Cold ring rolling forming method for double-flute section ring

A technology of cold rolling and double grooves for rings, which is applied in metal processing equipment, metal rolling, manufacturing tools, etc., to reduce production costs, reduce consumption of raw materials and processing hours, and improve streamline distribution and organizational performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

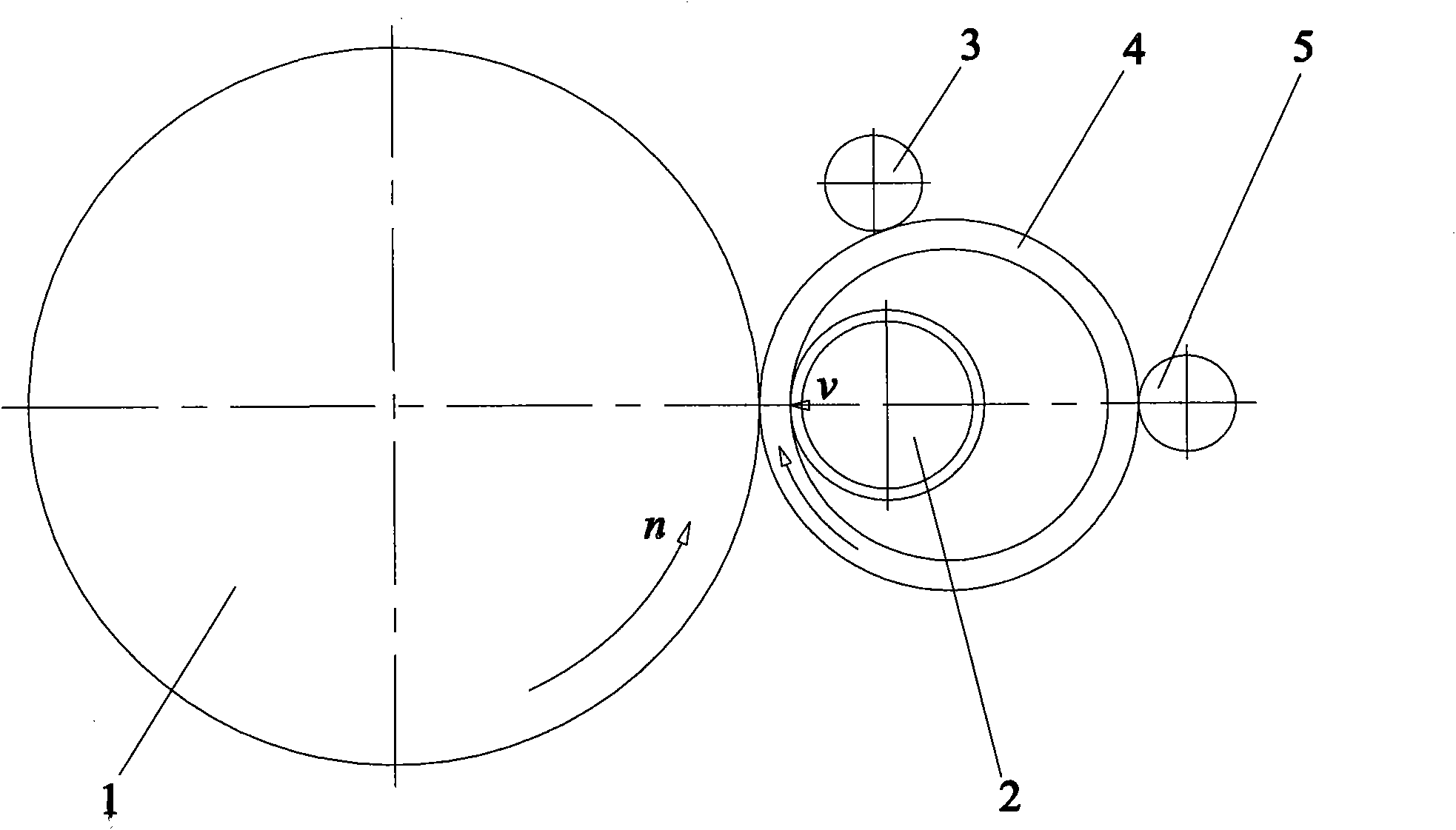

[0059] The cold rolling and expanding forming method of the double-groove cross-section ring is realized according to the following steps:

[0060] 1) Billet making: evenly heat the bar section from room temperature to the forging temperature of high plasticity and low resistance, and then upsetting, punching, punching and skinning the hot section to make a ring blank for rolling.

