High-precision ultrahigh temperature video extensometer and measurement method thereof

A video extensometer and ultra-high temperature technology, which is applied in measurement devices, instruments, optical devices, etc., can solve the problems of inability to meet real-time high-precision strain measurement requirements and fast calculation speed, so as to improve the accuracy of strain measurement and expand the applicable temperature. Scope, clear imaging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

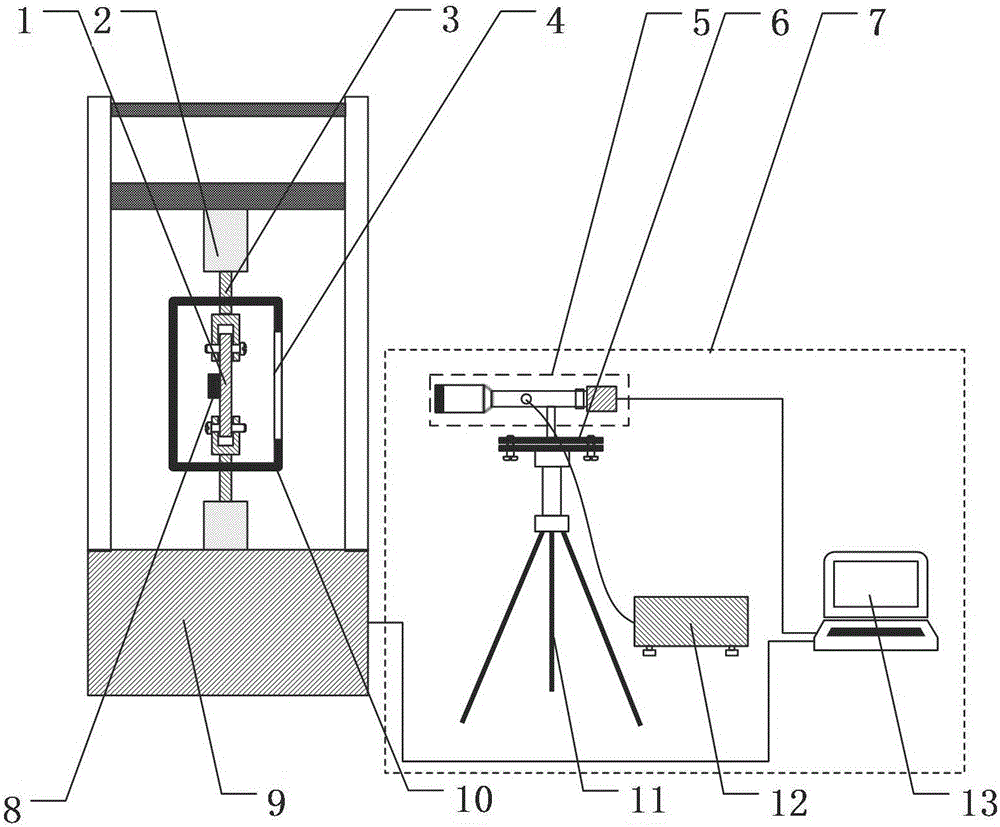

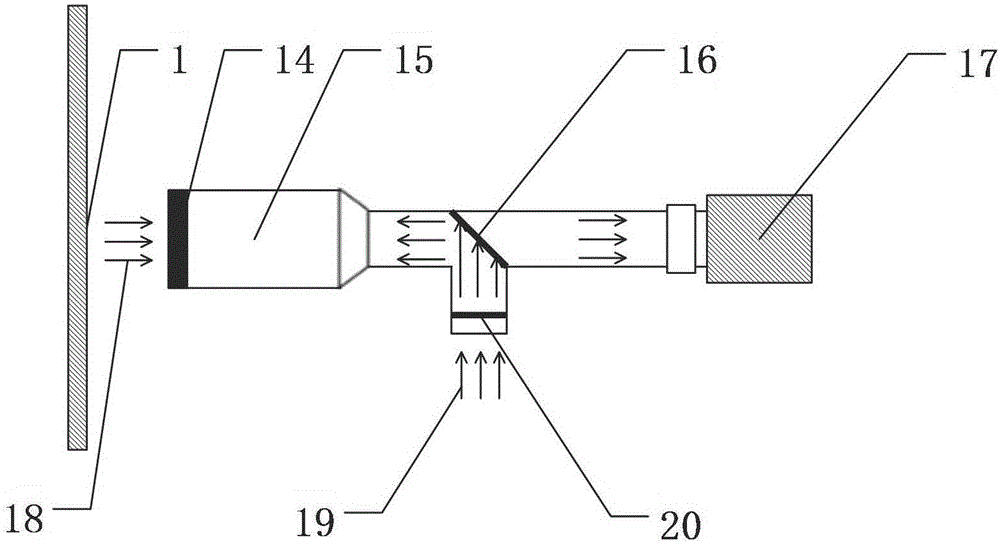

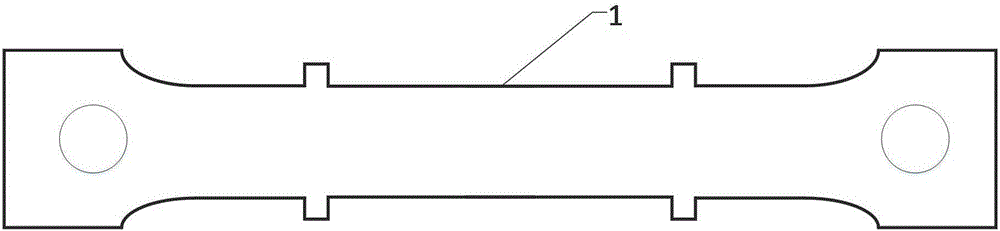

[0035] A high-precision ultra-high temperature video extensometer, including: a coaxial telecentric imaging system 5, a mechanical support adjustment platform 6, a monochromatic light source 12, a narrow bandpass filter 14 corresponding to the wavelength of the monochromatic light source, an ultraviolet camera, and a tripod 11. Computer 13; the coaxial telecentric imaging system 5 is used to collect clear images of the image surface through the optical quartz glass observation window under ultra-high temperature conditions; the mechanical support adjustment platform 6 is used to support the coaxial telecentric imaging system 5, By adjusting the mechanical support adjustment platform 6, the adjustment of three directions in space and six degrees of freedom in three angles can be realized, thereby adjusting the optical axis of the coaxial telecentric imaging system 5 to be perpendicular to the region of interest on the surface of the test piece 1, and obtaining High-definition an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com