Excel-based product process planning method

An excel and process technology, applied in the field of product process preparation based on excel, can solve problems such as error-prone, labor-intensive, and omission of revisions, and achieve the effect of ensuring consistency, high work efficiency, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

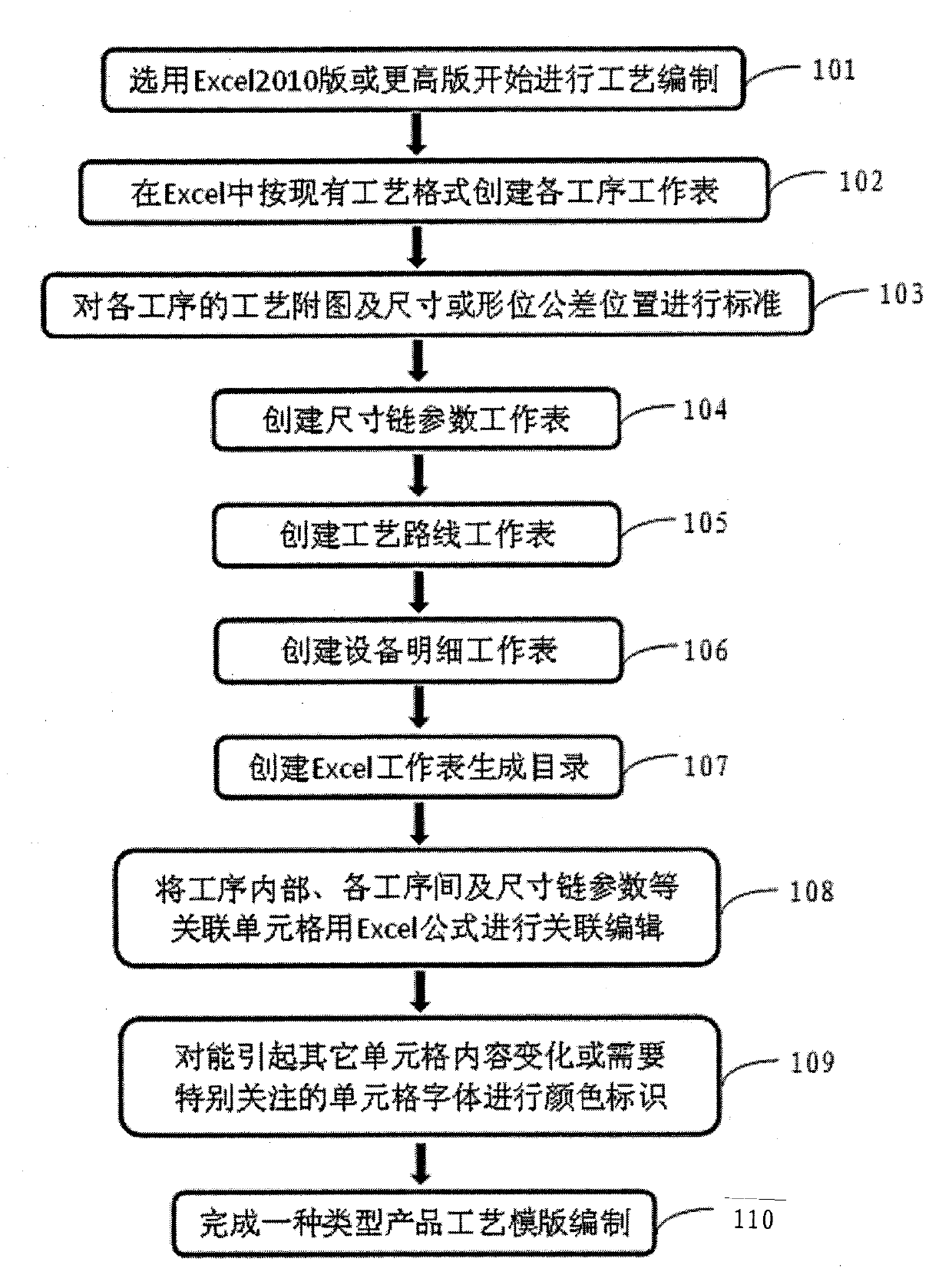

Method used

Image

Examples

Embodiment Construction

[0045] In this embodiment, the processing technology of the engine intake valve is taken as an example, and the processing technology of the engine intake valve is compiled by using the product process preparation method of excel.

