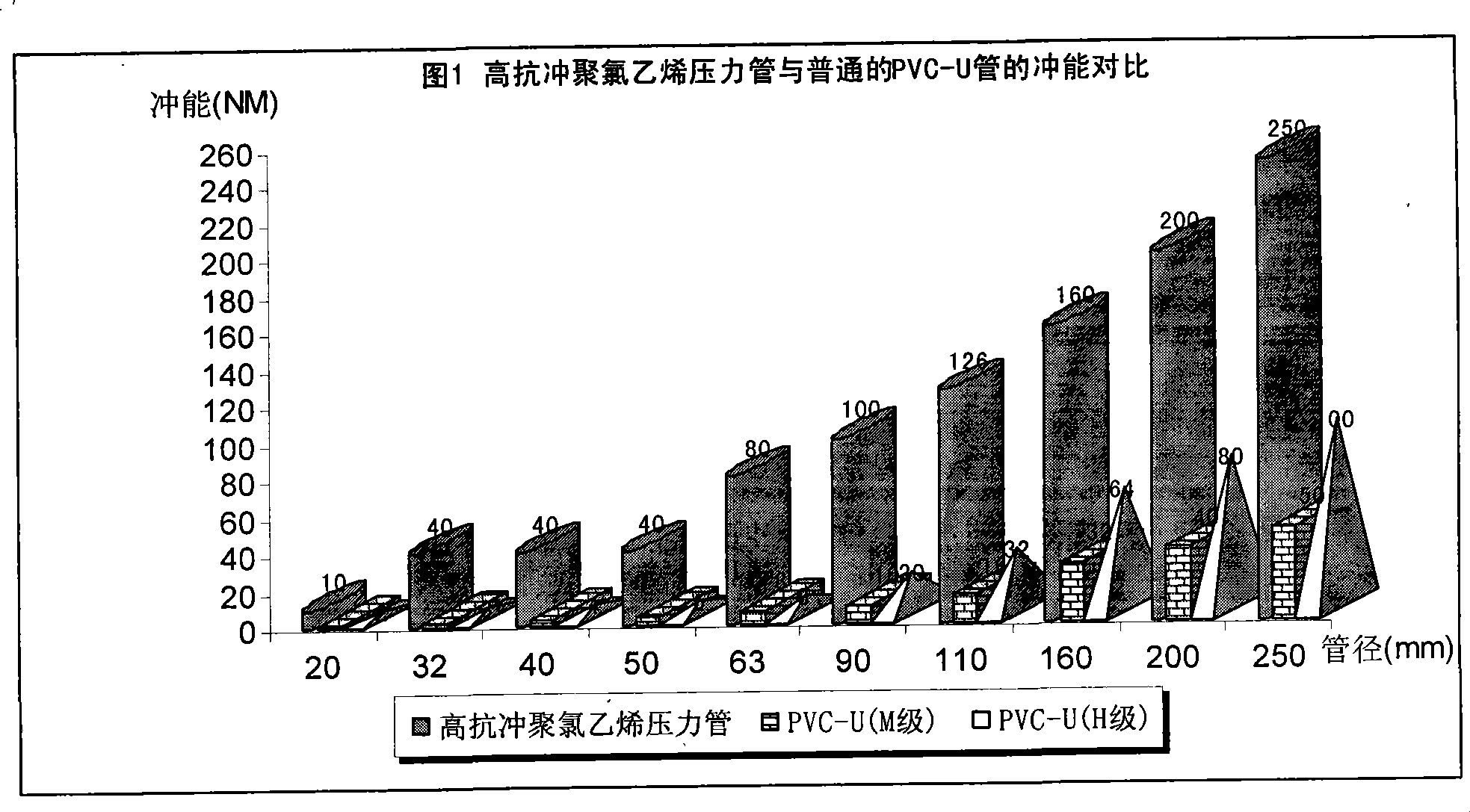

High impact polychloroethylene pressure tube

A technology of polyvinyl chloride and pressure pipes, applied in pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve problems such as poor impact resistance, easy leakage, easy pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] specific implementation plan

[0007] The invention provides a high-impact polyvinyl chloride pressure pipe, which uses the following materials: PVC resin, heat stabilizer, lubricant, impact modifier, filler, and colorant.

[0008] The PVC resin is SG-5 type resin.

[0009] The heat stabilizer is a rare earth calcium zinc composite stabilizer or a uracil organic stabilizer.

[0010] The lubricant is a mixture of two or more of polyethylene wax, paraffin wax and Fischer-Tropsch wax.

[0011] The impact modifier is a mixture of one or more of impact-resistant ACR, MBS or ABS and PMMA organic rigid particles.

[0012] The filler adopts nano calcium carbonate surface-treated with stearic acid.

[0013] The colorant is titanium dioxide.

[0014] 100 parts by weight of PVC resin, 1.5-4.0 parts of heat stabilizer, 0.4-1.2 parts of lubricant, 6-12 parts of impact modifier, 0-5 parts of filler, 2-3 parts of colorant, heat After mixing and cold mixing, it is made into pipes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com