Solid electrolytic capacitor and its manufacturing method

A manufacturing method and solid electrolyte technology, applied in solid electrolytic capacitors, electrolytic capacitors, capacitors, etc., can solve the problems of incorrect anode lead frame position accuracy, deterioration of connection strength, poor tightness, etc., to achieve easy operation and improve ESP characteristics , the effect of improving welding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be described below.

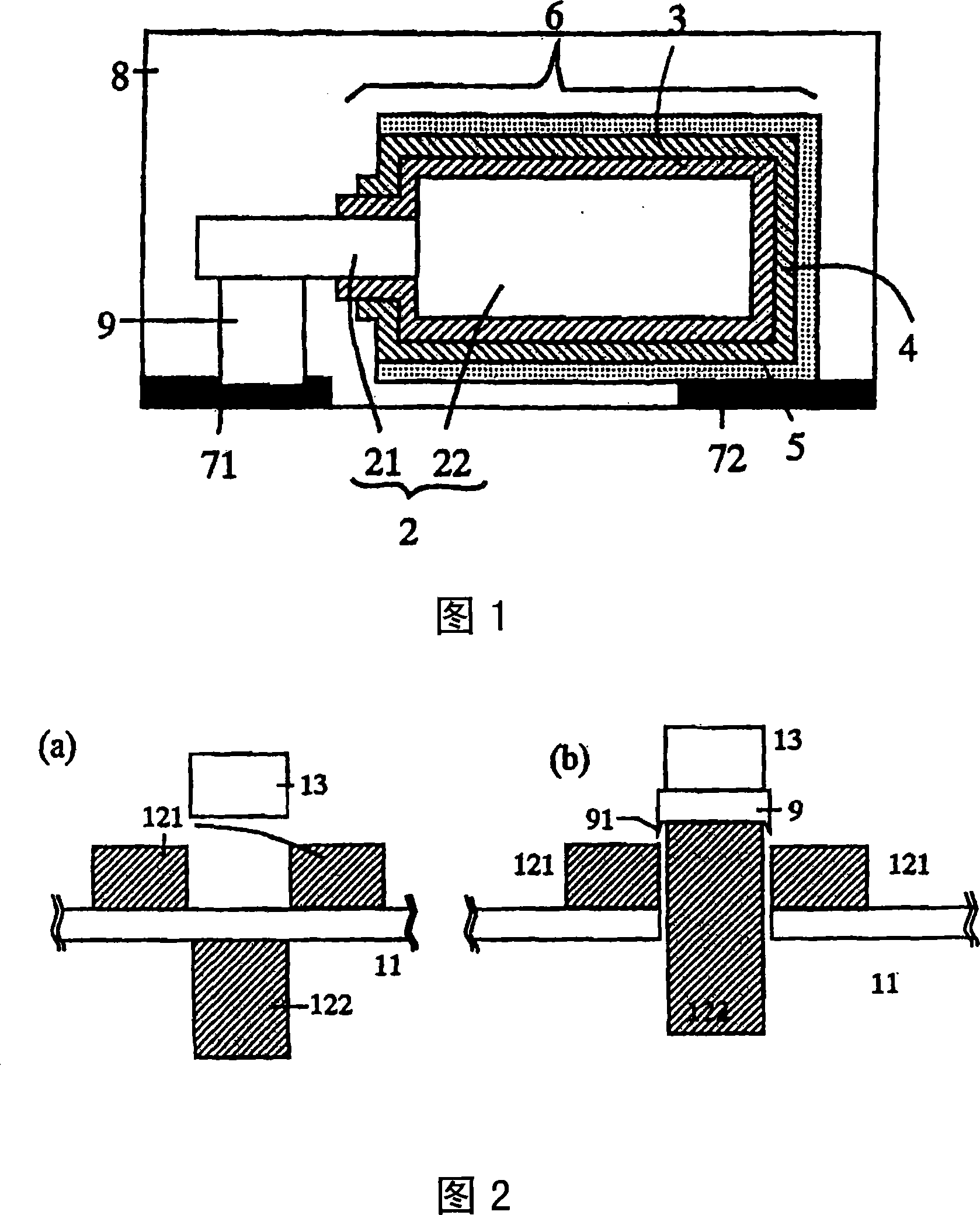

