Al-Mg-Si system aluminum alloy extrusion profile and production process thereof

A technology of extrusion profile and production process, which is applied in the field of Al-Mg-Si aluminum alloy extrusion profile and its production process, which can solve problems such as cracks, component failure, and unqualified bending performance, so as to improve the yield of products , Improve tissue performance, excellent bending performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

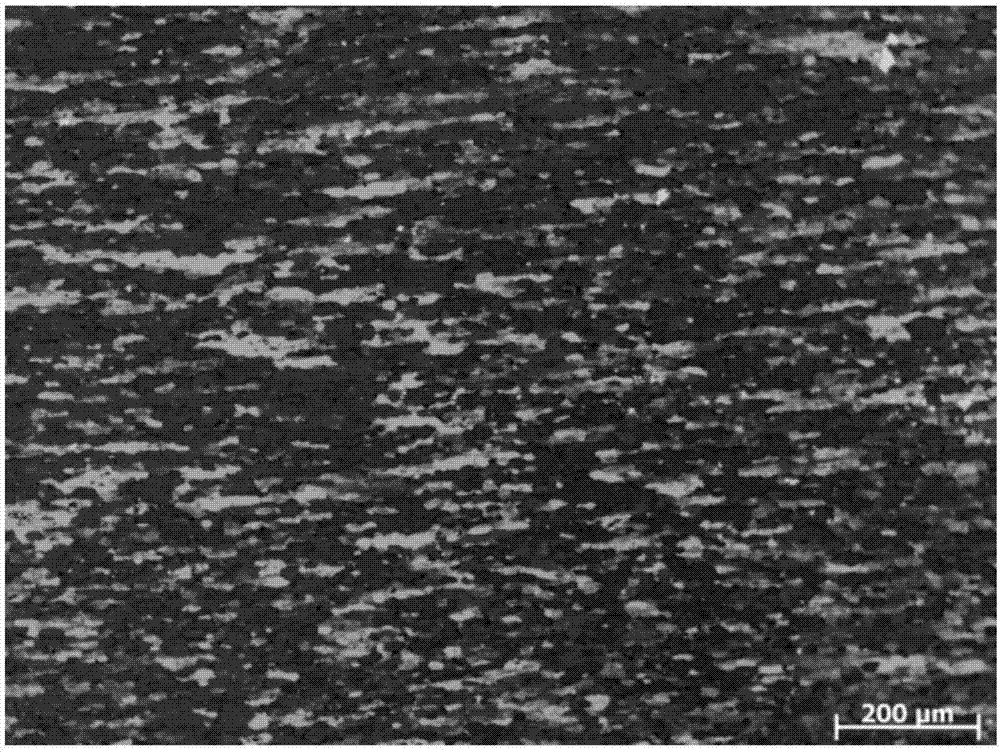

[0046] Embodiment 1 provides a kind of Al-Mg-Si series aluminum alloy extruded profile, and it adopts following production process to make:

[0047] Raw materials are configured according to the composition of alloy elements: Si: 0.65%, Fe: 0.2%, Mg: 0.45%, Cu: 0.15%, Mn: 0.25%, Cr: 0.15%, Ti: 0.07%, Zn: 0.1%, and the balance Consists of Al and unavoidable impurities.

[0048] The above-mentioned raw materials are subjected to homogenization treatment, specifically, the temperature is raised to 530° C. at a heating rate of 30° C. / h, and the temperature is maintained for 12 hours to obtain a casting billet.

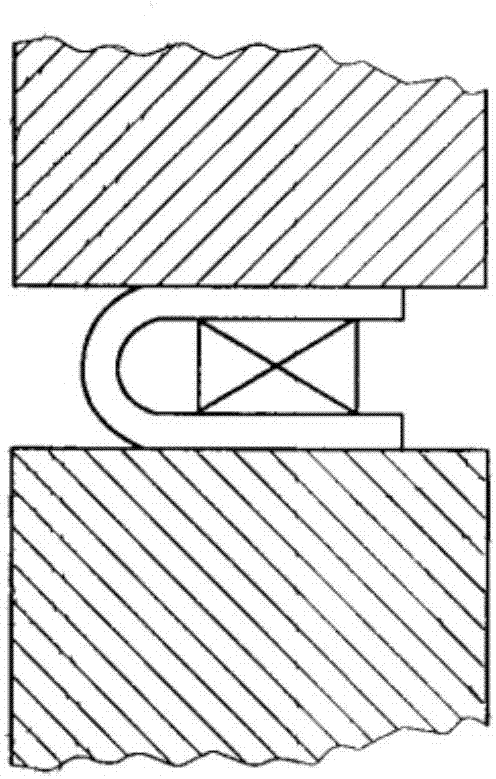

[0049] The casting billet is hot-extruded, specifically, the casting billet is heated to 500°C, the temperature gradient of the casting billet is 10°C, and the casting billet is extruded, the temperature of the extrusion cylinder is 460°C, and the temperature of the extrusion mold is 490°C , the outlet temperature of the hot extrusion is 510°C, the extrusion speed is 1.5m...

Embodiment 2

[0053] Embodiment 2 provides an Al-Mg-Si series aluminum alloy extruded profile, which is obtained by the following production process:

[0054] Raw materials are configured according to the composition of alloy elements: Si: 0.75%, Fe: 0.25%, Mg: 0.55%, Cu: 0.2%, Mn: 0.35%, Cr: 0.2%, Ti: 0.07%, Zn: 0.1%, and the balance Consists of Al and unavoidable impurities.

[0055] The above-mentioned raw materials are subjected to homogenization treatment, specifically, the temperature is raised to 530° C. at a heating rate of 30° C. / h, and the temperature is maintained for 12 hours to obtain a casting billet.

[0056] The casting billet is hot-extruded, specifically, the casting billet is heated to 500°C, the temperature gradient of the casting billet is 10°C, and the casting billet is extruded, the temperature of the extrusion cylinder is 460°C, and the temperature of the extrusion mold is 480°C , the exit temperature of the hot extrusion is 515°C, the extrusion speed is 1.8mm / s, an...

Embodiment 3

[0059] Embodiment 3 provides an Al-Mg-Si series aluminum alloy extruded profile, which is obtained by the following production process:

[0060] Raw materials are configured according to the composition of alloy elements: Si: 0.85%, Fe: 0.3%, Mg: 0.65%, Cu: 0.25%, Mn: 0.45%, Cr: 0.25%, Ti: 0.05%, Zn: 0.1%, and the balance Consists of Al and unavoidable impurities.

[0061] The above-mentioned raw materials are subjected to homogenization treatment, specifically, the temperature is raised to 530° C. at a heating rate of 30° C. / h, and the temperature is maintained for 12 hours to obtain a casting billet.

[0062] The casting billet is hot-extruded, specifically, the casting billet is heated to 480°C, the temperature gradient of the casting billet is 10°C, and the casting billet is extruded, the temperature of the extrusion cylinder is 460°C, and the temperature of the extrusion mold is 500°C , the outlet temperature of hot extrusion is 510°C, the extrusion speed is 2mm / s, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com