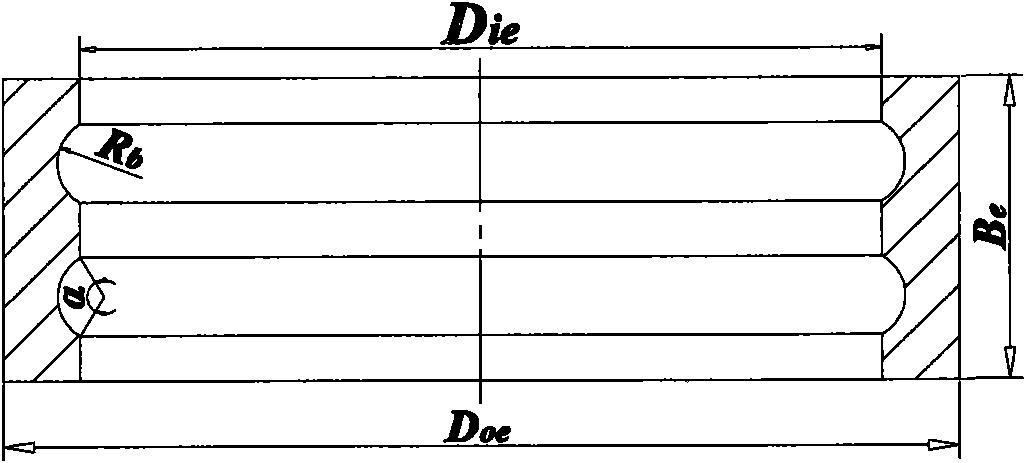

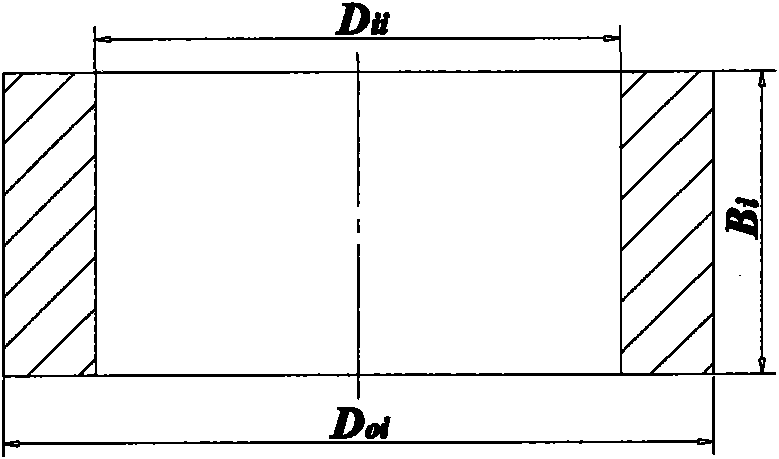

[0061] Such as figure 1 As shown, the outer diameter of the GCr15 steel double-groove section ring that requires rolling and expanding oe 62mm, inner diameter D ie is 52.5mm, the central angle α of the double-groove cross-section ring groove is 91°, and the double-groove cross-section ring groove arc radius R b 4.64mm, double groove section ring width B e 20mm. According to the design method of the ring blank, the rolling and expanding ratio is taken as 1.36, and the outer diameter of the ring blank for rolling and expanding is designed D oi is 45.64mm, the inner diameter of the ring blank D ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| velocity | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com