Device for testing fatigue crack growth rate of metal material in aqueous corrosive medium

A fatigue crack propagation and metal material technology, applied in the field of metal fatigue crack growth rate test devices, can solve problems such as difficulty in accurately observing crack length, and achieve the effect of reducing labor intensity and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

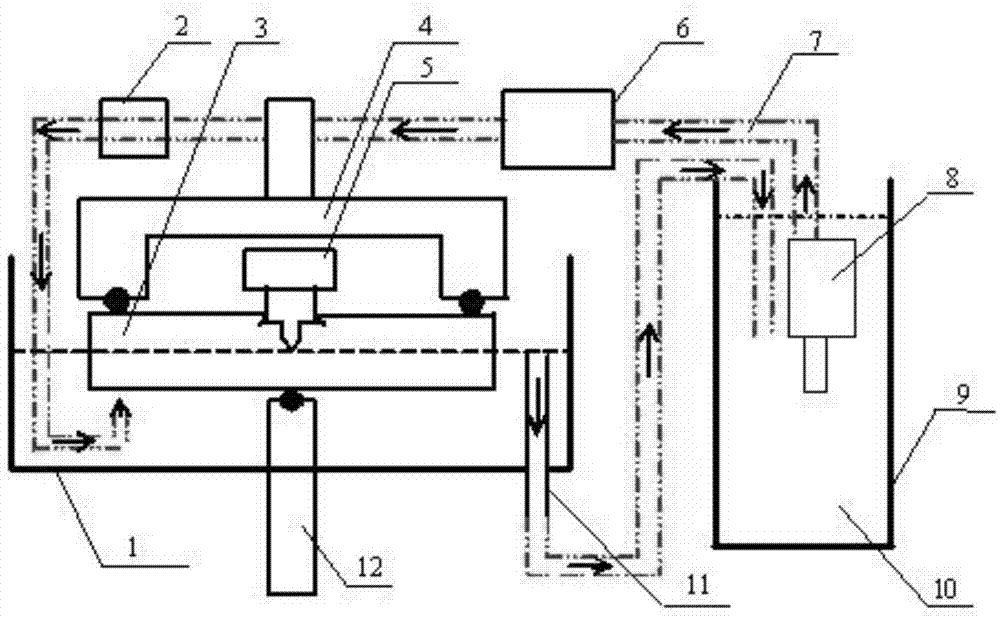

[0018] The present invention is described in more detail below in conjunction with accompanying drawing example:

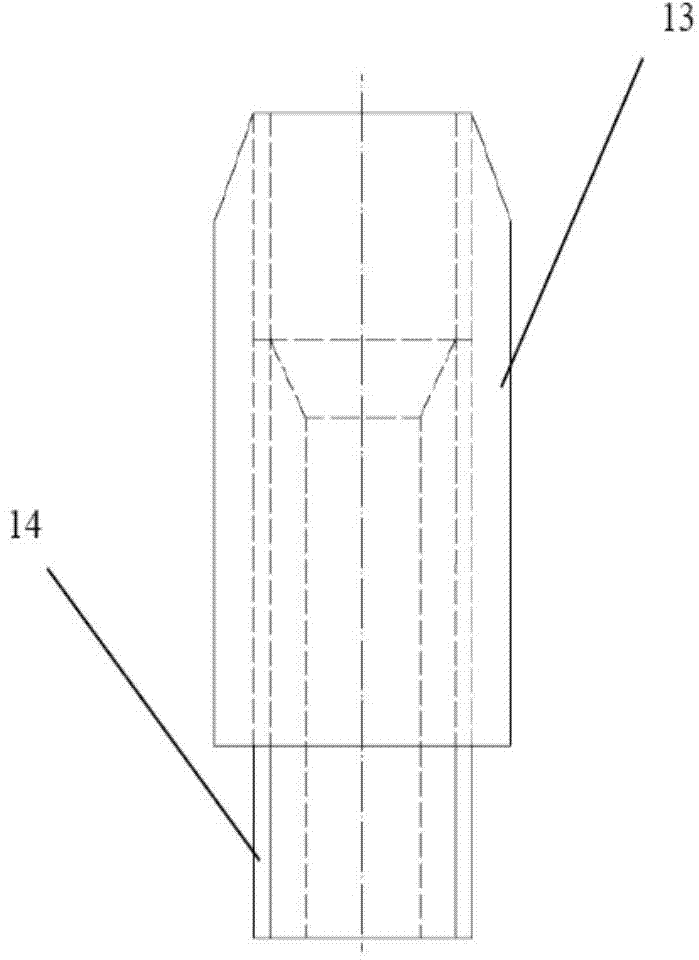

[0019] combine Figure 1~2 , the test device of the metal material fatigue crack growth rate in the aqueous corrosive medium adopts a single-side notch three-point bending (SEB) test piece, and an integral knife edge is designed on the test piece, and the knife edge of the test piece is upward, so that the extensometer is just above the test piece.

[0020] According to the installation method of the specimen, the corrosion solution circulation system was designed so that the specimen below the crack tip was completely immersed in the corrosion solution. It is characterized in that it includes a test container 1, a lower pressure head 12 and an overflow pipe 11 installed on the test container 1, a temperature controller 2, a rust filtering device 6 and a water pump 8 are connected through a hose 7, and the water pump 8 connects the The corrosive solution 10 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com