Uni-directional stretching test clamp for warm shaping of metal plate

A technology of warm forming and uniaxial stretching, which is applied in the direction of analyzing materials, using stable tension/pressure to test material strength, measuring devices, etc. cumbersome and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] specific implementation plan

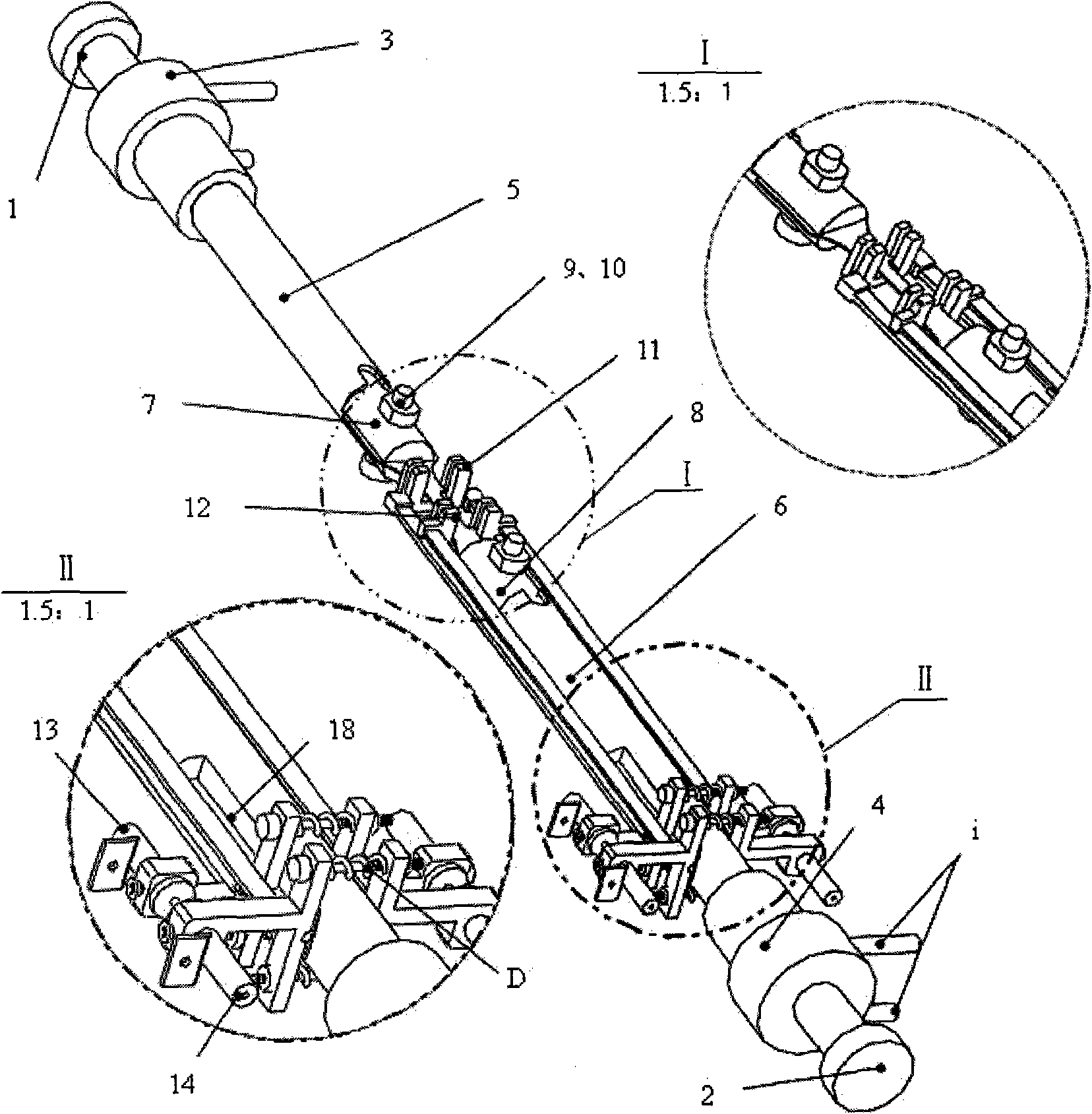

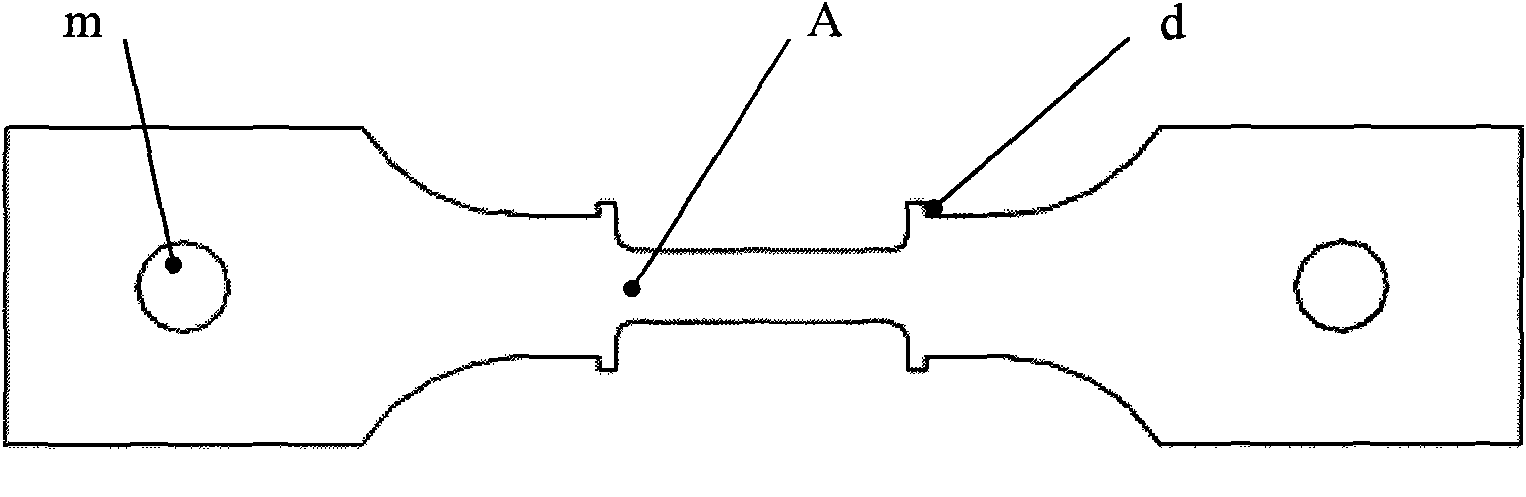

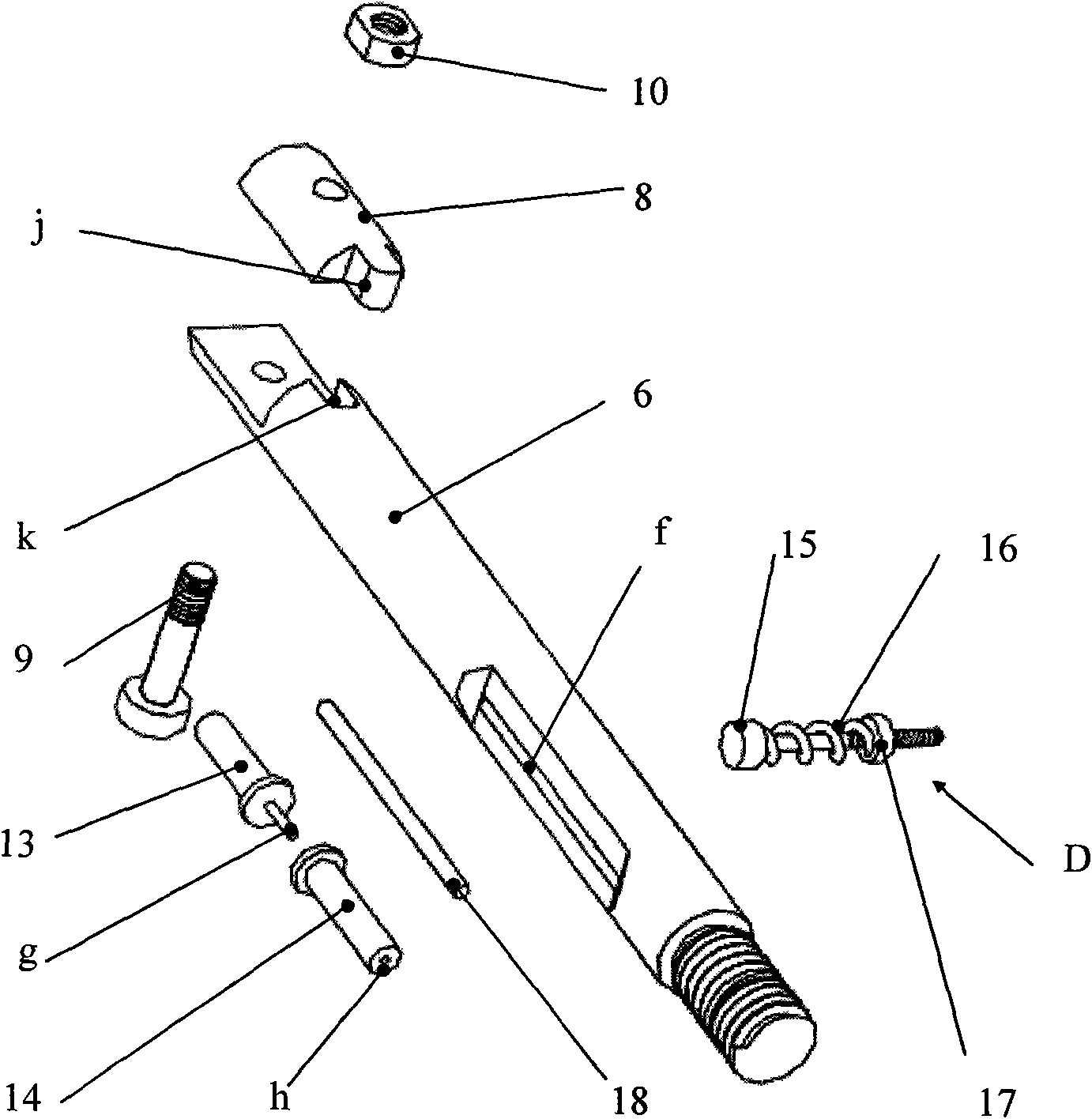

[0025] The fixture is composed of a displacement lead-out part, a tensile test piece positioning and clamping part, and a testing machine connection part. This fixture can lead the gauge length displacement of tensile test pieces with different softening degrees at different temperatures out of the heating furnace, which is convenient to use the extensometer to accurately measure the displacement; after the tensile test pieces are clamped, the direction of the loading force of the testing machine can be guaranteed The length direction of the tensile test piece is collinear; there is a cooling device at the connection with the testing machine, which can cool the connection between the fixture and the testing machine under high temperature conditions.

[0026] The displacement lead-out part of the fixture is composed of an upper displacement lead-out rod 11, a lower displacement lead-out rod 12, an upper cylindrical sleeve 13, a lower cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com