motor-driven movable connectors (52) that are uniformly distributed on the circumference and rotate around the shaft, namely the connecting buckle (52) are arranged here; The front end of the cover part (28) is correspondingly provided with a fastening part (55) matching with the connecting buckle (52) and receiving the connecting buckle. The fastening part (55) here ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com