Method for smelting high-nitrogen steel

A smelting method and high-nitrogen steel technology, which is applied in the field of iron and steel smelting, can solve the problems of increased production costs, low nitrogen recovery rate, and zero recovery rate, and achieve the effects of reducing smelting costs, small component fluctuations, and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Smelting of Mn18Cr18N high-nitrogen high-strength steel:

[0030] 1. The chemical composition of 1Mn18Cr18N steel is as follows: (%)

[0031] chemical composition

C

mn

Si

P

S

Cr

N

Al

Required ingredients

≤

0.12

17.50

20.00

≤

0.80

≤

0.050

≤

0.015

17.50

20.00

≥

0.47

≤

0.03

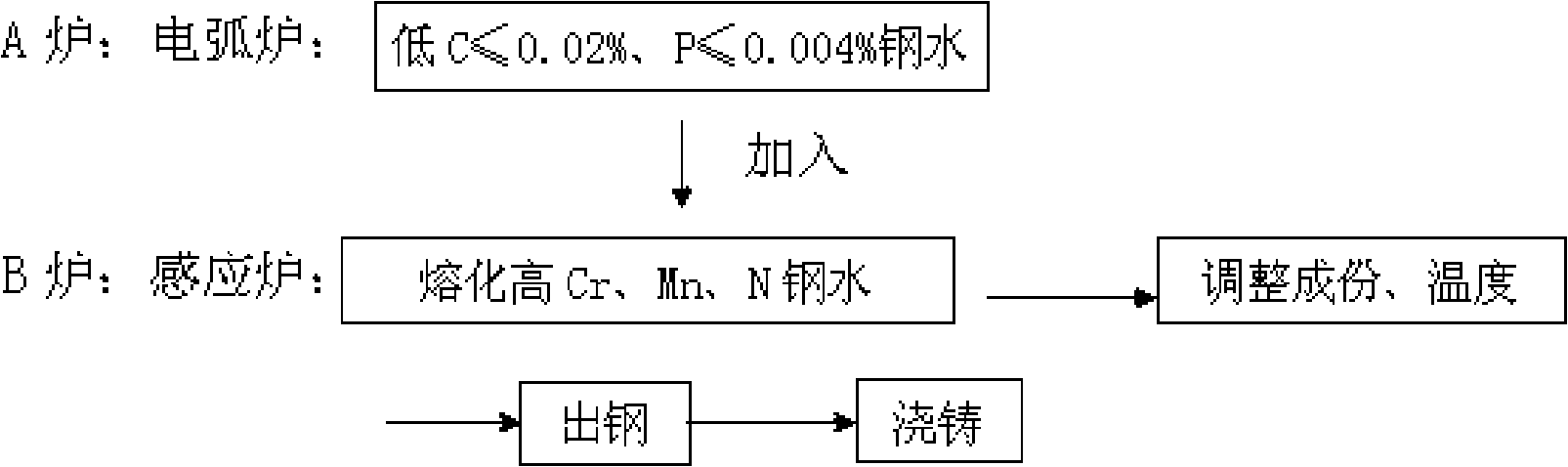

[0032] 2. Process flow

[0033]

[0034] Furnace A: high-quality molten steel with low c and low p content

[0035] Scrap steel + 8 tons of pig iron (electrode blocks can also be used to match carbon), guaranteeing to provide 7 tons of high-quality molten steel for the B-ton furnace. Molten steel C≤0.02%, P≤0.004%; tapping temperature: 1600~1630℃.

[0036] Furnace B: Nitrogen-containing alloy liquid

[0037] Put the metal manganese 3t + ferrochrome nitride 3.70t alloy into the fu...

Embodiment 2

[0039] 1. Smelting of steel FXM-11 for ASTM A965 pressure and high temperature parts austenitic forging body:

[0040] The chemical composition of FXM-11 is as follows: (%)

