A curved glass drilling machine

A curved glass and drilling machine technology, which is applied to work accessories, manufacturing tools, grain processing, etc., can solve problems such as environmental pollution, collection of glass debris, and low processing accuracy, and achieve improved adsorption efficiency, improved stability, and reduced The effect of small vibrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

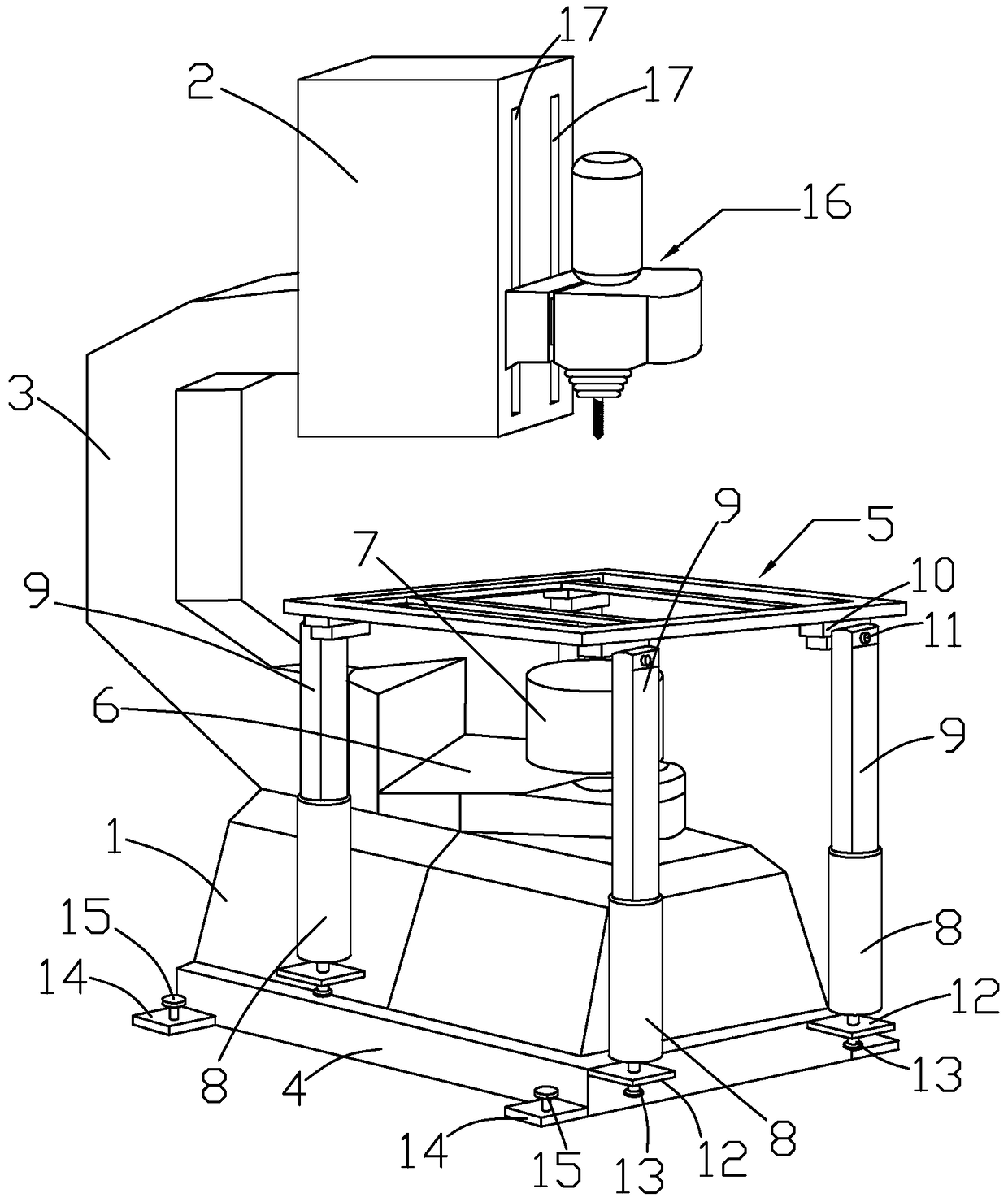

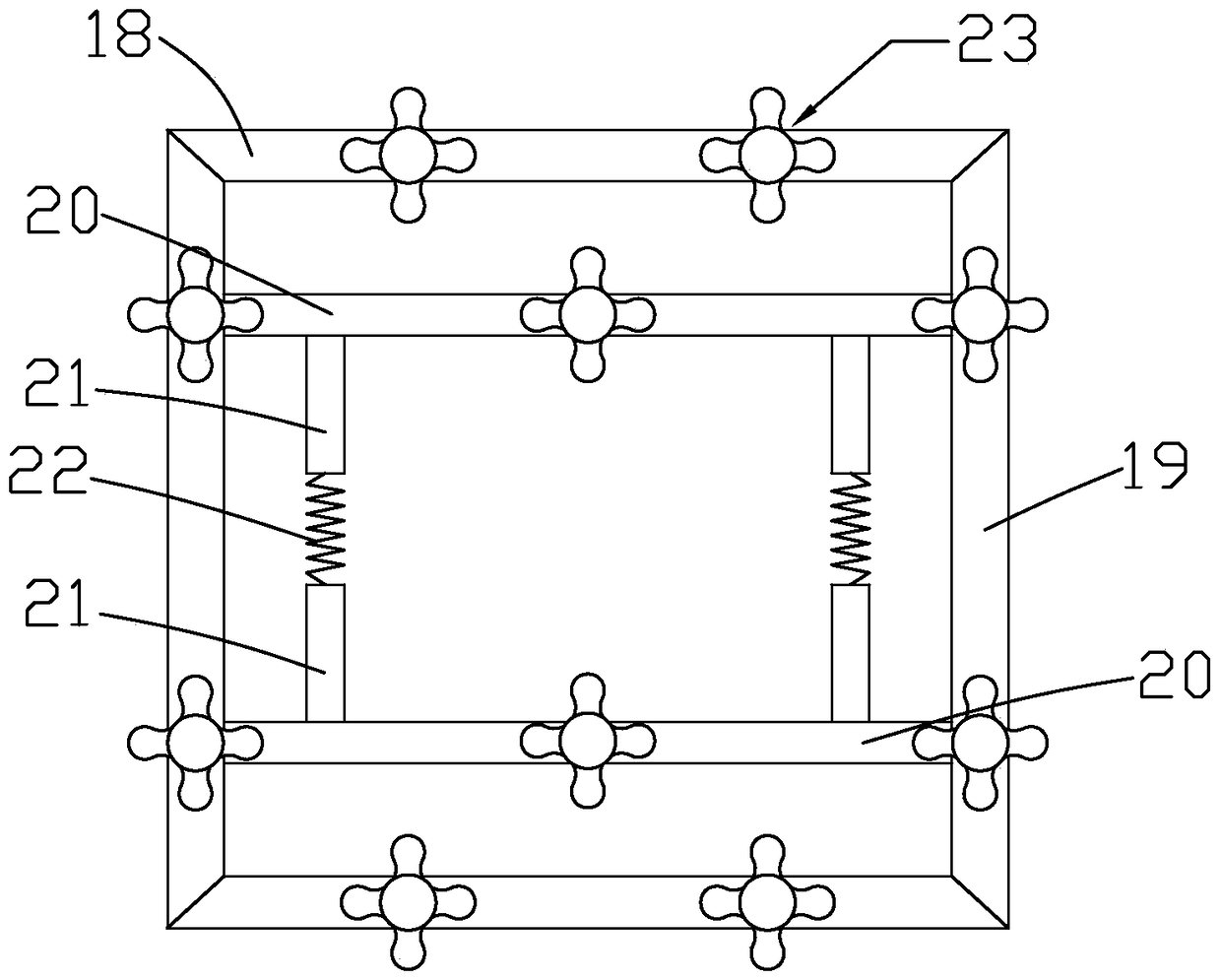

