Angle positioning clamp capable of being adjusted by 360 degrees

An angle positioning and angle adjustment technology, applied in positioning devices, clamping, manufacturing tools, etc., can solve the problems of unsuitable for mass production, unfavorable for mass production, expensive machine tools, etc., and achieve simple and reliable clamping and wide application range Wide, simple and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

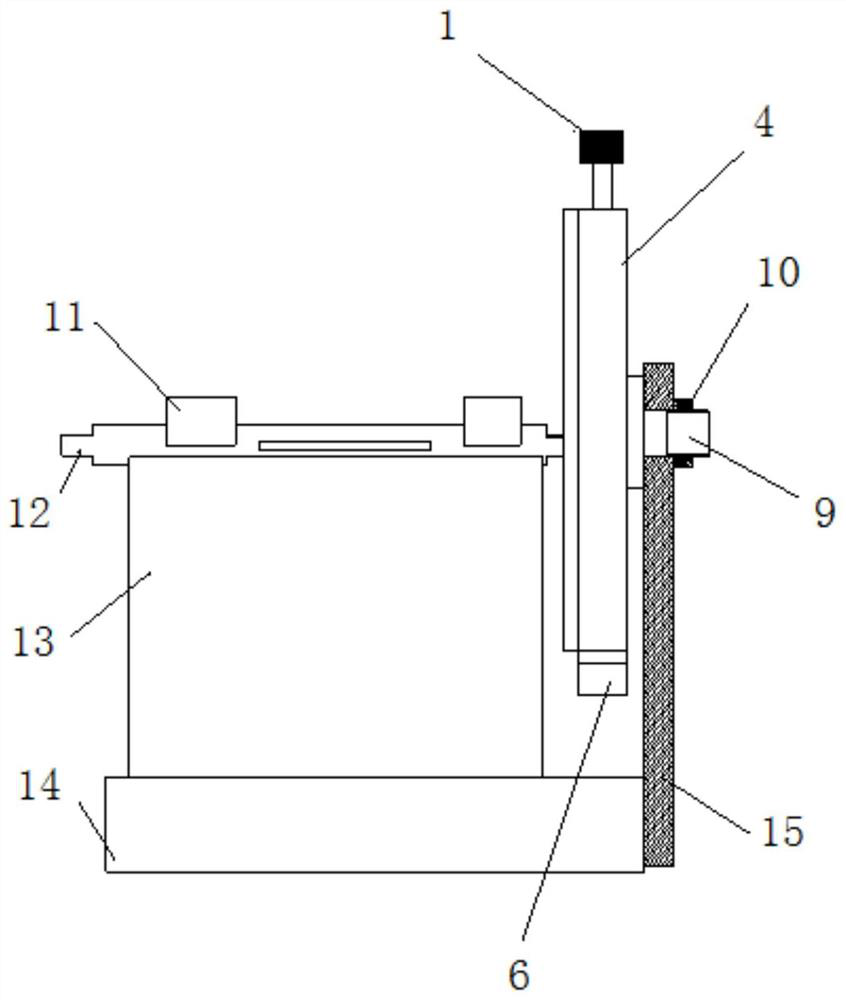

[0039] In order to realize the rapid positioning and clamping of shaft parts with included angles on the circumference, etc., this embodiment provides an angle positioning fixture that can be adjusted 360 degrees. For its structure, see figure 1 As shown, it includes a base 14 on the working table of the machine tool, a fixture support frame 15 and a V-shaped positioning block 13 fixed on the base 14, and a V-shaped positioning groove is processed on the upper surface of the V-shaped positioning block 13. A pressing plate 11 for pressing the workpiece 12 is also provided above the V-shaped positioning groove, and a clamp body that can be adjusted 360° in a vertical plane is provided on the clamp support frame 15 , and the clamp body is used to clamp the end of the workpiece 12 to be positioned. .

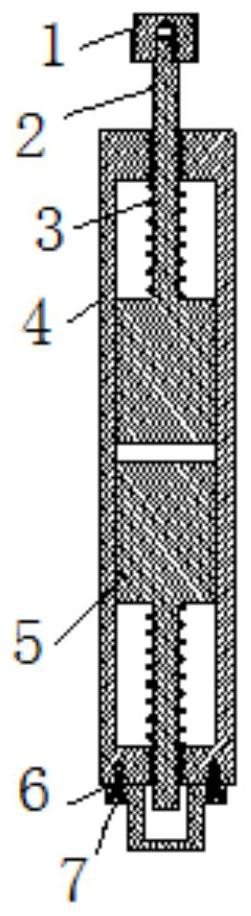

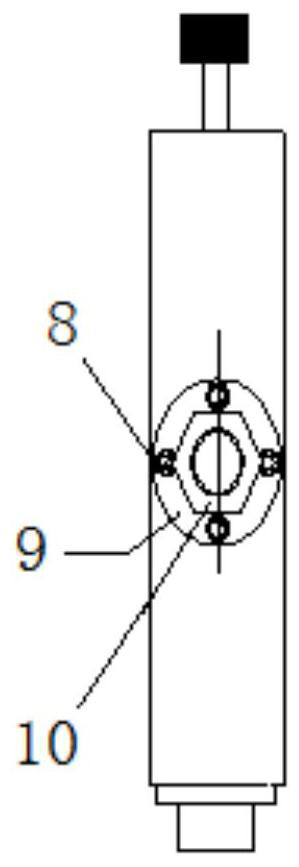

[0040] see again figure 2 and image 3 As shown, the clip body includes a guide box 4 with an open side and a linear guide cavity, and an active positioning block 2 and a driven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com