Environment-friendly single-layer microcellular foam PVC (polyvinyl chloride) wood-plastic composite board and preparation method thereof

A micro-foaming and environmentally friendly technology, applied in the field of composite panels, can solve the problems of easy deformation of plastic panels in storage, less use of wood panels, and unsatisfactory use effects, etc. The effect of improving the surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

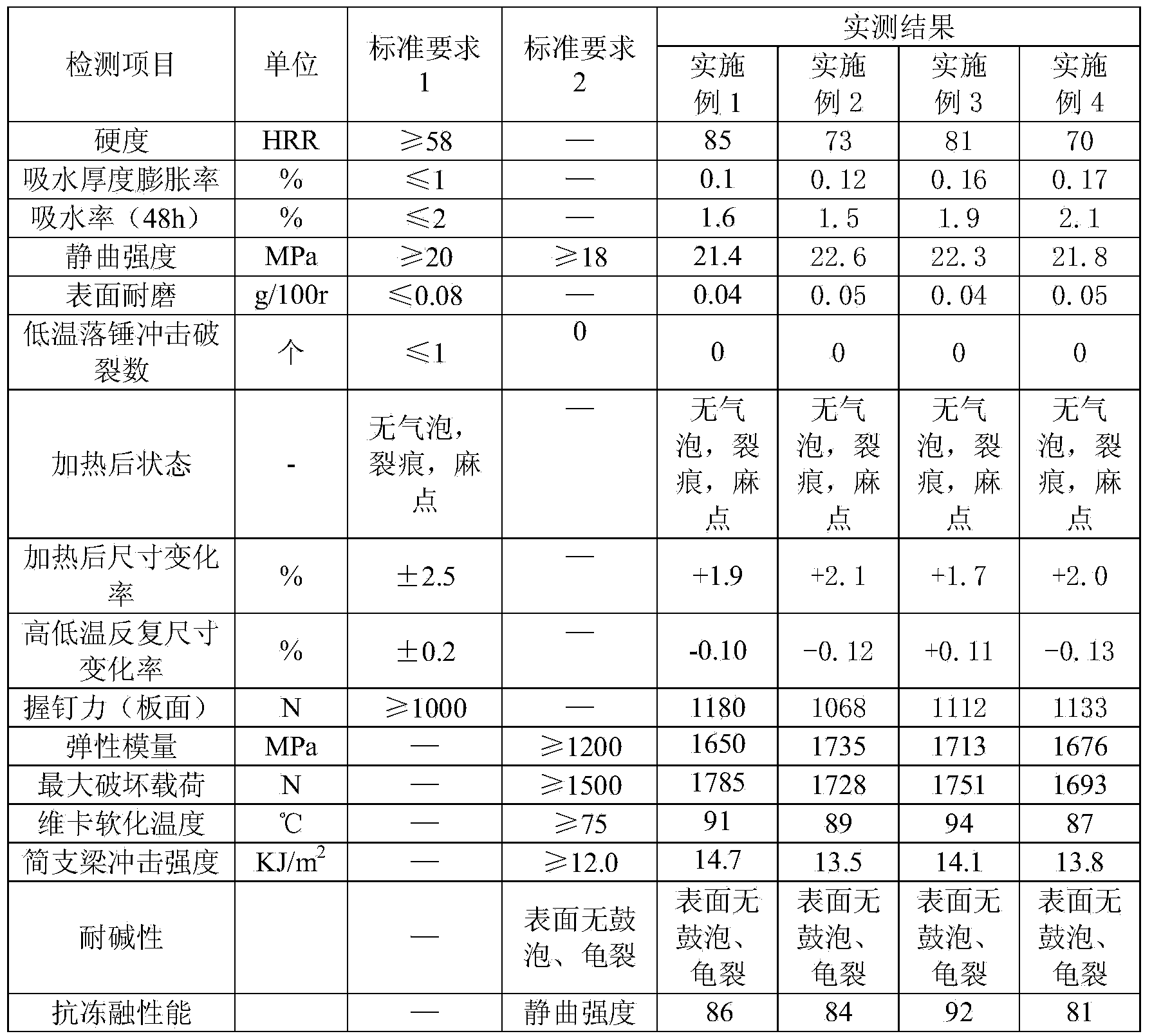

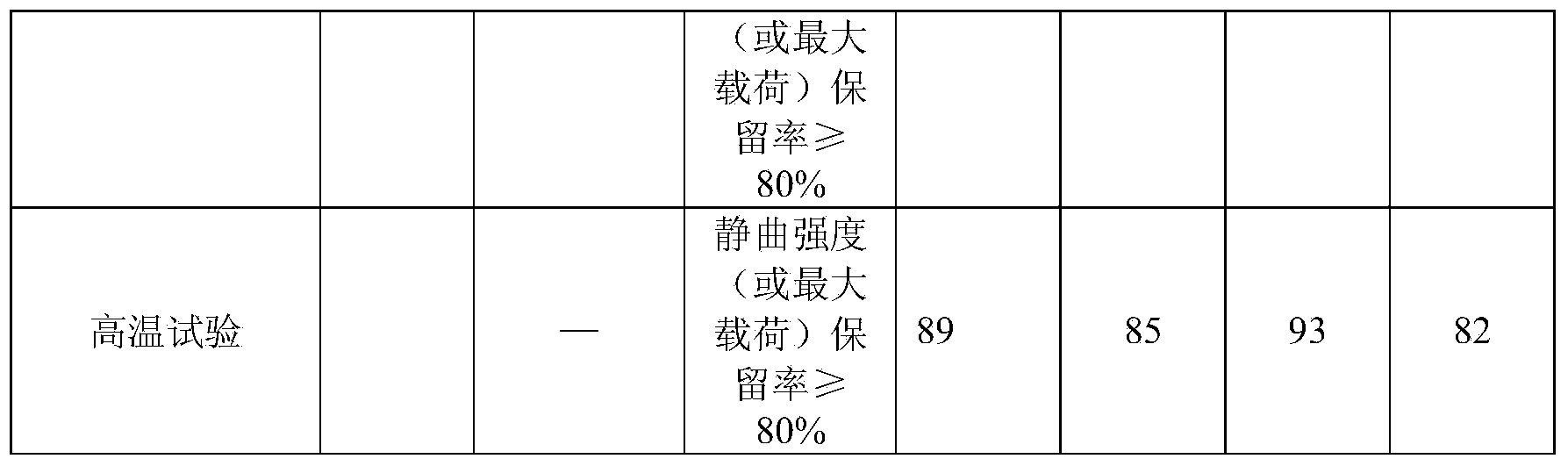

Examples

Embodiment 1

[0046] An environment-friendly single-layer micro-foamed PVC wood-plastic composite board, the mass ratio of each component in the raw material formula used is as follows:

[0047] 20% polyvinyl chloride recycled material, 45% polyvinyl chloride resin, 10% wood fiber powder, 8.5% filler, 4% foam regulator, 1.4% composite stabilizer, 0.7% foaming agent, 2.5% reinforcing agent, 2.4% impact modifier, 0.35% lubricant, 0.15% coupling agent, 1% colorant, 2% anti-aging agent and 2% flame retardant.

[0048] In this embodiment, the above polyvinyl chloride recycled materials are PVC door and window powder, PVC pipe powder, PVC trademark paper powder, PVC floor powder, PVC film powder, PVC decorative board powder, PVC building formwork powder One or more of them, and the powder particle size of the polyvinyl chloride recycled material is 80 mesh.

[0049] The above lignocellulosic powder is one or more powders of rice husk powder, peanut shell powder, straw powder, corncob powder, pla...

Embodiment 2

[0069] An environment-friendly single-layer micro-foamed PVC wood-plastic composite board, the mass ratio of each component in the raw material formula used is as follows:

