Novel composite material unnotched compression test fixture

A composite material and compression test technology, which is applied in the direction of analyzing materials, applying stable tension/pressure to test the strength of materials, measuring devices, etc., can solve the problems of difficulty in strain collection and low efficiency of non-notched compression tests, and improve test efficiency. , Improve efficiency and accuracy, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

[0040] Applied to the compression test of fiber-reinforced composite materials, it can solve related test problems such as strain measurement in a high-temperature environment, and the semi-open design makes the clamping of the test piece more efficient and accurate.

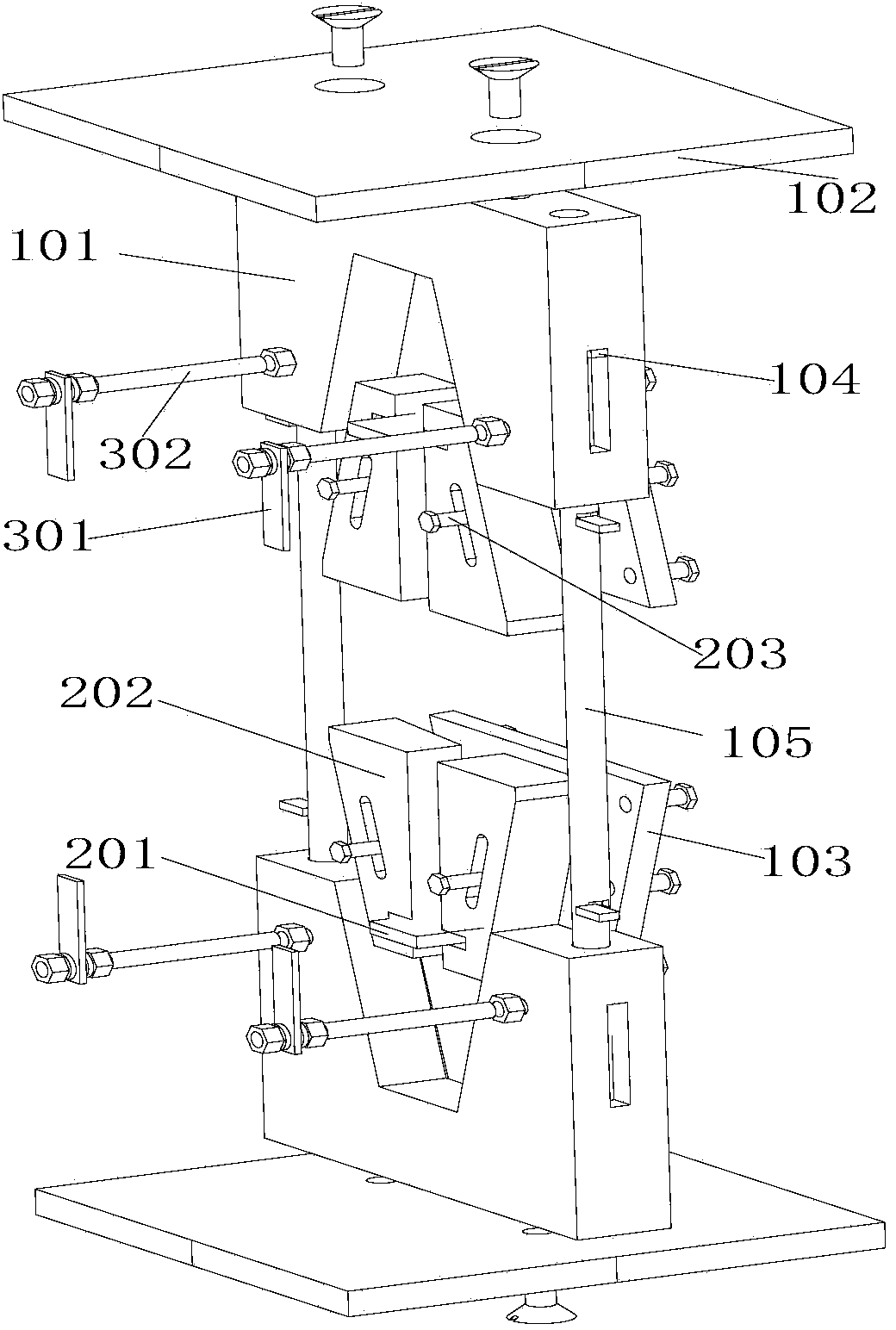

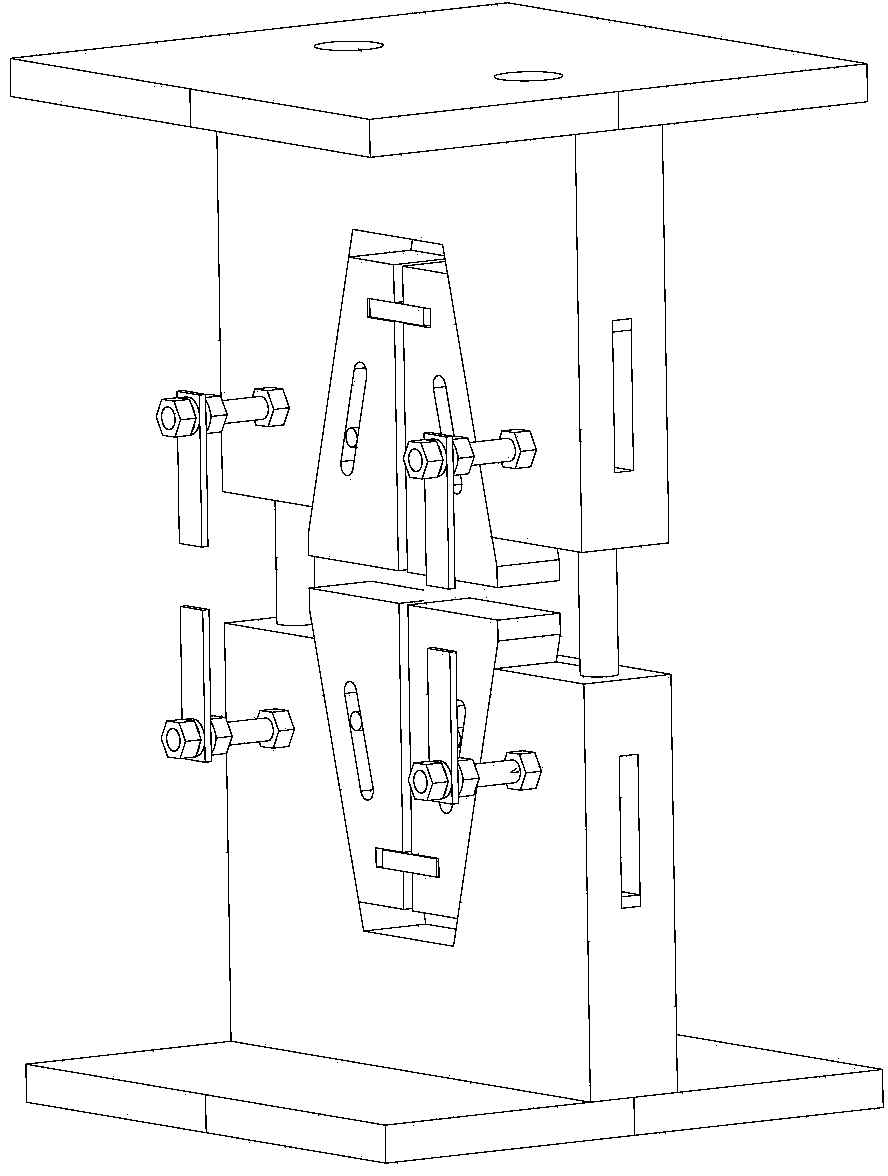

[0041] The present invention is a kind of novel composite material non-notched compression test jig, such as figure 1 and figure 2 As shown, it consists of a test loading module, a test clamping module and a strain measurement module.

