High-temperature creep fatigue test system

A fatigue test and high temperature creep technology, applied in the field of high temperature creep fatigue test system, can solve the problem of lack of test system, and achieve the effect of high measurement accuracy and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

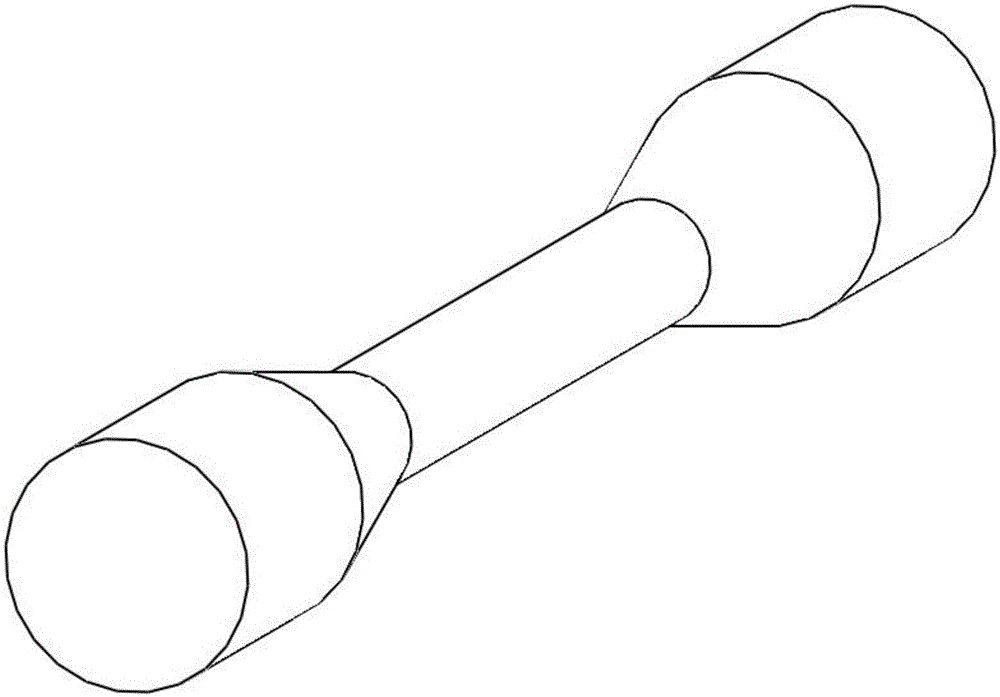

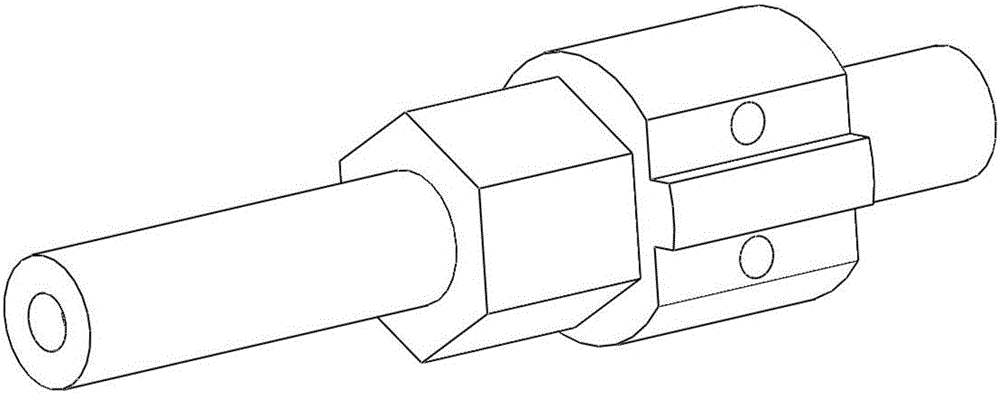

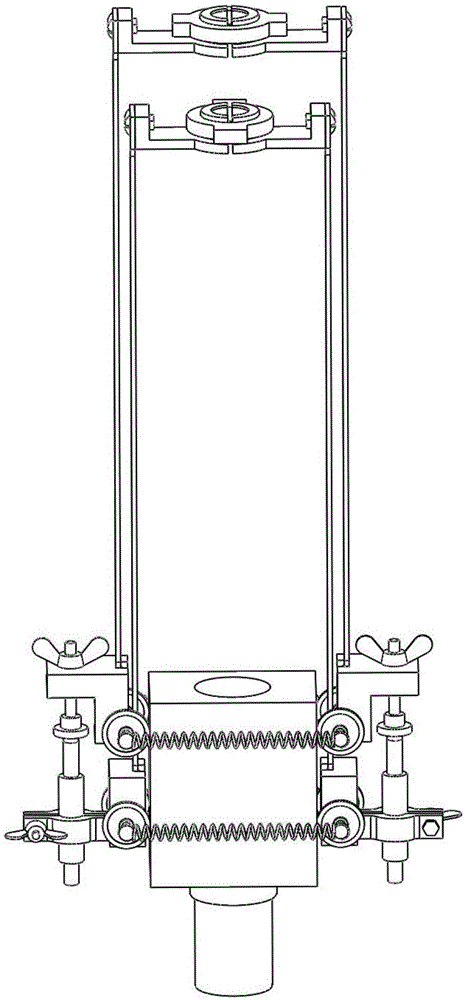

[0023] Specific implementation mode one: combine Figure 1 to Figure 7 Specific embodiments of the present invention will be described. A high-temperature creep fatigue test system of the present invention is composed of a fatigue testing machine 1, a sample fixture 2, a high-temperature furnace 3, a sample 4, a high-temperature extensometer 5, a cooling machine 6 and a main control computer. exist Figure 7 Among them, the upper and lower sample fixtures 2 are connected to the sample 4 through threads, which can ensure uniform axial loading of the sample 4; the sample fixture 2 is connected to the fatigue testing machine 1; the high-temperature extensometer 5 is connected to the sample through claws; After the high temperature furnace 3 installed on the fatigue testing machine 1 is moved to the corresponding position, the sample 4 is wrapped inside; the cooling machine 6 is connected with the upper and lower sample fixtures 2 through the inlet and outlet pipes respectively; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com