[0070] 60% polyvinyl chloride recycled material, 15% polyvinyl chloride resin, 5.7% wood fiber powder, 5.4% filler, 4.1% foam regulator, 1% composite stabilizer, 0.9% foaming agent, 2.1% reinforcing agent, Impact modifier 2.24%, lubricant 0.45%, coupling agent 0.11% and colorant 3%.

[0071] In this embodiment, the above polyvinyl chloride recycled materials are PVC door and window powder, PVC pipe powder, PVC trademark paper powder, PVC floor powder, PVC film powder, PVC decorative board powder, PVC building formwork powder One or more of them, and the powder particle size of the polyvinyl chloride recycled material is 20 mesh.

[0072] The above lignocellulosic powder is one or more powders of rice husk powder, peanut shell powder, straw powder, corncob powder, plant stem and leaf powder, wood sawdust, ...

Embodiment 3

[0092] An environment-friendly single-layer micro-foamed PVC wood-plastic composite board, the mass ratio of each component in the raw material formula used is as follows:

[0093] Recycled polyvinyl chloride 41.2%, polyvinyl chloride resin 28.5%, wood fiber powder 7%, filler 8.9%, foam regulator 4.4%, composite stabilizer 1.5%, foaming agent 0.85%, reinforcing agent 2%, Impact modifier 2.25%, lubricant 0.3%, coupling agent 0.1% and anti-aging agent 3%.

[0094] In this embodiment, the above polyvinyl chloride recycled materials are PVC door and window powder, PVC pipe powder, PVC trademark paper powder, PVC floor powder, PVC film powder, PVC decorative board powder, PVC building formwork powder One or more of them, and the powder particle size of the polyvinyl chloride recycled material is 40 mesh.

[0095] The above lignocellulosic powder is one or more powders of rice husk powder, peanut shell powder, straw powder, corncob powder, plant stem and leaf powder, wood sawdust, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com