[0041] chemical composition

C

mn

Si

P

S

Ni

Cr

N

Required ingredients

≤

0.04

8.0

10.0

≤

1.00

≤

0.060

≤

0.030

5.5

7.5

19.0

21.5

0.15

0.40

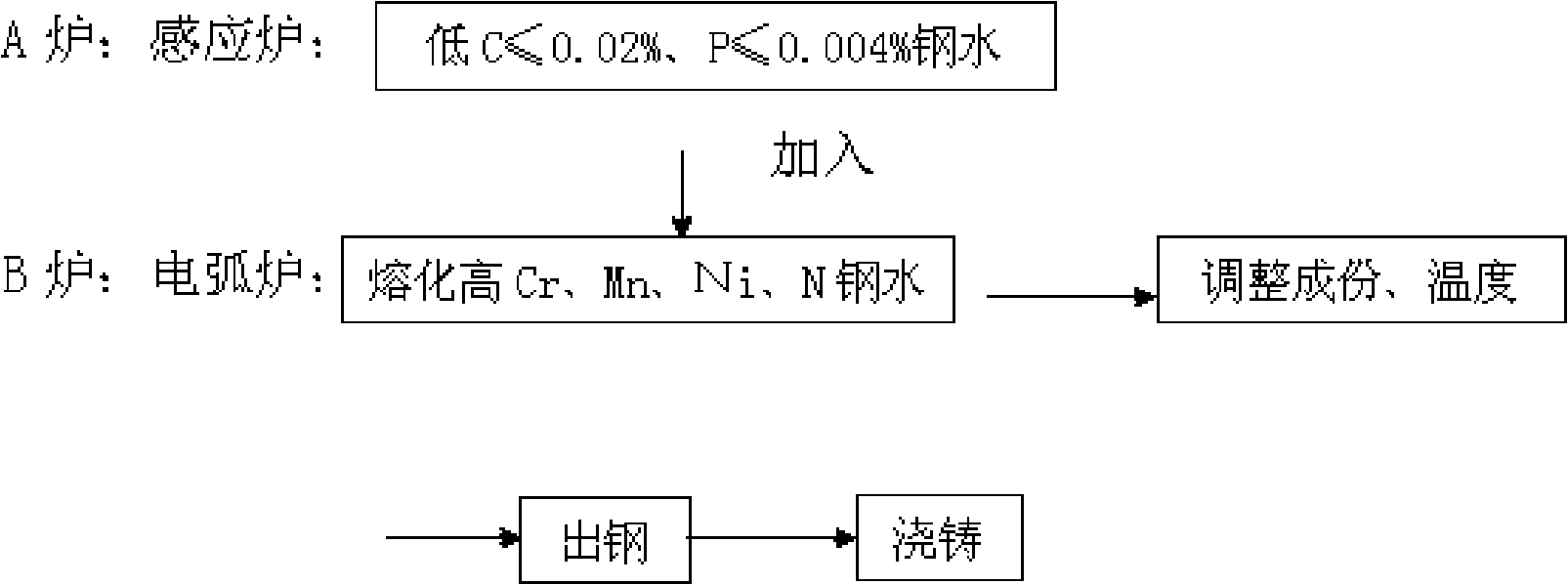

[0042] 2. Process flow

[0043]

[0044] Furnace A: high-quality molten steel with low c and low p content

[0045] Add 2 tons of steel scrap and pig iron to the 1.5-ton furnace (electrode blocks can also be used to mix carbon) to ensure that 2 tons of high-quality molten steel is provided for the 5-ton furnace. Molten steel C≤0.02%, P≤0.004%; tapping temperature: 1630~1660℃.

[0046] Furnace B: Nitrogen-containing alloy liquid

Embodiment 3

[0049]1. The chemical composition of acid-resistant stainless steel 1 Cr18Mn18Ni5Mo3N is as follows: (%)

[0050] chemical composition

C

mn

Si

P

S

Ni

Cr

N

Required ingredients

≤

0.10

8.5

12.0

≤

1.00

≤

0.060

≤

0.030

4.0

6.0

17.0

19.0

0.20

0.30

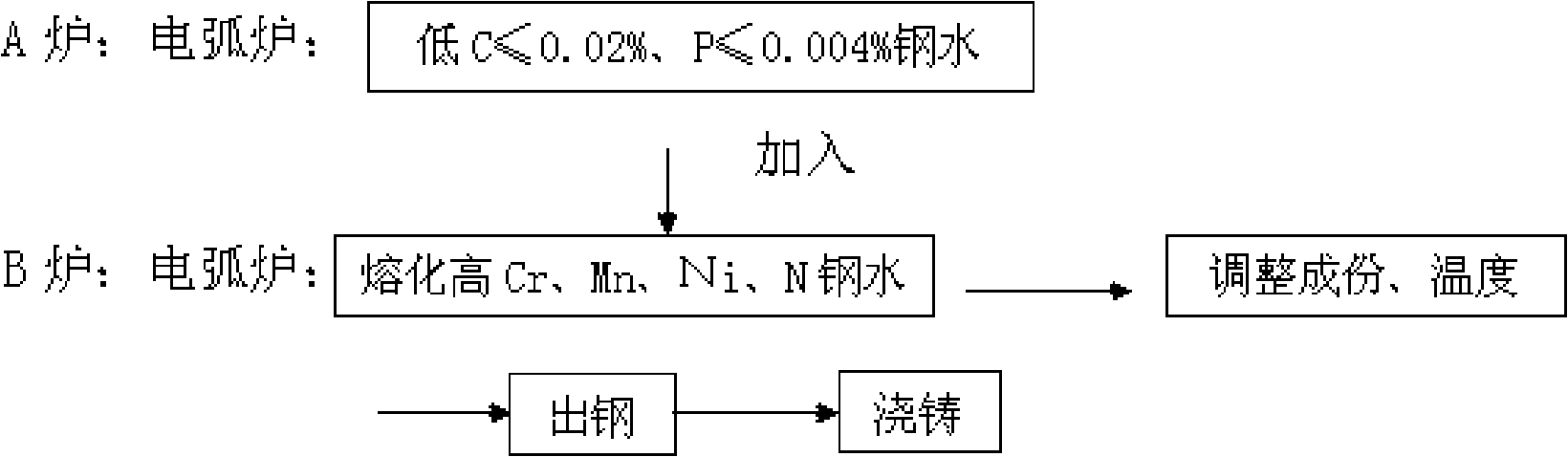

[0051] 2. Process flow

[0052]

[0053] The smelting process of the steel is similar to the first and second embodiments, only the amount of the alloy added is adjusted according to the chemical composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com