Non-contact type strain measurement method based on visual discrimination

A non-contact, strain measurement technology, applied in measuring devices, image data processing, instruments, etc., can solve the problems of inability to measure the tensile properties of micro-devices and easily damaged test pieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

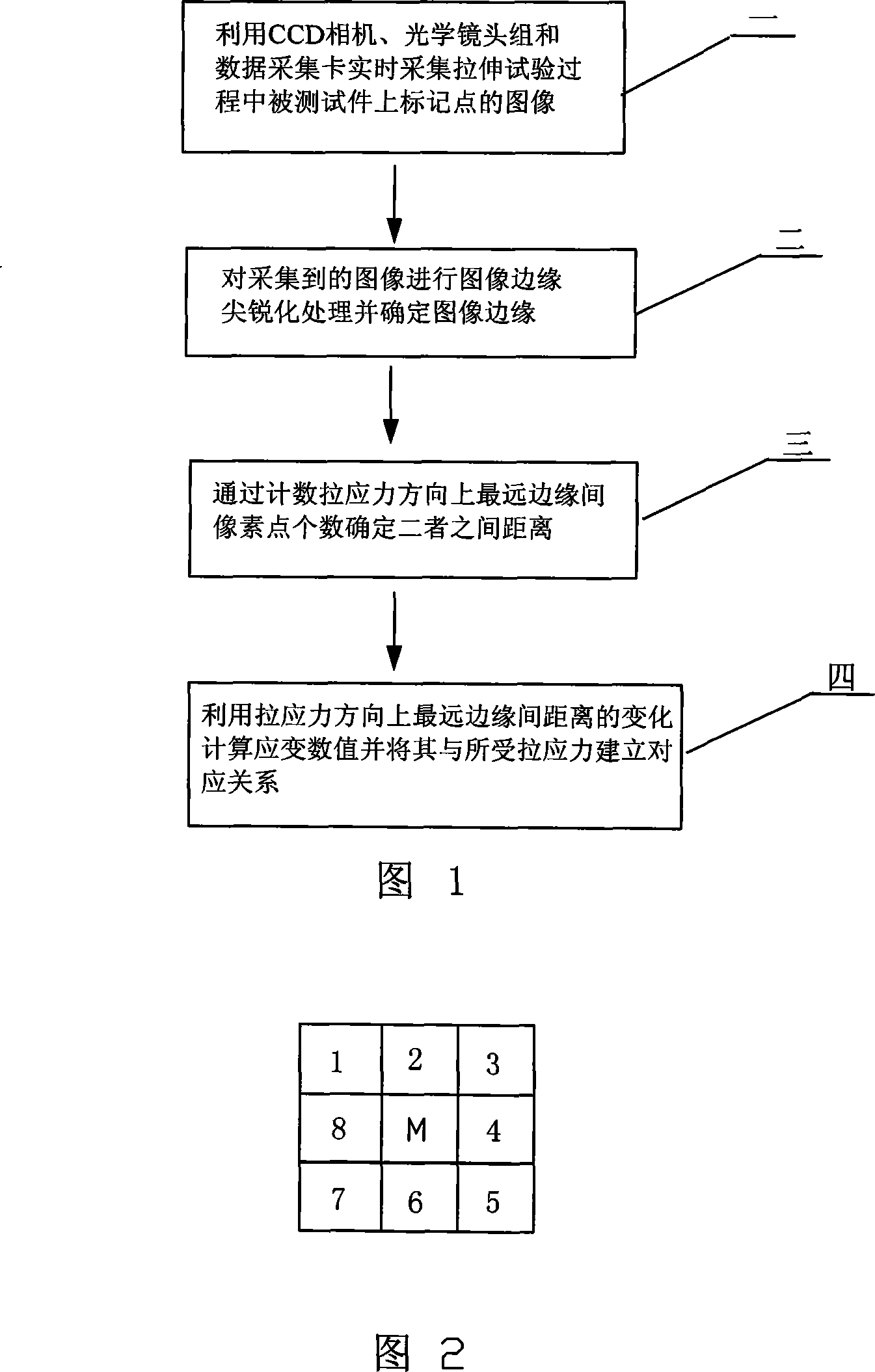

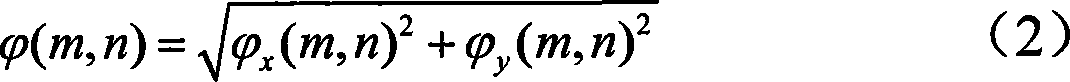

[0007] Specific Embodiment 1: The present embodiment will be specifically described below with reference to FIG. 1 . This embodiment consists of the following steps: 1. Using a CCD camera, an optical lens group and a data acquisition card to collect in real time the images of the marked points on the test piece during the tensile test; 2. Sharpening the edges of the collected images Process and determine the edge of the image; 3. Determine the distance between the two by counting the number of pixels between the farthest edges in the direction of tensile stress; 4. Calculate the strain value using the change in the distance between the farthest edges in the direction of tensile stress and compare it with The corresponding relationship is established for the tensile stress.

[0008] The CCD camera adopts MTV-1881EX black and white industrial camera, and the data acquisition card is a PCI image acquisition card of the OK-M10A model. The optical lens group is placed in front of ...

specific Embodiment approach 2

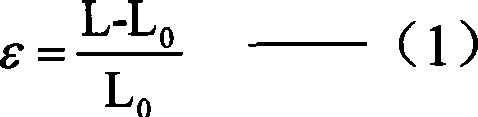

[0010] Specific embodiment two: the difference between this embodiment and embodiment one is: step two of embodiment one is made up of the following steps: A, use Gaussian filter to carry out smooth processing to the image that comes in, to suppress the interference of noise; B. Calculate the gradient magnitude and direction of each pixel of the smoothed image, and highlight the points with significant gradient magnitude changes, thereby enhancing the edge display of the image. The specific process is as follows: use the formula (2) to calculate the gradient magnitude and direction of each pixel of the smoothed image,

[0011]

[0012]

[0013] Formulas (2) and (3) are used to calculate the gradient magnitude and direction, x (m, n) is the gradient in the x direction, y (m, n) Gradient in the y direction, (m, n) is the gradient magnitude, θ(m, n) is the gradient direction, and the points with significant changes in the gradient magnitude are highlighted, that is, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com