Method for measuring pile shaft internal force and cross section displacement in vertical dead-load test of foundation pile

A technology of vertical displacement and pile body, which is applied in the direction of measuring force, foundation structure test, measuring device, etc. It can solve the problems that the strain distribution can only be inferred, the sensor, the connecting wire is damaged, and cannot be reused.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

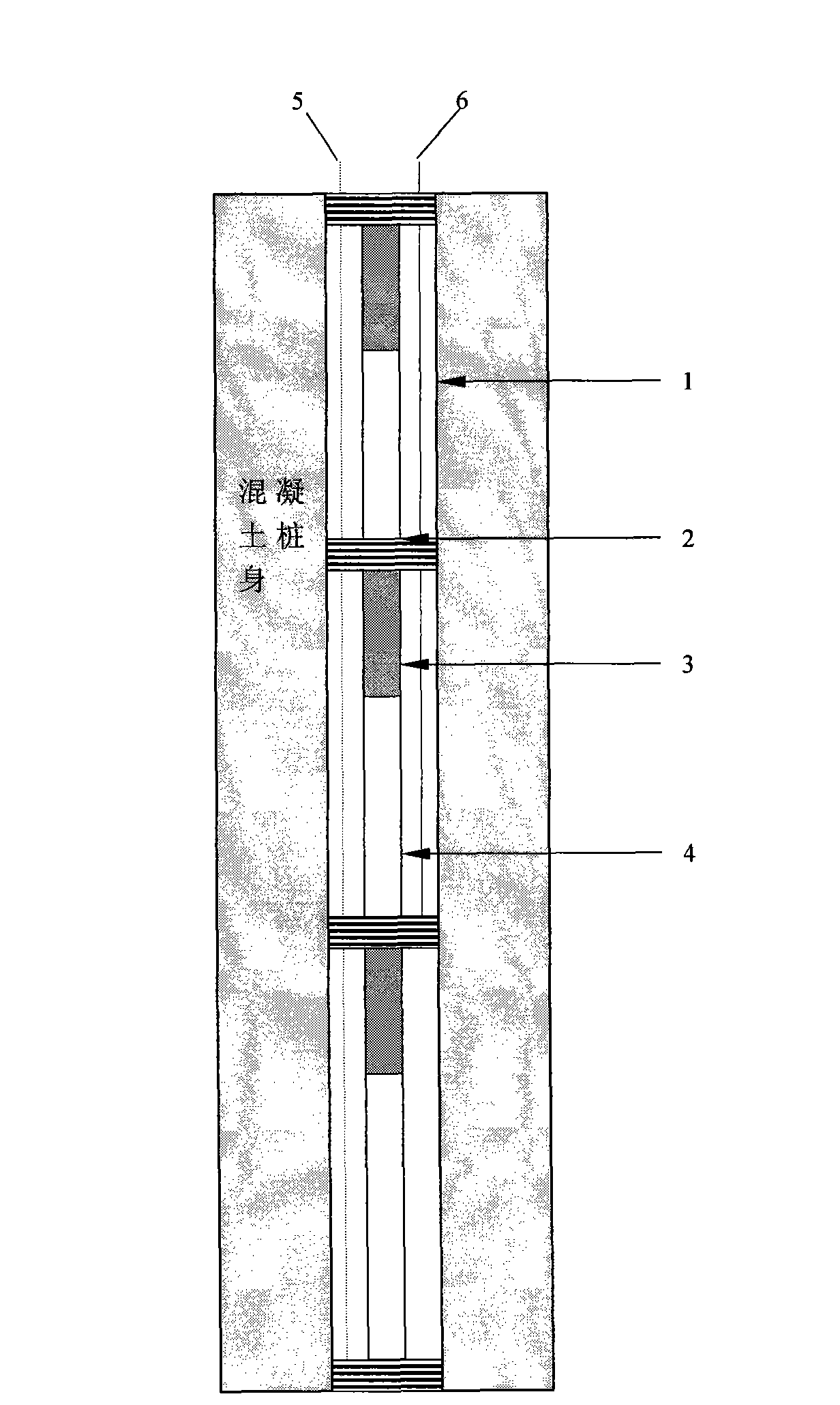

[0022] The concrete steps of the inventive method are:

[0023] (1) When the pile is made, the casing 1 is buried or the hole 1 is directly drilled in the pile body after the construction of the foundation pile is completed. Casing material or drilling tools are not limited, but it is required that the axis of casing 1 or borehole 1 should be parallel to the longitudinal axis of the pile body, and the size of casing 1 or borehole 1 should match the selected anchor head 2; 1 or the number of boreholes 1 in the pile body is not limited, and should be arranged symmetrically along the central axis of the cross section.

[0024] (2) Set the number of anchor heads and the location of the buried section according to the geotechnical engineering investigation report of the site where the test pile is located, pile formation or pile driving records, regional experience and design requirements, etc. The anchor head 2 can generally be buried at the interface of two different soil layers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com