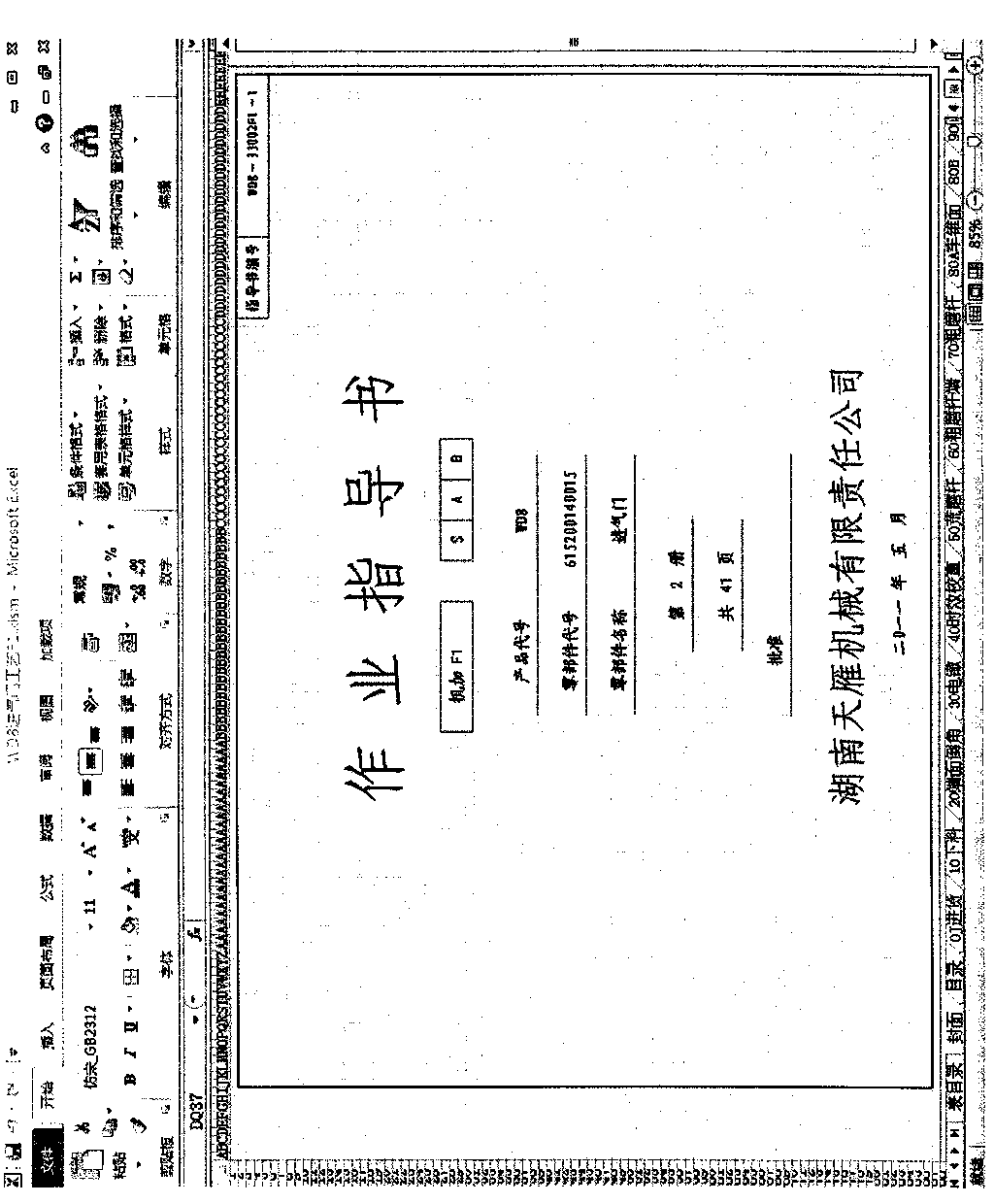

[0046] attached figure 2 It is a schematic diagram of the intake valve work instruction (hereinafter referred to as the intake valve process), with figure 2 Shown in is the cover of the intake valve operation instruction booklet, with figure 2 The content marked in blue in the middle indicates that the change of the content will cause the change of other content or the content needs to be changed when the process is compiled.

