Method and apparatus for sealing abandoned oil and gas wells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

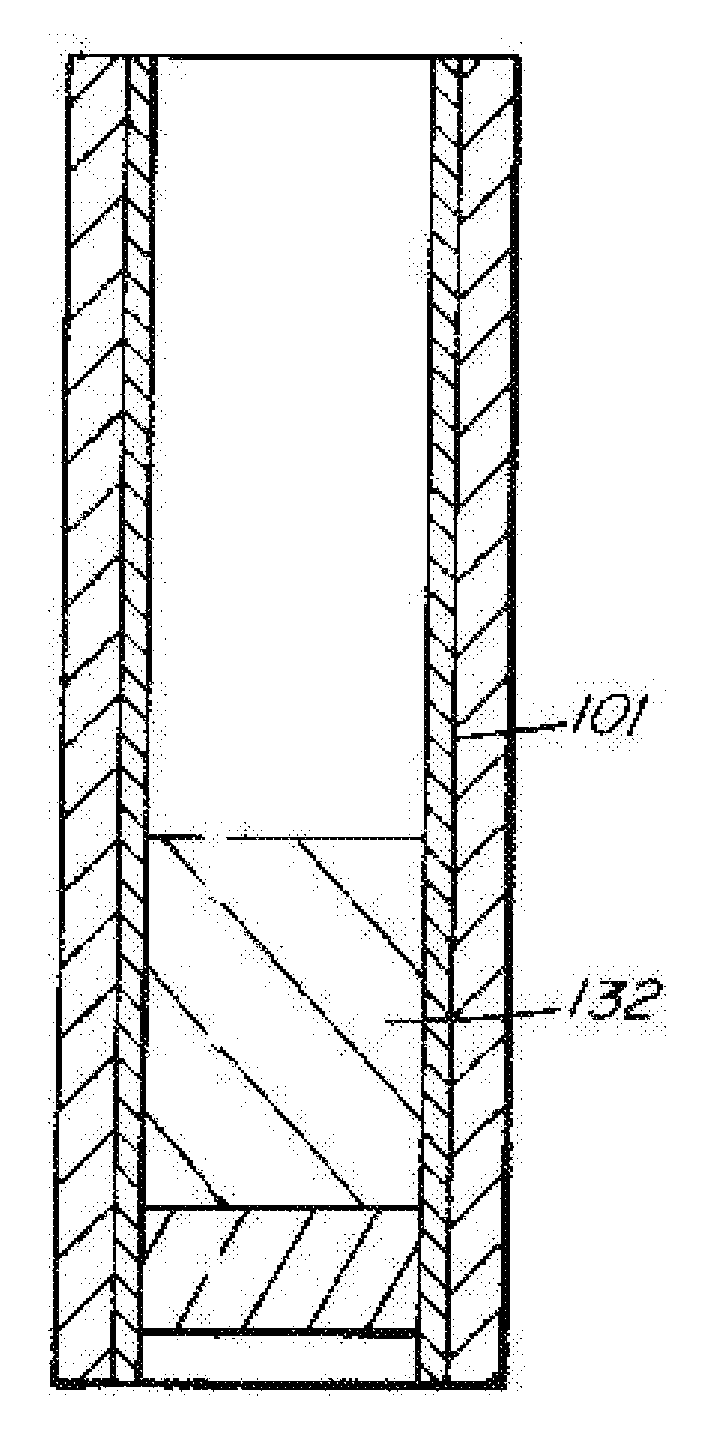

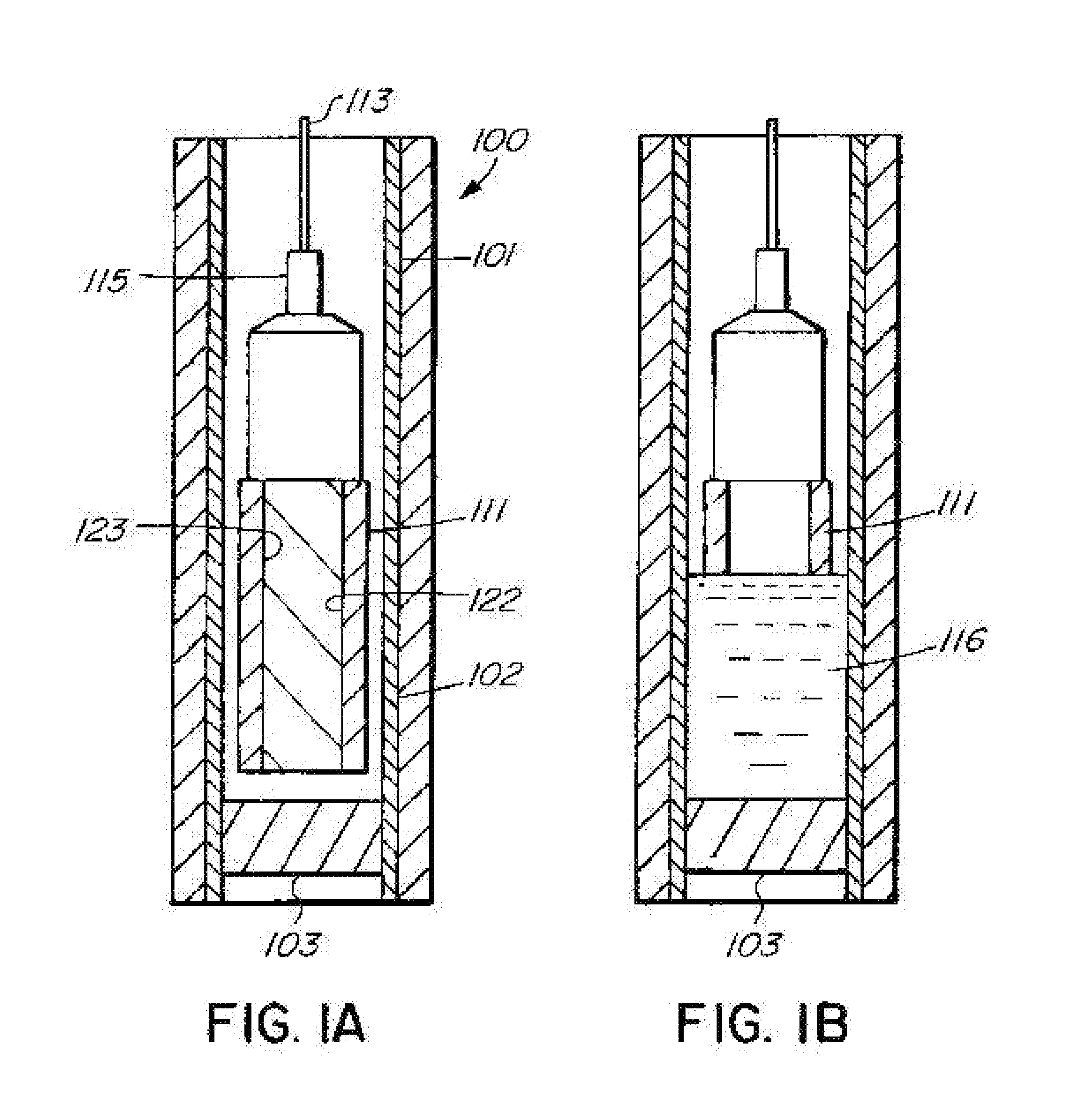

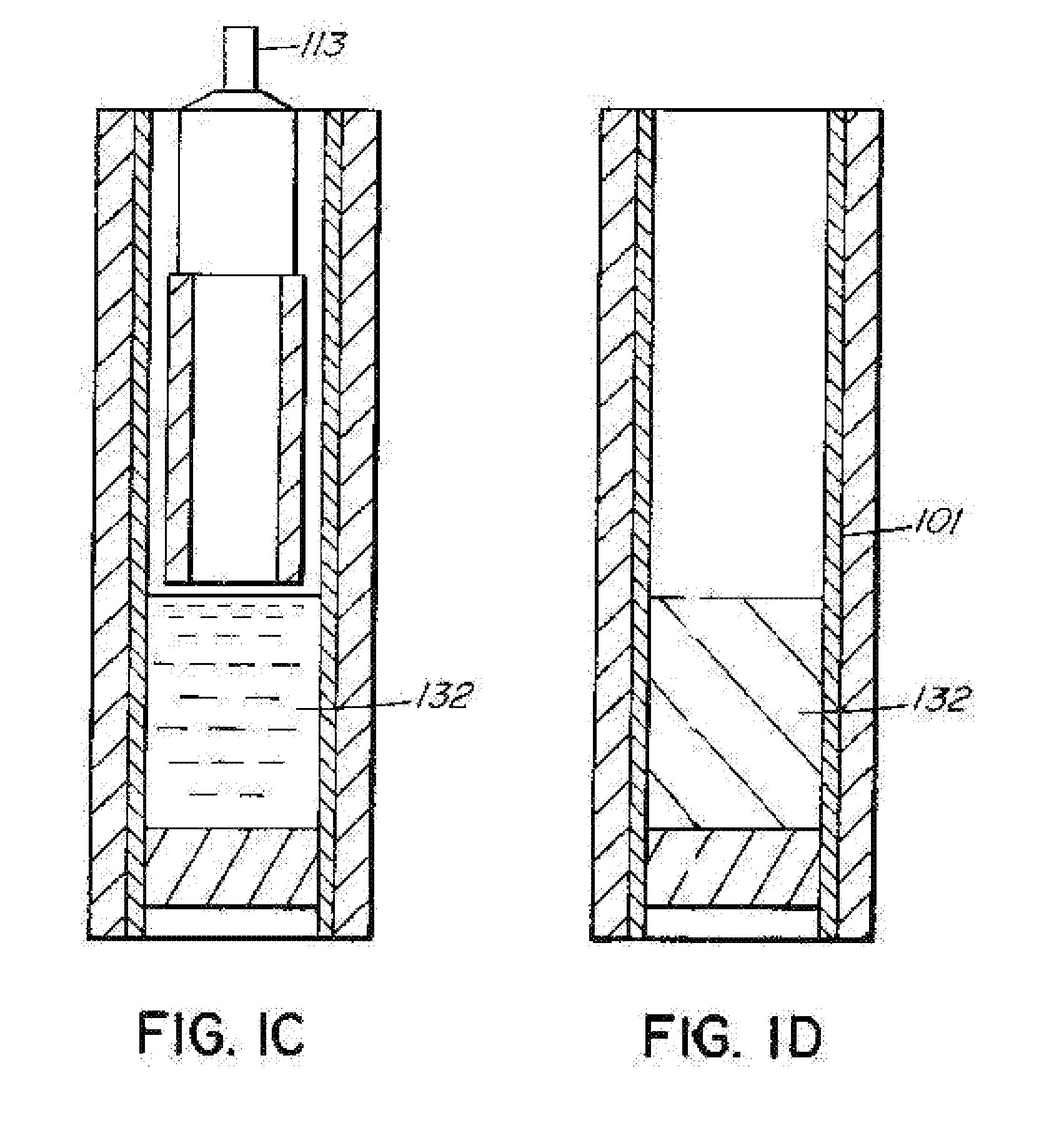

[0016]Referring now to the drawings, an oil or gas well is shown generally in enlarged form at 100 in FIG. 1. It comprises production casing illustrated generally at 101 which is cemented in and surrounded with cement 102. A solid cement plug 103 is illustrated in place at the position of interest within the production casing 101. The setting and formation of the cement plug 103 is well known in the art.

[0017]The components generally used for setting and forming the bismuth-tin alloy plug are best illustrated in FIG. 2. Such components comprise a power control unit 104 located on the surface 114 which also serves as the source of input power, generally 480 volt three-phase alternating current which is subsequently rectified to adjustable voltage DC current for transmission to a heating tool 111. The required power connections 105 are connected to a wireline spool 110 and extend from the spool 110 downhole by way of wireline cables 113 to an attachment 115 of the heating tool 111 whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com