Device and method for simultaneously machining multiple holes

An integrated, workpiece clamping technology, used in metal processing equipment, manufacturing tools, boring/drilling, etc., can solve problems such as low standardization, high labor costs, and increased aperture, so as to improve work efficiency and improve processing efficiency. , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

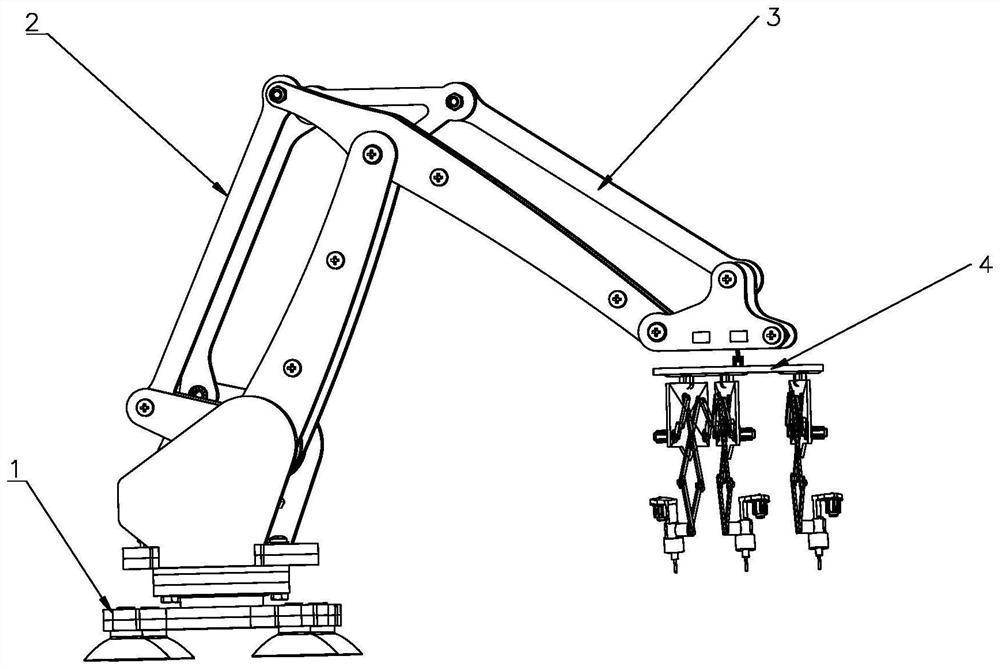

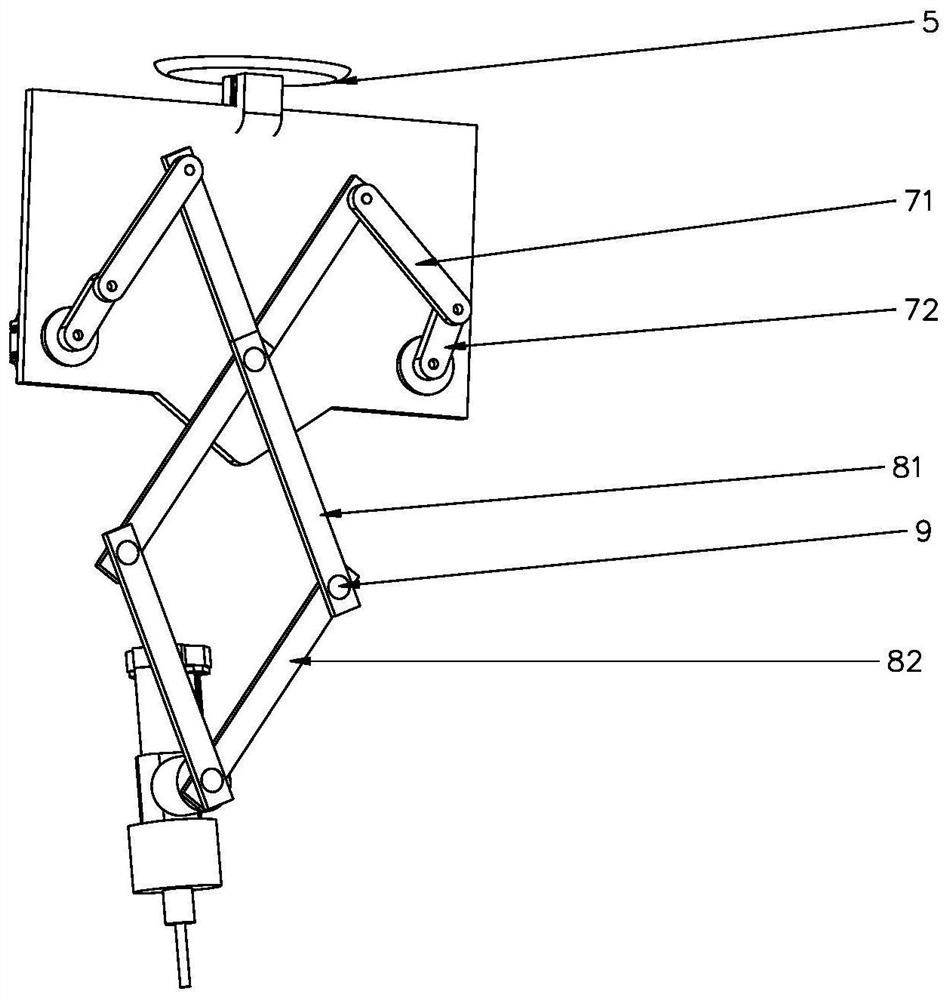

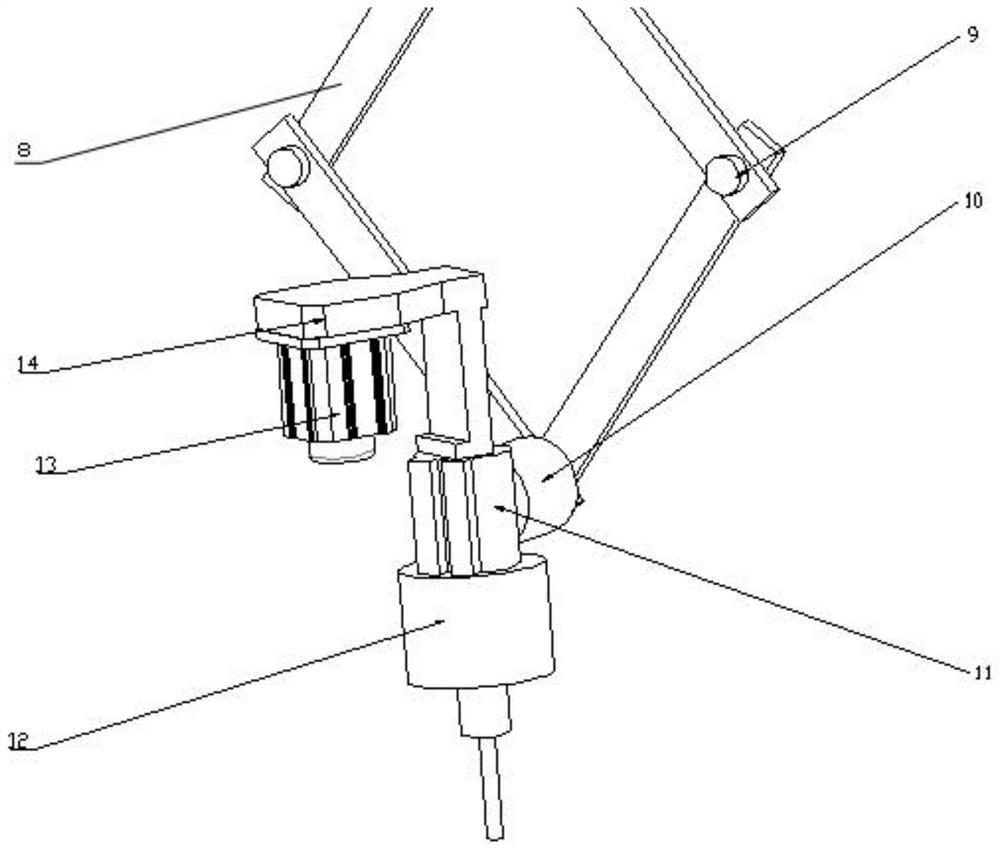

[0045] See Figure 1-Figure 6, a device for simultaneously processing holes, including a mechanical arm, a palm rest disc 4, a tool feed mechanism, a drilling and grinding integrated mechanism 11, a drill bit 15, and a profiling magnetic pole 16; the mechanical arm is a six-degree-of-freedom mechanical arm, and the actual production The six-degree-of-freedom robotic arm is refitted with ABB's IRB-6620 industrial robot, retaining its base 1, large arm 2, and small arm 3, and removing the execution end connected to the small arm 3: fingers and palms, and directly fixing the palm The supporting disc 4, that is, the execution end of the mechanical arm is fixed with a palm rest disc 4, on which a number of tool feed mechanisms are fixed, and a drillin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com