Full-automatic tension testing machine

A tensile testing machine, fully automatic technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve problems such as low efficiency, achieve the effect of improving test efficiency and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

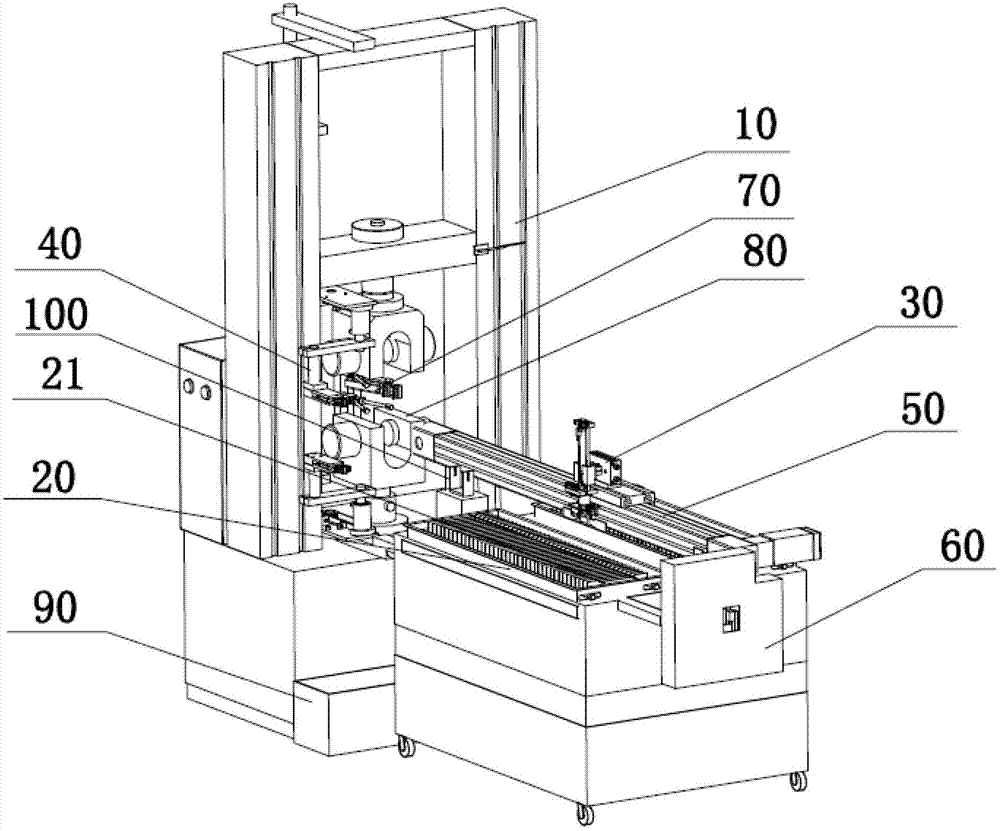

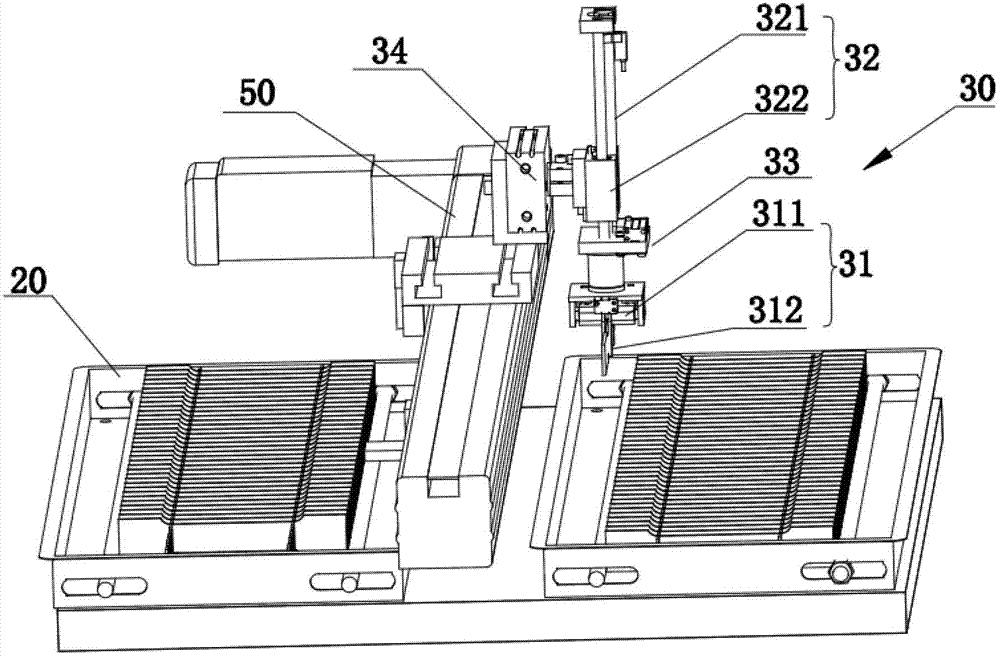

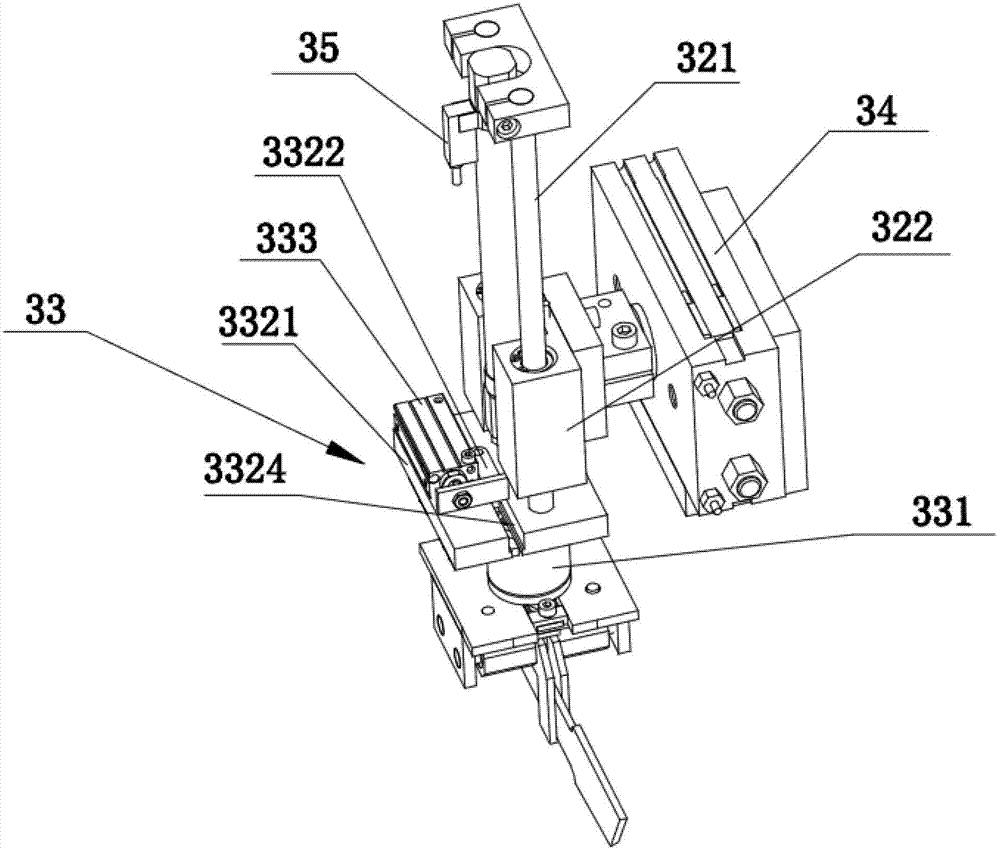

[0043] refer to figure 1 , propose an embodiment of the automatic tensile testing machine of the present invention. In the embodiment of the present invention, the fully automatic tensile testing machine includes a main machine 10, a lofting device 20, a feeding manipulator 30, a feeding manipulator 40, a pushing mechanism 50, a cross-section measuring platform 60, a fully automatic extensometer 70, and a hydraulic horizontal pushing fixture 80 And recovery device 90. The lofting device 20 is provided with a lofting tray 21 for placing samples, and the feeding manipulator 30 is used to clamp the samples and transfer the samples to the cross-section measuring platform 60 by the push mechanism 50 for measurement or transfer To the hydraulic horizontal push fixture 80, the host machine 10 is used to stretch the sample ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com