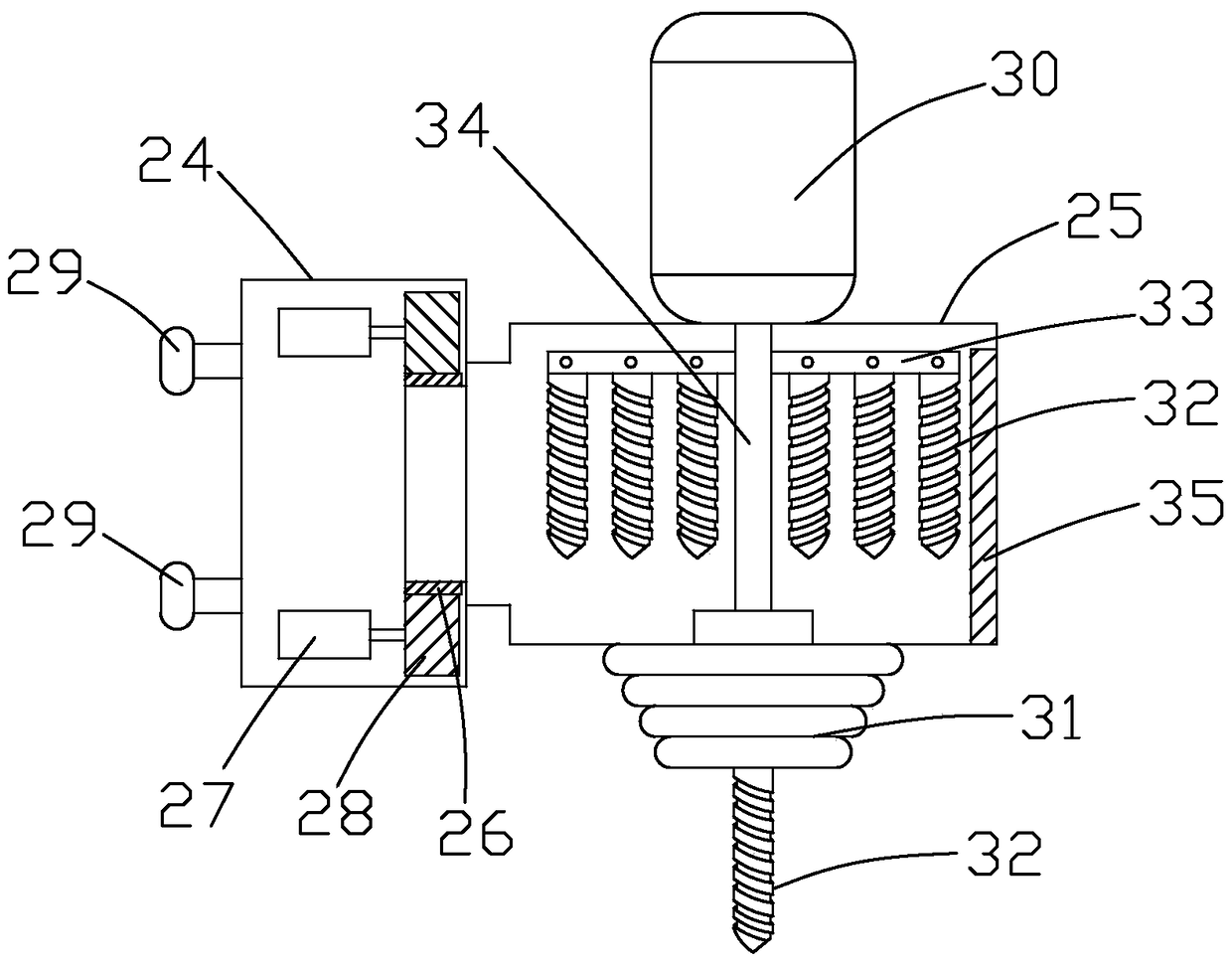

[0029] Such as Figure 1 to Figure 5 As shown, it is a curved glass drilling machine of the present invention. The drilling machine includes a cleaning box 1, a base 4, a drilling table 5 and a lifting power device 2. The base 4 is fixedly connected to the bottom surface of the cleaning box 1, and the cleaning box 1 A crushing box 45 is arranged inside, and two crushing rollers 46 are arranged in the crushing box 45, and a discharge pipe 47 is arranged at the bottom of the crushing box 45, and a collection hopper 48 is connected to the end of the discharge pipe 47, and a push block is arranged on the collection hopper 48. 49. The pulverizing box 45 can pulverize the absorbed bulk glass, which is convenient for collection and then processing and utilization.

[0030]The top surface of cleaning box 1 is provided with shock absorber 6, and shock absorber 6 can effectively reduce the vibration that suction device 7 brings, reduces the noise of drilling machine when working, prolon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com