Plugging cement slurry and igneous rock fracture developing well plugging method

A technology of cement slurry and cement, which is applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc., which can solve problems such as easy leakage and ineffective plugging by plugging technology, and achieve the effect of shortening construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

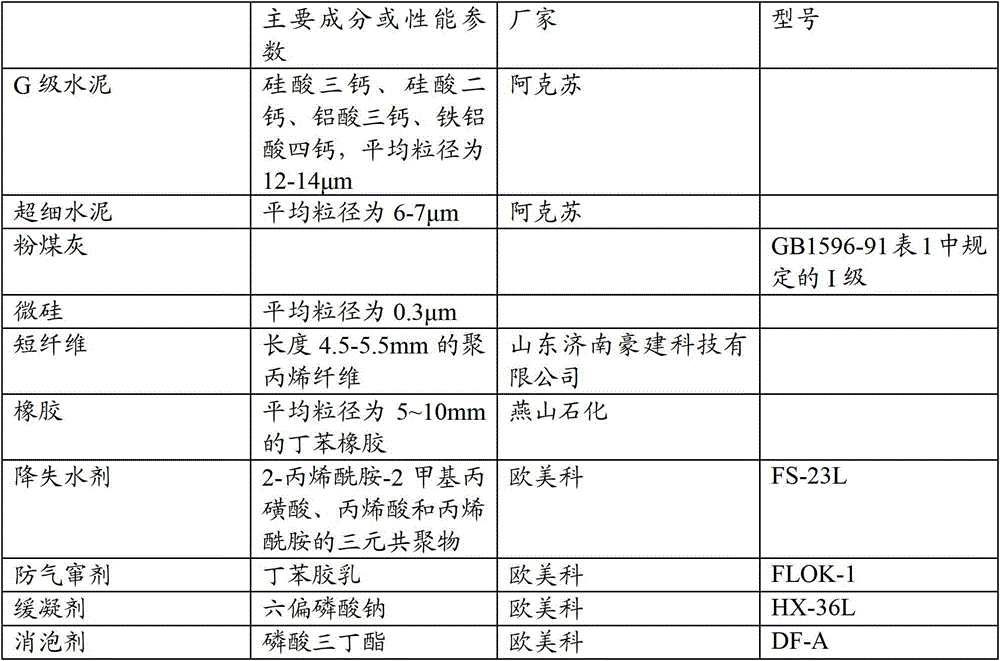

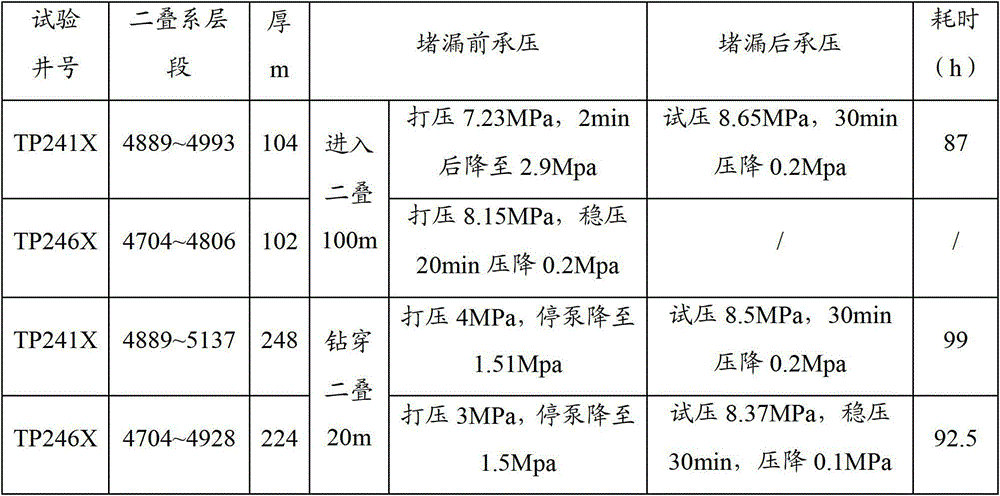

Method used

Image

Examples

Embodiment 1

[0066] Mix 100g of G-grade cement, 20g of ultra-fine cement, 45g of fly ash, and 10g of micro-silicon, then add 155.75g of water (water-solid ratio 89:100) and stir evenly to make a slurry mixture, and then mix according to the amount per liter of slurry mixture Add 6g of plugging agent, wherein the plugging agent includes: short fiber 0.116g, rubber 2.4g, fruit shell 1.28g and sawdust 2.4g, to obtain cement slurry.

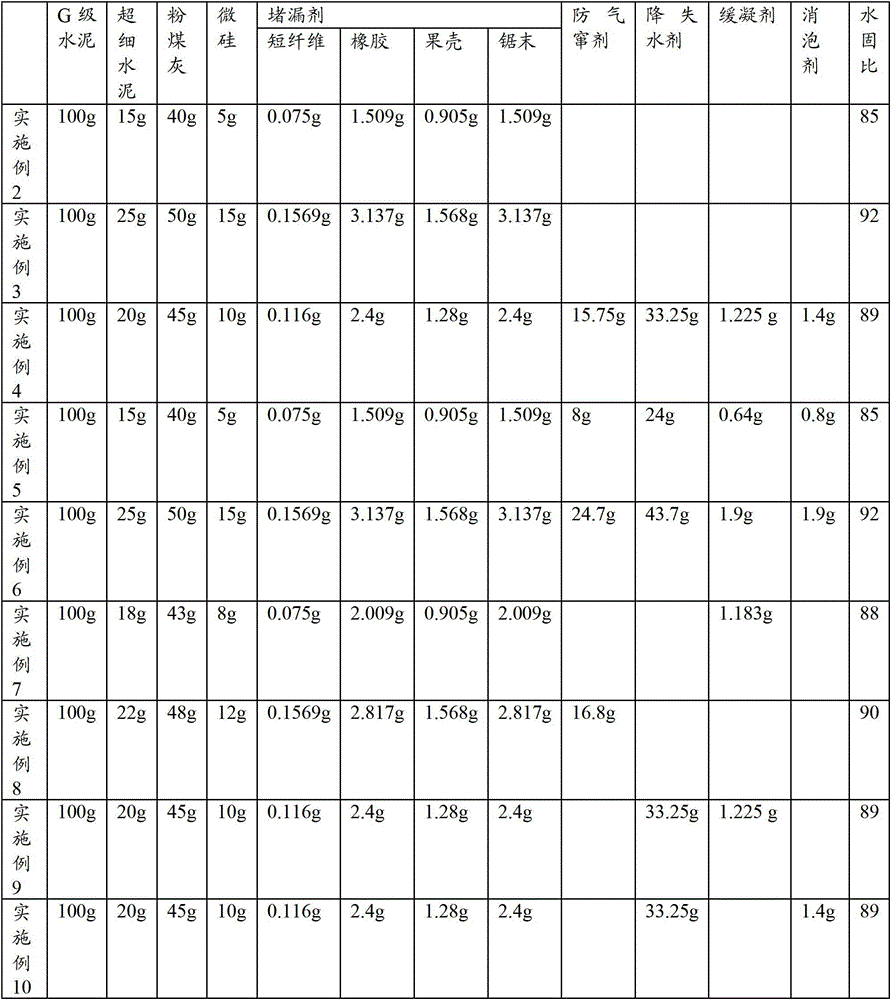

Embodiment 2-10

[0068] Embodiment 2-10 adopts substantially the same method as Embodiment 1, the difference lies in Table 2.

[0069] Table 2

[0070]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com