Mixing method of high quality low phosphor and sulfur high-alloy steel

A high-alloy steel and high-quality technology, applied in the field of metallurgical industry, can solve the problems of phosphorus, five harmful elements, and trace harmful elements that cannot be controlled

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

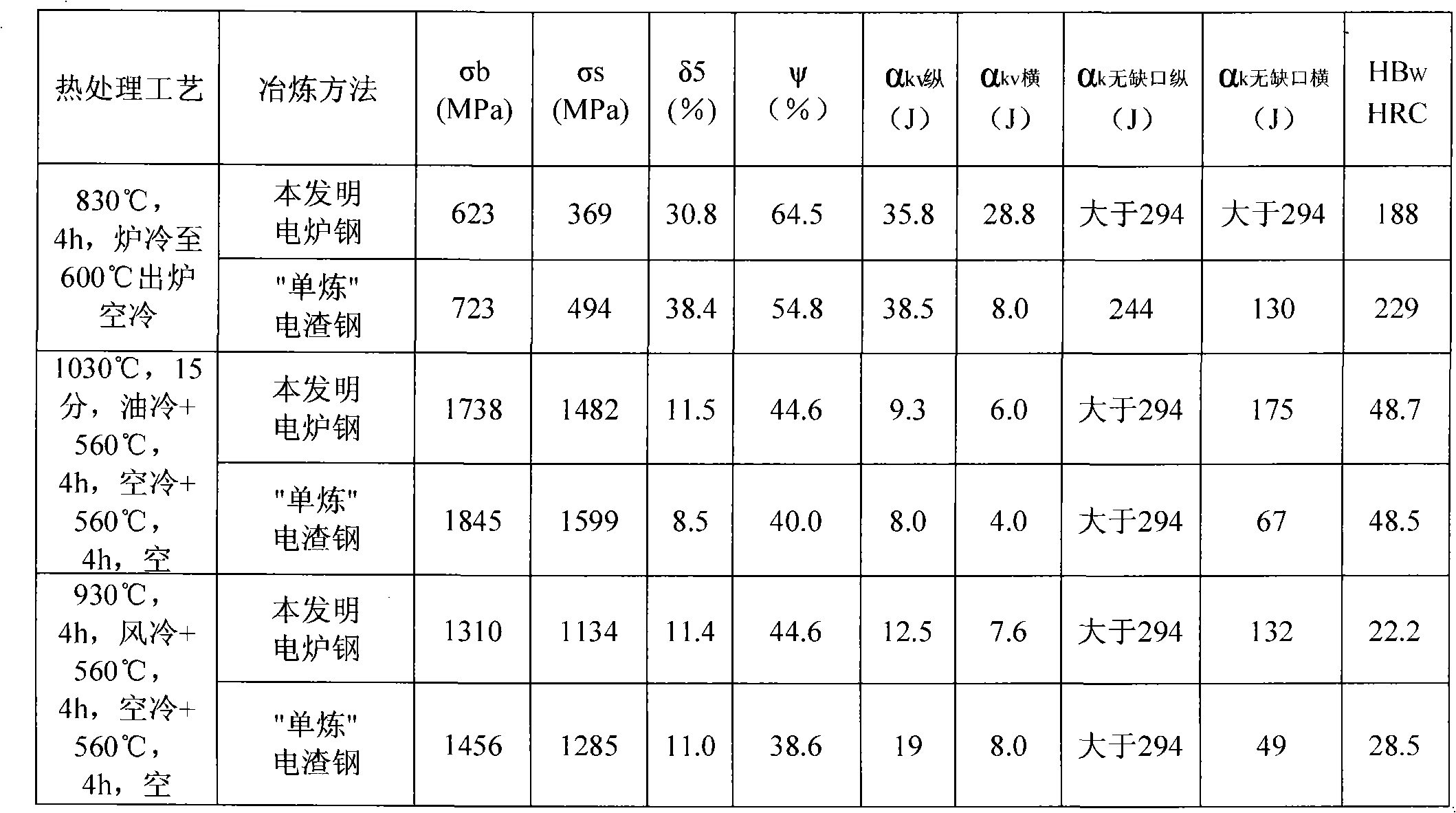

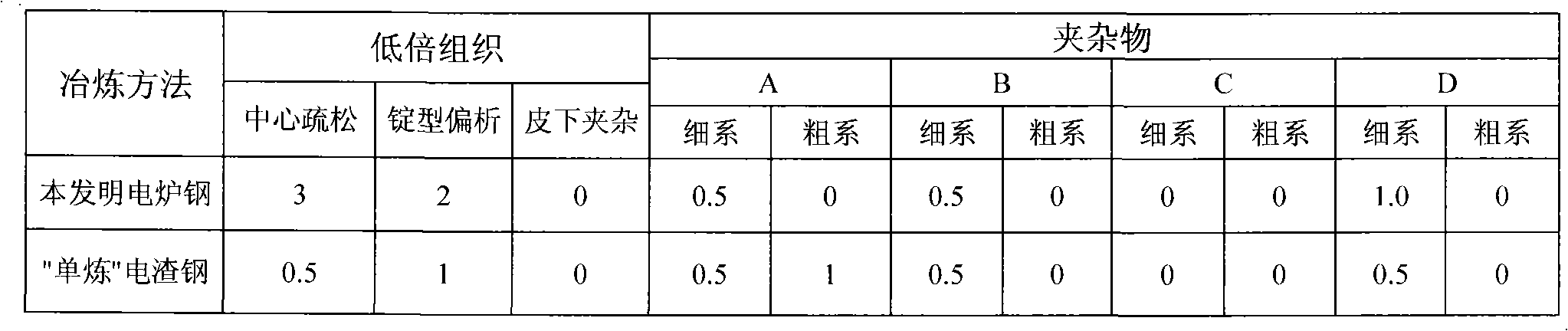

Examples

Embodiment Construction

[0030] Adopt the present invention to produce H13 steel pipe mandrel electroslag steel, its technological operation procedure is as follows:

[0031] One furnace is planned to be smelted, and the technical standard shall be GB1299-2000. Two trays for pouring, one tray for 3t×4 steel ingots. The remaining molten steel is poured into 1.2t electrode rods.

[0032] 1. Chemical Composition (%)

[0033] The user's requirements for the basic composition of the finished product (%):

[0034] grade

C

mn

Si

P+S

S

Cr

Mo

V

4Cr5MoSiV1

(electroslag)

0.30

0.39

≤

0.60

0.70

1.20

≤

0.020

≤

0.008

4.50

5.50

1.00

1.50

0.78

1.20

GB1299-2000

0.32

0.45

0.20

0.50

0.80

1.20

P≤

0.030

≤

0.030

4.75

5.50

1.10

1.75

0.80

1.20

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com