Petroleum pipeline cleaning machine

A technology for oil pipelines and cleaning machines, applied in the direction of cleaning hollow objects, cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of high labor intensity, time-consuming and laborious, and low efficiency of manual cleaning of oil pipelines, so as to improve efficiency, The effect of expanding the cleaning range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments provided by the present invention are described in further detail in conjunction with the accompanying drawings:

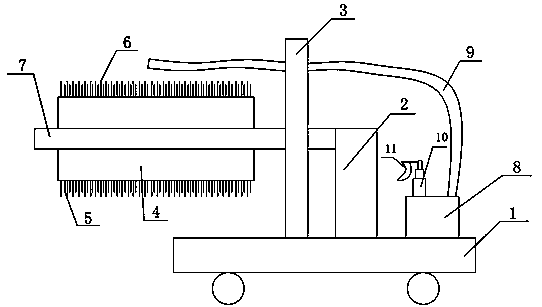

[0015] like figure 1 As shown, a pipeline cleaning machine includes a base 1, a cleaning brush 4, a rotating shaft 7, a motor 2, a vertical plate 3 and an air pressure container 8, and the vertical plate 3, the motor 2 and the air pressure container 8 are fixed on the base 1, and the The middle part of the vertical plate 3 is provided with a circular hole, a bearing is installed in the circular hole, the cleaning brush 4 is installed on the rotating shaft 7, and the rotating shaft 7 is connected with the output shaft of the motor 2 through the bearing, the The cleaning brush 4 is provided with soft bristles 6 and hard bristles 5 at intervals, and the bristles 5 are shorter than the soft bristles 6. The soft bristles 6 can remove the dust on the surface of the pipe wall, and then the hard bristles 5 can clean the pipe wall by moving the bottom pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com