Double-end-face over-locating fixture

A technology of over-positioning and double-end faces, which is applied in the direction of expanding the mandrel, etc., can solve the problems of unstable process dimensions, etc., and achieve the effect of small elastic deformation recovery, control of plastic deformation, and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing the present invention is described in further detail:

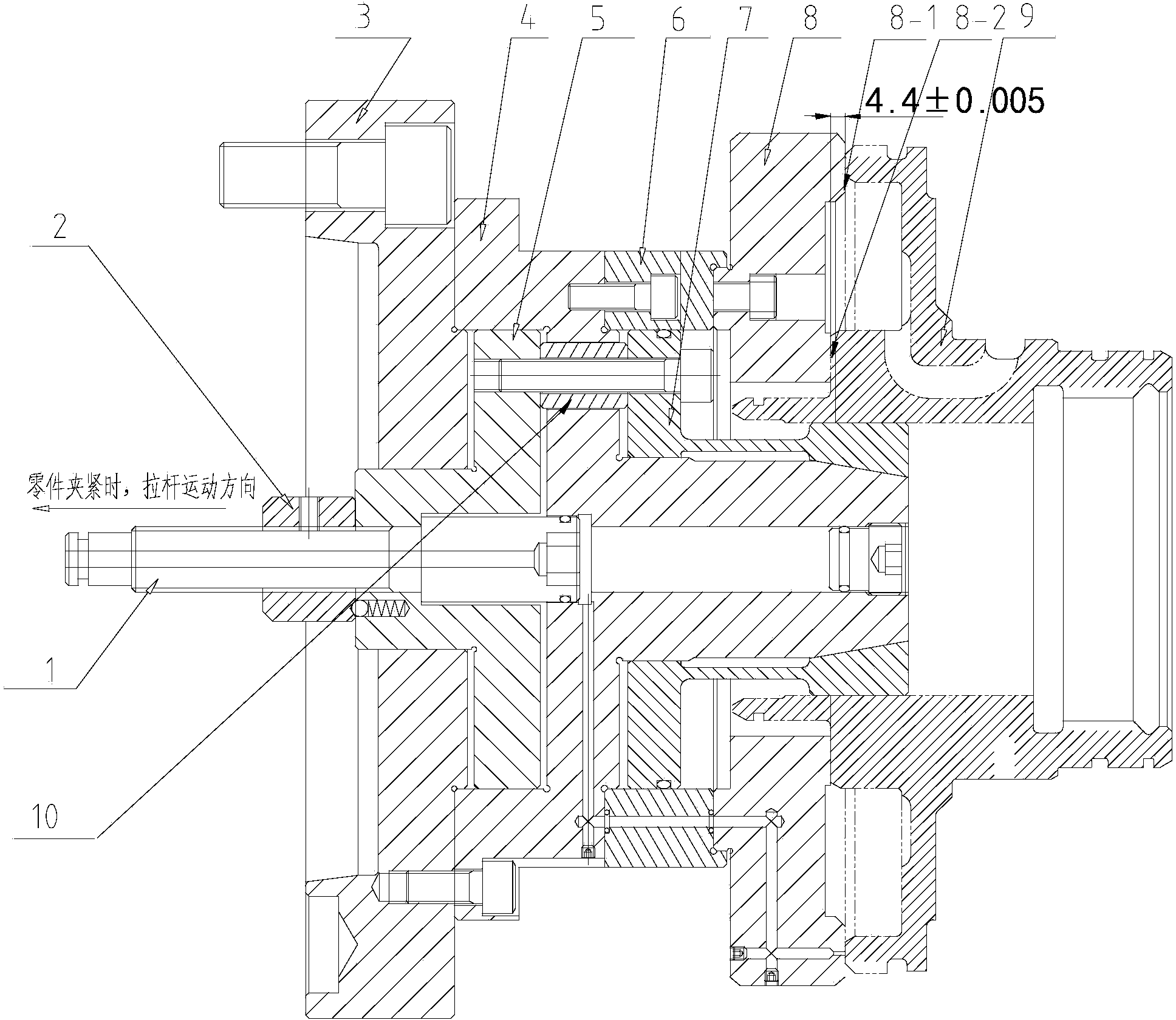

[0016] Such as figure 1 As shown, its main structure consists of the following components:

[0017] Pull rod: connected to the hydraulic cylinder to transmit the pulling force;

[0018] Connecting plate: Cooperate with the tie rod to transmit the pulling force of the tie rod, and at the same time ensure the centering installation of the mandrel;

[0019] Mandrel: It is fixedly connected with the machine table, and the end face is connected with a support plate, which can adjust the axial positioning;

[0020] Support plate: The end surface is connected with a positioning pad, and its inner hole cooperates with the expansion sleeve to ensure the centering movement of the expansion sleeve along the axial direction;

[0021] Over positioning pad: The over positioning pad is connected to the connection plate, and the axial position can be adjusted according to the thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com