Oil-gas transportation large-scale high-pressure pipe fittings steel as well as pipes, pipe fittings and welding materials produced thereby

A high-pressure pipe, oil and gas technology, applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., can solve the problems of high carbon content in steel, low impact toughness, poor welding performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Through theoretical analysis and research on the role of alloy elements in steel, strengthening principles, structural elements, and production process interactions, and through domestic and foreign investigations and research, the alloy composition design, smelting, rolling and heat treatment systems have been established.

[0012] 1. The composition range of steel for large-scale high-pressure pipe fittings for oil and gas transportation is: C≤0.12%, Si≤0.35%, Mn≤1.60%, P≤0.030%, S≤0.015%, Ni≤0.50%, Cr≤0.30%, Cu≤ 0.30%, Mo≤0.25%, Nb≤0.05%, V≤0.09%, Ti≤0.05%, Al≤0.060%, the rest is Fe,

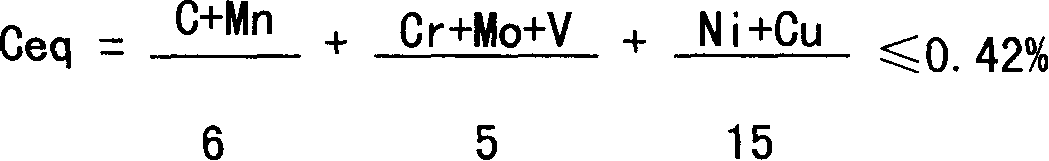

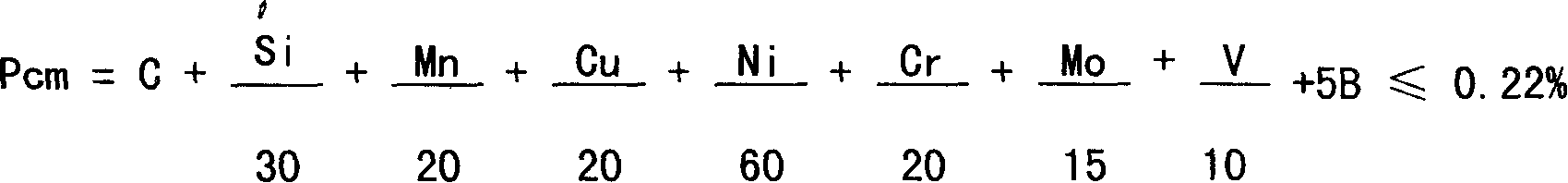

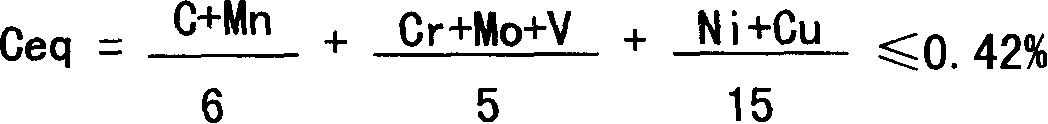

[0013] Ceq = C + Mn 6 + Cr + Mo + V 5 + Ni + Cu 15 ≤ 0.42...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com