Additive manufacturing method and device for large metal part

A technology for additive manufacturing and metal parts, which is applied in the field of additive manufacturing methods and devices for large metal parts, can solve the problems of inability to manufacture complex metal components, difficulty in controlling metallurgical defects, and high tonnage requirements of forging presses, and achieves reduction of residual stress. and deformation and cracking tendency, excellent mechanical properties, the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The production of super-large 304 stainless steel tubular parts, the outer diameter of the part is 1500mm, the inner diameter is 1200mm, and the length is 3000mm. The specific steps are as follows:

[0058] (1) Obtain the 3D CAD model of the part, slice the model, and then extract the data of the inner and outer contours of each layer, and generate the deposition path accordingly;

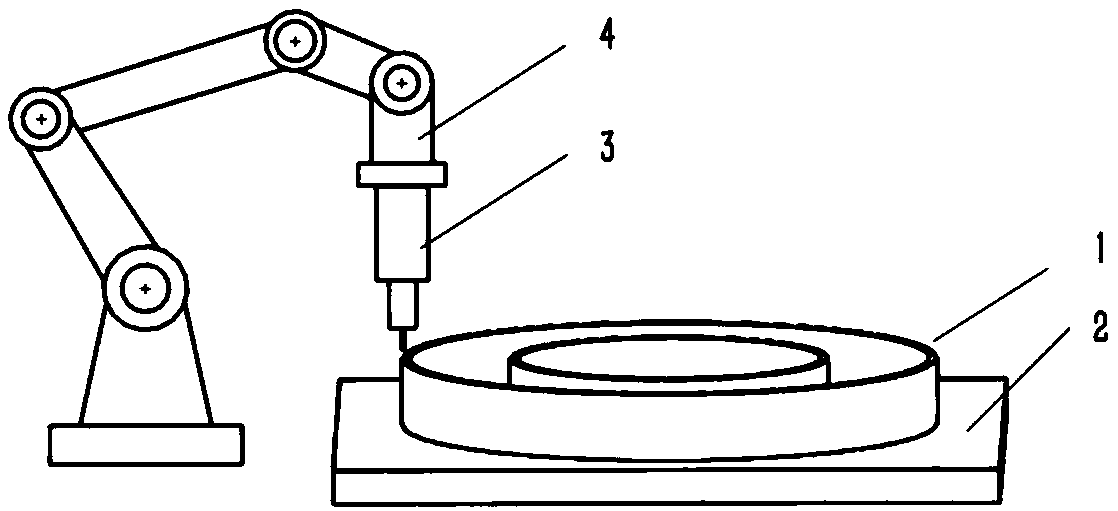

[0059] (2) Using arc additive manufacturing technology, several layers are deposited on the substrate according to the generated deposition path to form a metal cavity with a wall thickness of 10mm and a height of 50mm. The welding wire used in arc additive manufacturing is 304 stainless steel with a diameter of 1.2mm Welding wire, the welding current is 200A, the voltage is 20V, and the welding speed is 4.5mm / s;