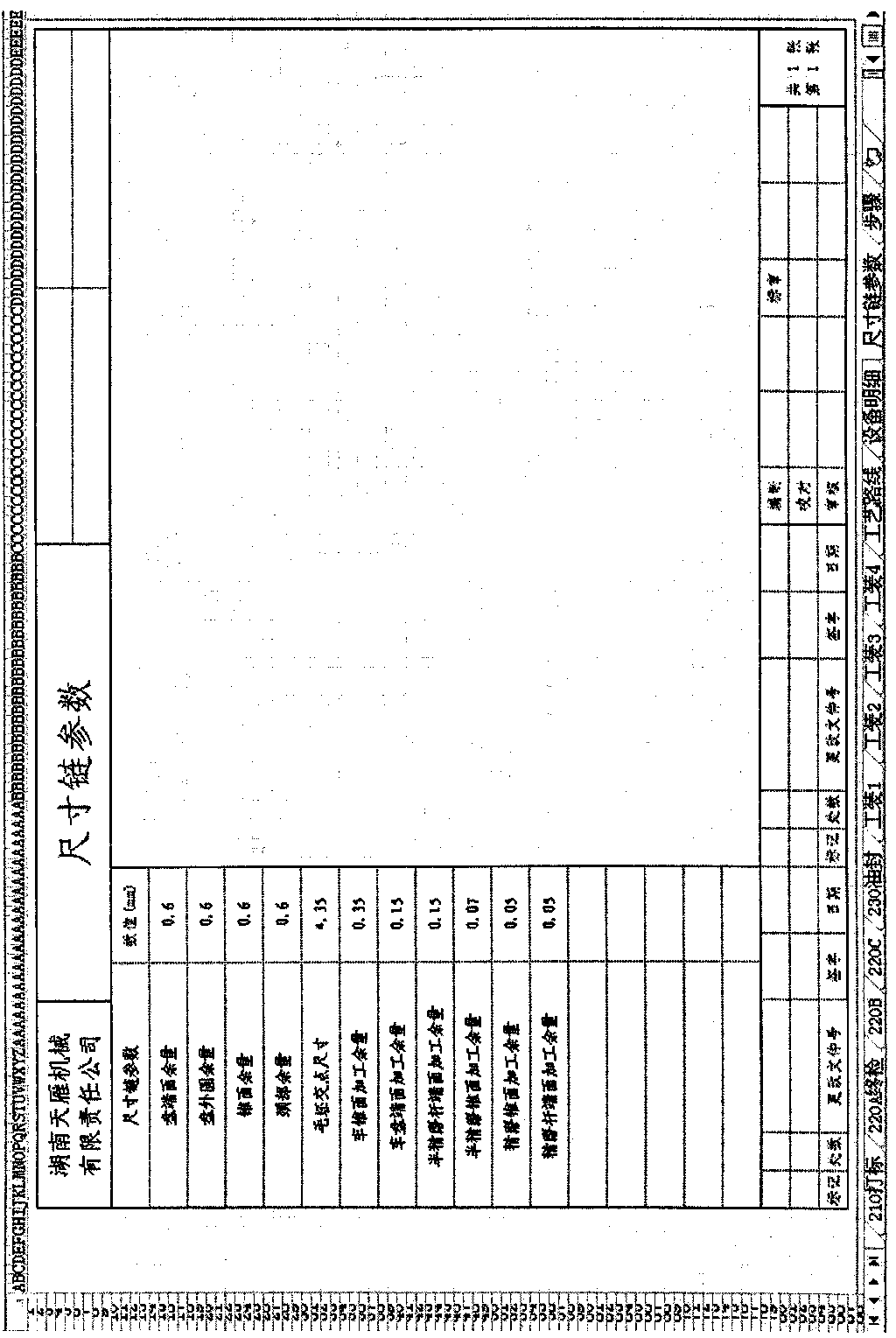

[0047] attached image 3 Create a directory for the worksheet of the intake valve process, the implementation method is as follows: first create a blank worksheet of "Table Directory", select cell B1, click "Define Name" in "Formula", and in the pop-up "New Name" "Input the name List, enter =INDEX(GET.WORKBOOK(1), $A1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com