Additive manufacturing method for electric arc filler wire and device

An additive manufacturing and wire filling technology, applied in the field of additive manufacturing, can solve the problems of substandard quality of parts and easy generation of a large number of pores, and achieve the effects of improving the structure and properties, removing pore defects, and refining grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing.

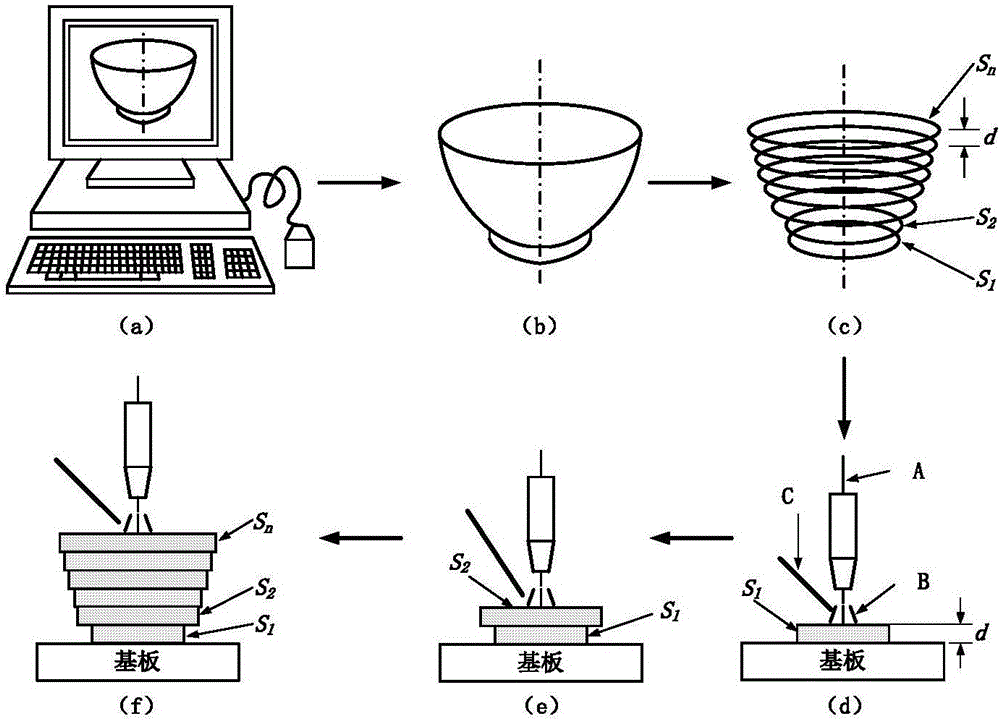

[0035] Please refer to figure 1 , figure 1 For the working principle figure of the additive manufacturing method provided by the present invention, at first, utilize drawing software (such as three-dimensional CAD software) to draw the three-dimensional model (such as three-dimensional CAD software) of required component on computer figure 1 shown in (a)), and the model built by the slicing software (ie figure 1 (as shown in (b)) in the layer slice processing, to obtain the two-dimensional profile of each layer section (as shown in (c)); secondly, after processing the slice data of these two-dimensional profiles, use programming technology to generate The trajectory code of the welding torch; finally, the method of arc-filling additive manufacturing is adopted, as shown in (d), A is the tungsten electrode, which is set on the welding torch, C is the welding wire, and B is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com