Preparation method of high-dispersivity graphene

A high-dispersion, graphene technology, applied in the field of graphene preparation, can solve the unavoidable problems of chemical reagents, etc., and achieve the effects of good stability, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A kind of preparation method of highly dispersed graphene,

[0017] 1), the preparation of graphite oxide: take 1.5g of flake graphite powder, 1.5g of sodium nitrate, 70ml of concentrated sulfuric acid with a mass concentration of more than 70%, add them to the there-necked bottle successively, stir evenly under ice bath conditions, slowly add 9g of high manganese Then warm up to room temperature for 2 hours, then add 100ml of distilled water, then heat up to 90°C for 1 hour; then add 300ml of distilled water and 10ml of 30% H to the reaction system 2 o 2 ; Then centrifuge the above solution several times, wash it several times with dilute hydrochloric acid, distilled water and absolute ethanol successively, the pH value is close to neutral, and dry the product at 80°C to obtain graphite oxide;

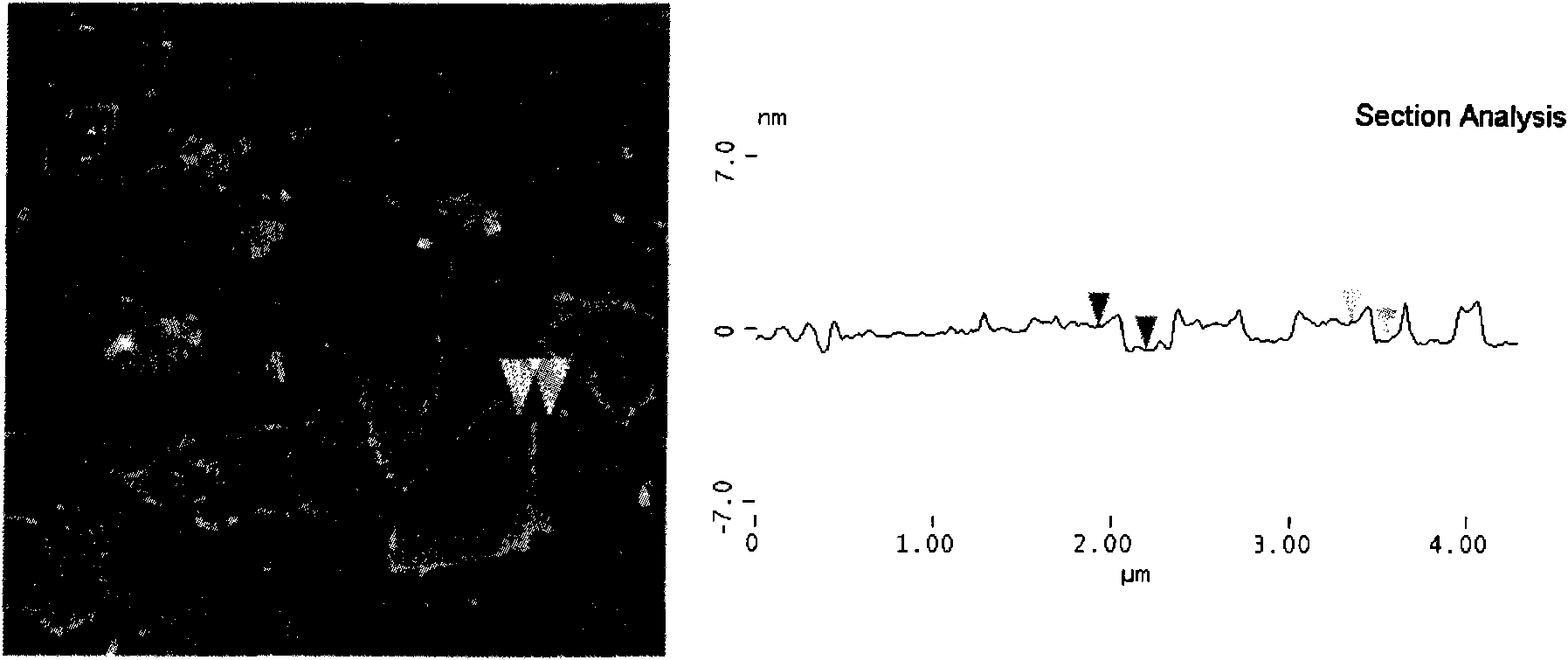

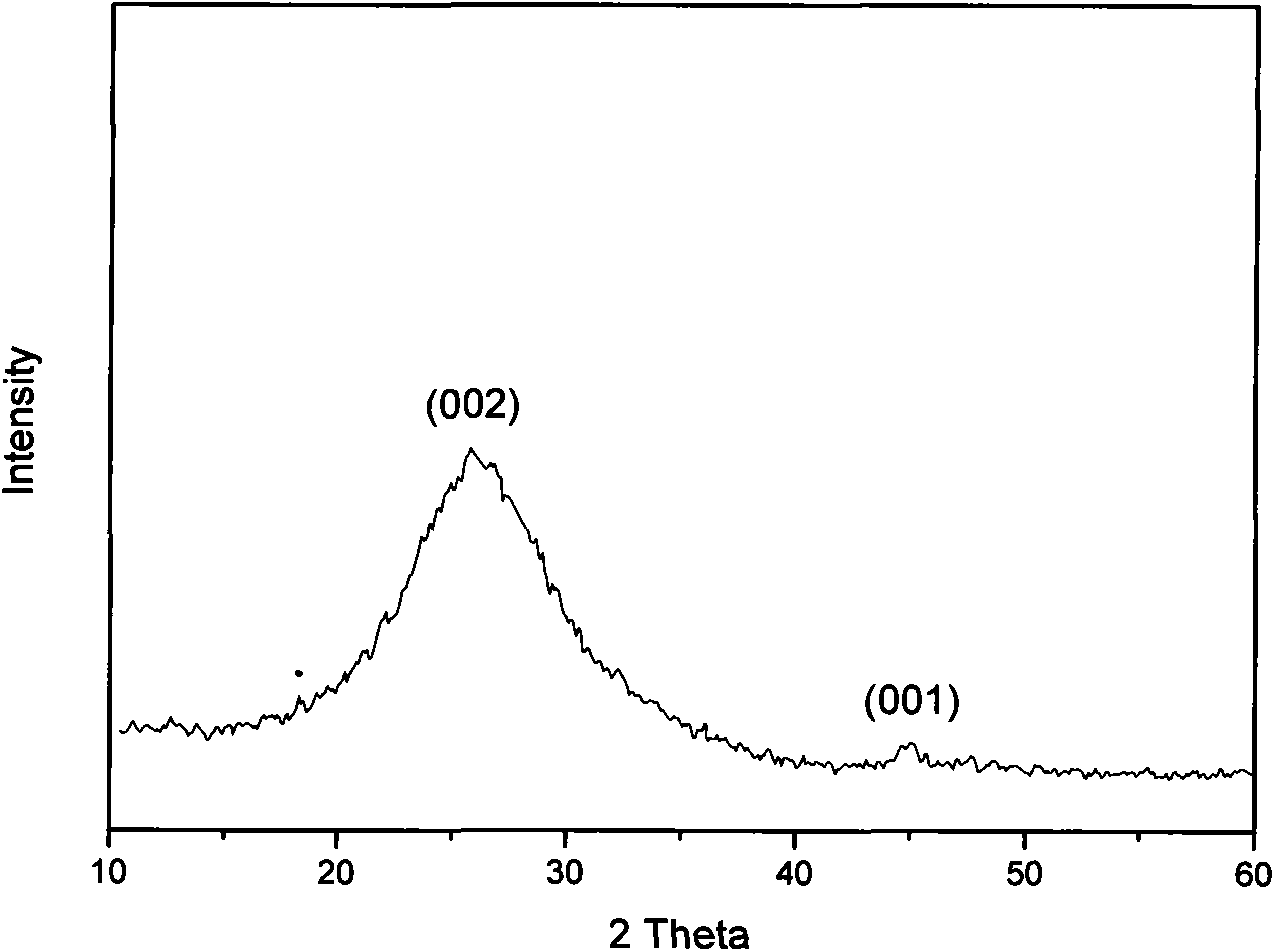

[0018] 2), the preparation of highly dispersible graphene: get the graphite oxide of 10mg to disperse in the distilled water of 50ml, ultrasonic stripping obtains the aqueous ...

Embodiment 2

[0021] .1), the preparation of graphite oxide is identical with embodiment 1. .

[0022] 2), the preparation of highly dispersible graphene: get the graphite oxide of 10mg to disperse in the distilled water of 50ml, ultrasonic stripping obtains the aqueous solution of graphene oxide, adds the polyvinyl alcohol (PVA, molecular weight 30000) of 15mg, then in ultraviolet lamp ( 254nm, 125W) under light irradiation for 48 hours. A black stable graphene dispersion is obtained. Then the above dispersion liquid was filtered, washed several times with distilled water, and dried at 50° C. to obtain highly dispersed graphene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com