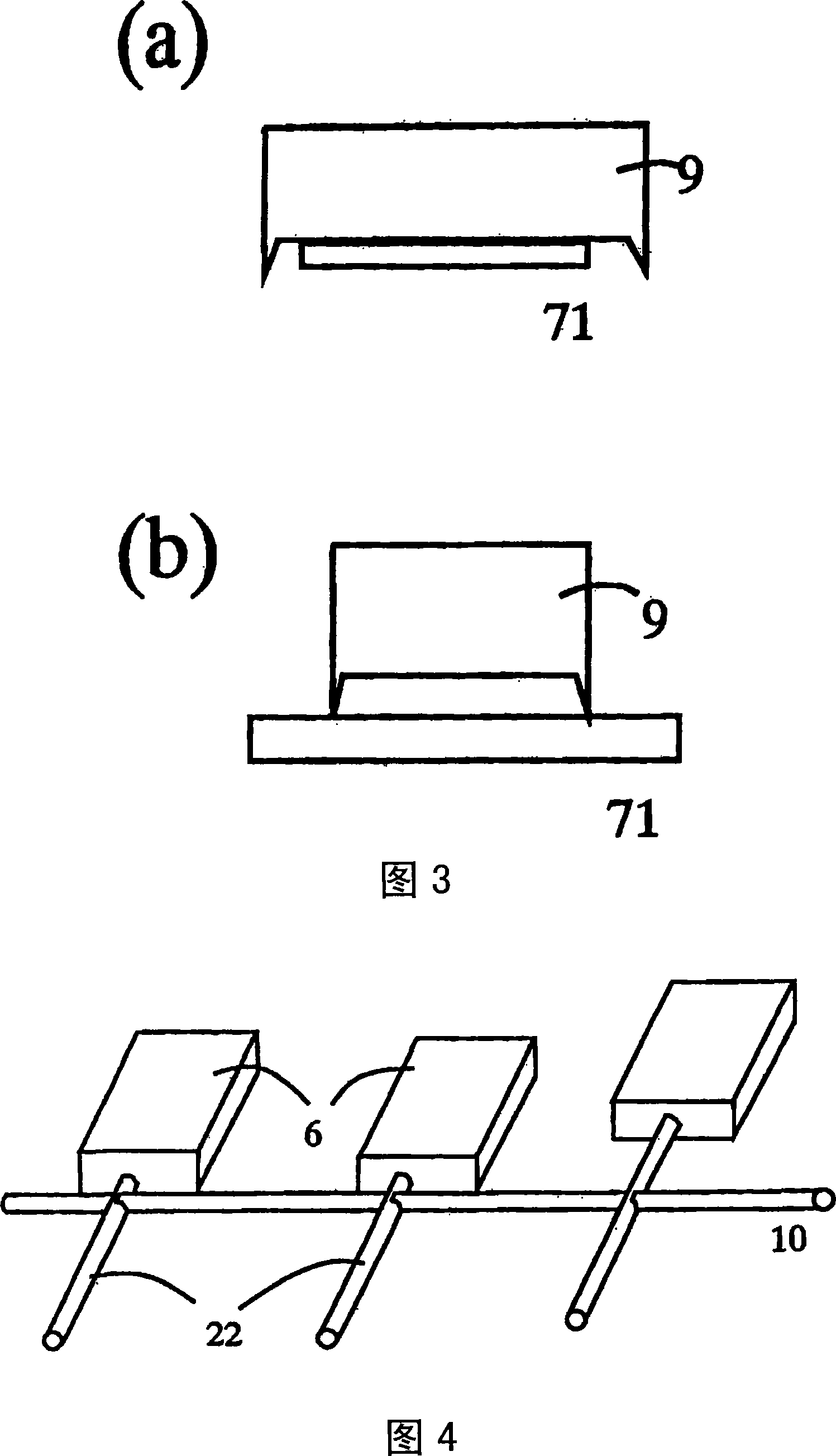

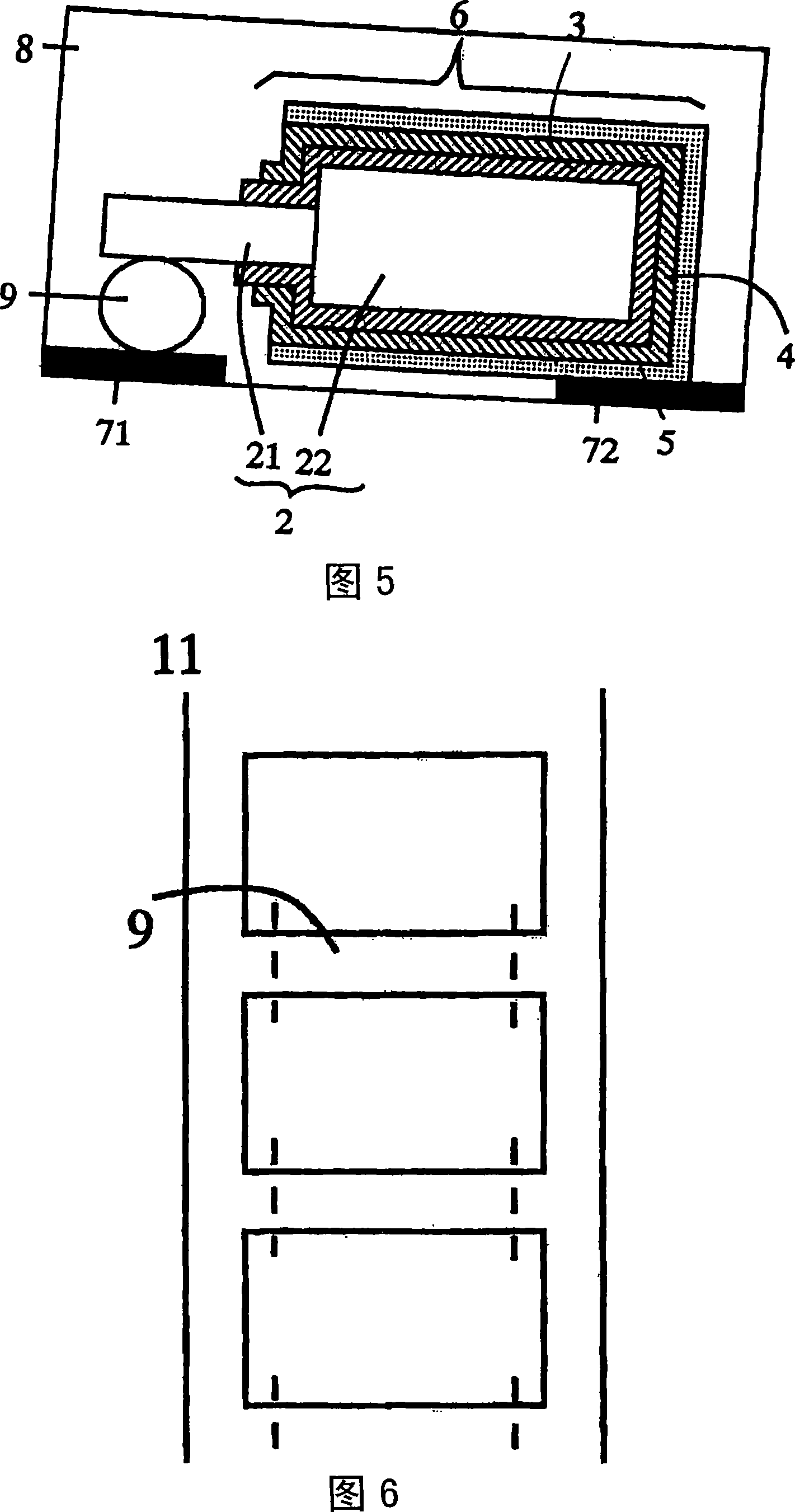

[0027] FIG. 1 is a cross-sectional view of a solid electrolytic capacitor according to an embodiment of the present invention. The solid electrolytic capacitor comprises a capacitor element (6) and a pillow (9) provided between the capacitor element (6) and the anode lead frame (71), and the anode lead frame (71) and the cathode lead frame (72) The lower part of the body is covered with exterior resin (8) in a state where it is exposed.

[0028] The above-mentioned capacitor element (6), as its manufacturing process, is formed by sequentially forming a dielectric oxide film (3) and a cathode composed of a solid electrolyte on the outer peripheral surface of the sintered body (22) made of a valve action metal from which the anode lead (21) is drawn out. layer (4), silver paste (paste) or carbon cathode lead-out layer (5).

[0029] Here, the so-called valve action metal refers to a metal that forms an extre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com