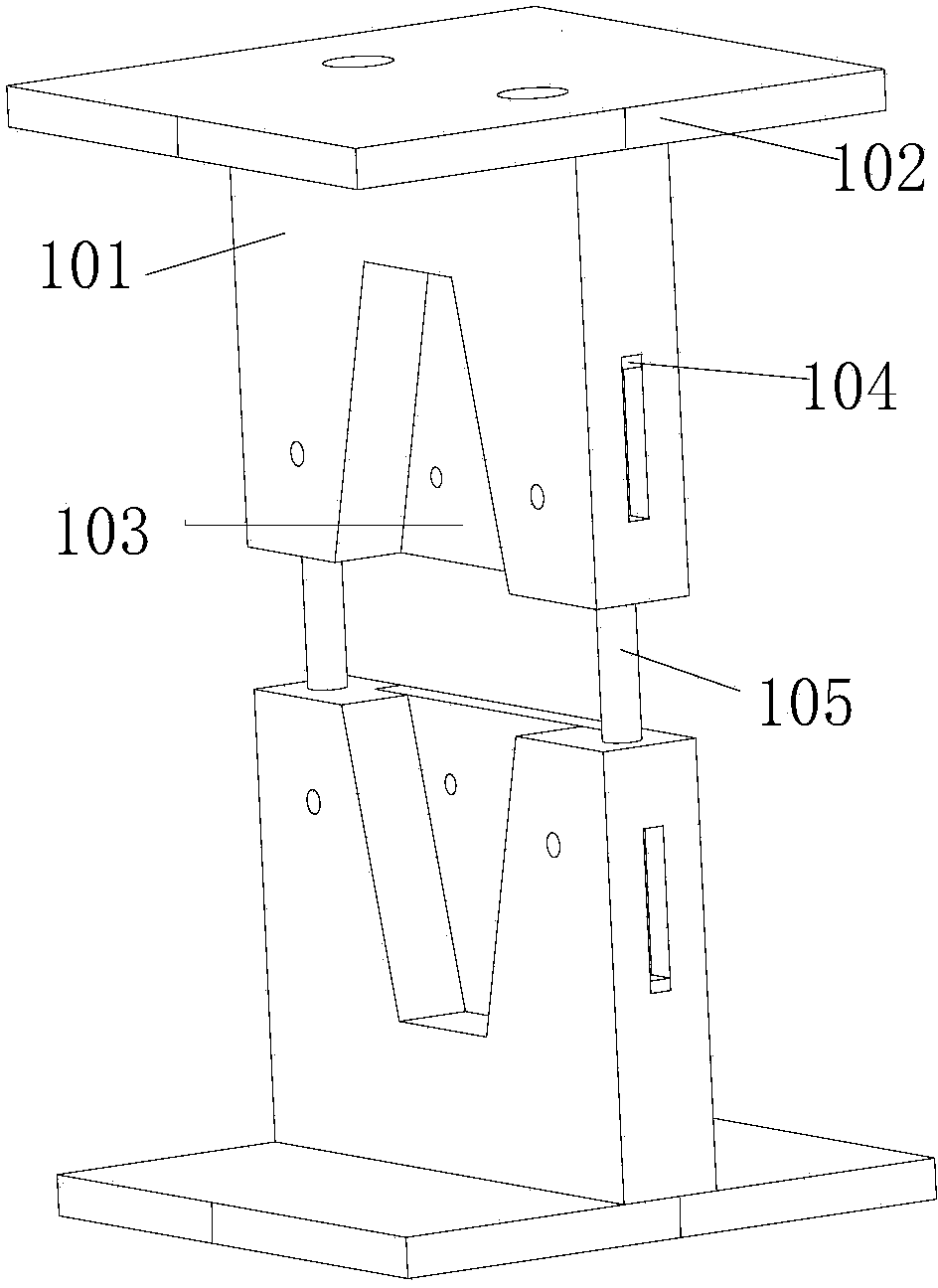

[0042] The test load modules such as 3 and Figure 4 Shown: including 2 sets of the same base 101 , end pressure plate 102 , clamp block cover 103 , guide shaft 105 and 4 stroke control keys 104 .

[0043] Such as Figure 8 As shown, the base 101 is a "concave" structure, and the bottom of the base 101 is processed with two screw holes, and the end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com