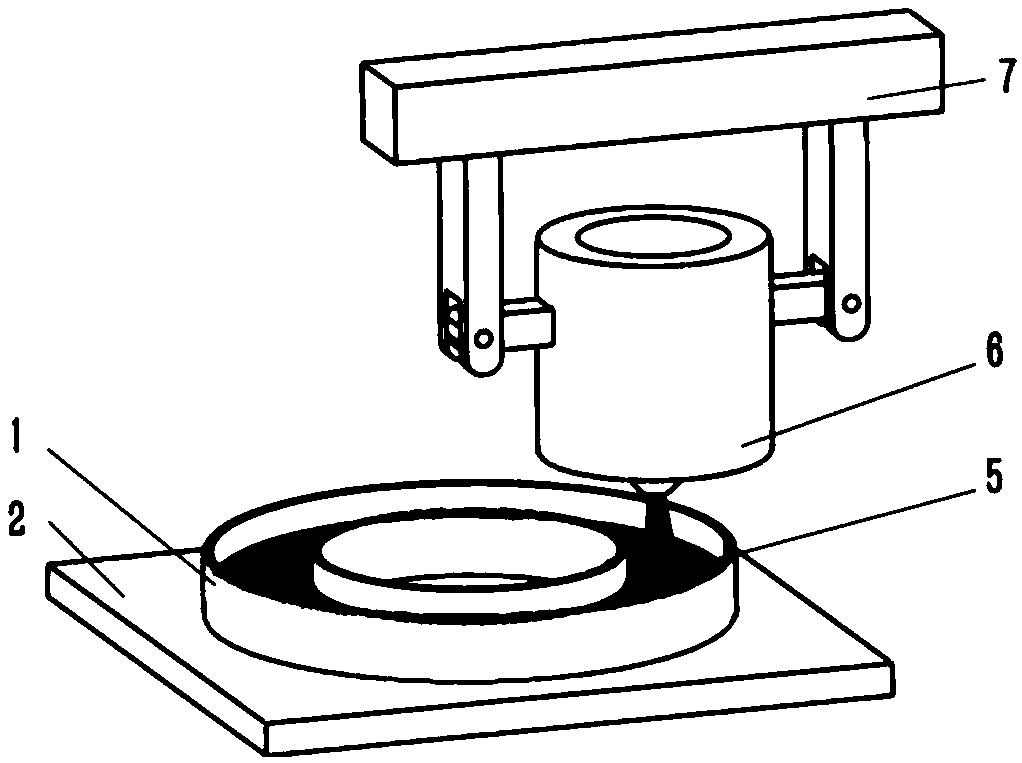

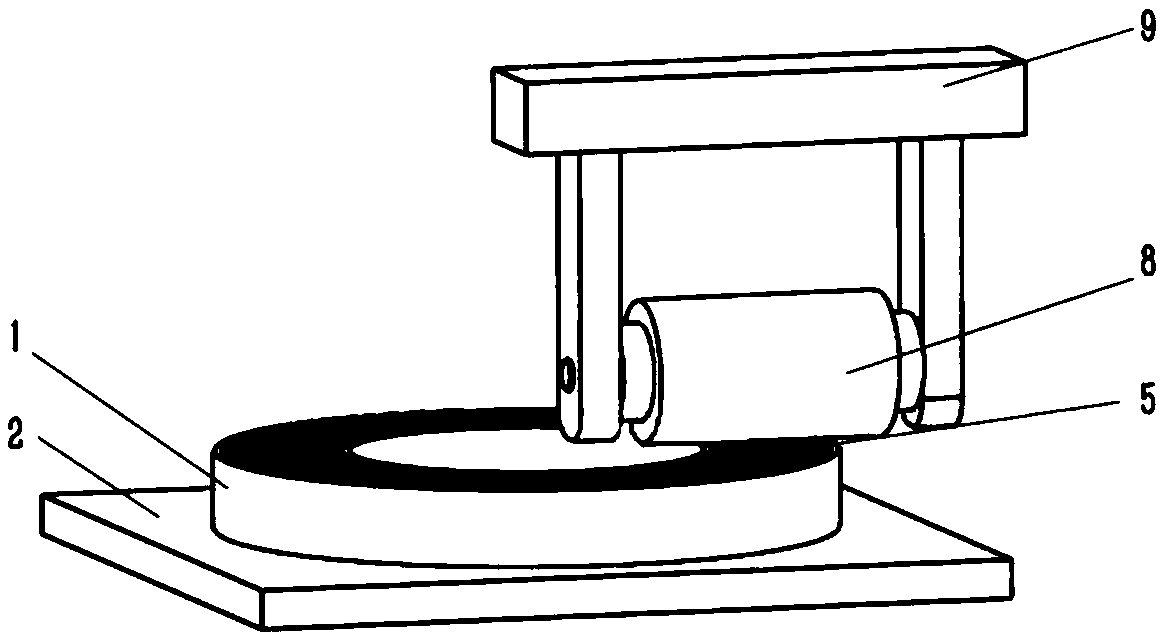

[0060] (3) The casting movement mechanism moves the casting equipment to the top of the metal cavity, injects the smelted 304 stainless steel into the metal cavity until it fills ...

Embodiment 2

[0064] The production of super-large tubular parts, the outer diameter of the part is 1500mm, the inner diameter is 1200mm, and the length is 3000mm. The surface layer of the part is 304 stainless steel, and the core is Q235. The specific steps are as follows:

[0065] (1) Obtain the 3D CAD data model of the part, slice the model, then extract the data of the inner and outer contours of each layer, and generate the deposition path;

[0066] (2) Using arc additive manufacturing technology, several layers are deposited on the substrate according to the generated deposition path to form a metal cavity with a wall thickness of 5 mm and a height of 10 mm. The arc additive manufacturing uses 304 stainless steel welding wire with a diameter of 1.2 mm. The current is 200A, the voltage is 20V, and the welding speed is 4.5mm / s;

[0067] (3) The casting movement mechanism moves the casting equipment to the top of the metal cavity, injects the smelted Q235 molten steel into the metal cavi...

Embodiment 3

[0071] Such as Figure 6 As shown, the production of large spherical parts, the outer diameter of the part is 1400mm, the inner diameter is 1000mm, and the material of the part is 316 stainless steel. The specific steps are as follows:

[0072] (1) Obtain the 3D CAD data model of the part, slice the model, then extract the data of the inner and outer contours of each layer, and generate the deposition path;

[0073](2) Using arc additive manufacturing technology, several layers are deposited on the substrate according to the generated deposition path to form a metal cavity with a wall thickness of 20 mm and a height of 70 mm. The welding wire used in arc additive manufacturing is 316 stainless steel with a diameter of 1.2 mm Welding wire, the welding current is 185A, the voltage is 20V, and the welding speed is 5.4mm / s;

[0074] (3) The casting movement mechanism moves the casting equipment to the top of the metal cavity, injects the smelted 316 stainless steel liquid into th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com