Boring bar rotating assembly of horizontal piercing boring mill

A technology of rotating assembly and boring bar, applied in parts of boring machine/drilling machine, metal processing equipment, drilling/drilling equipment, etc. To achieve the effect of stable quality of processed products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

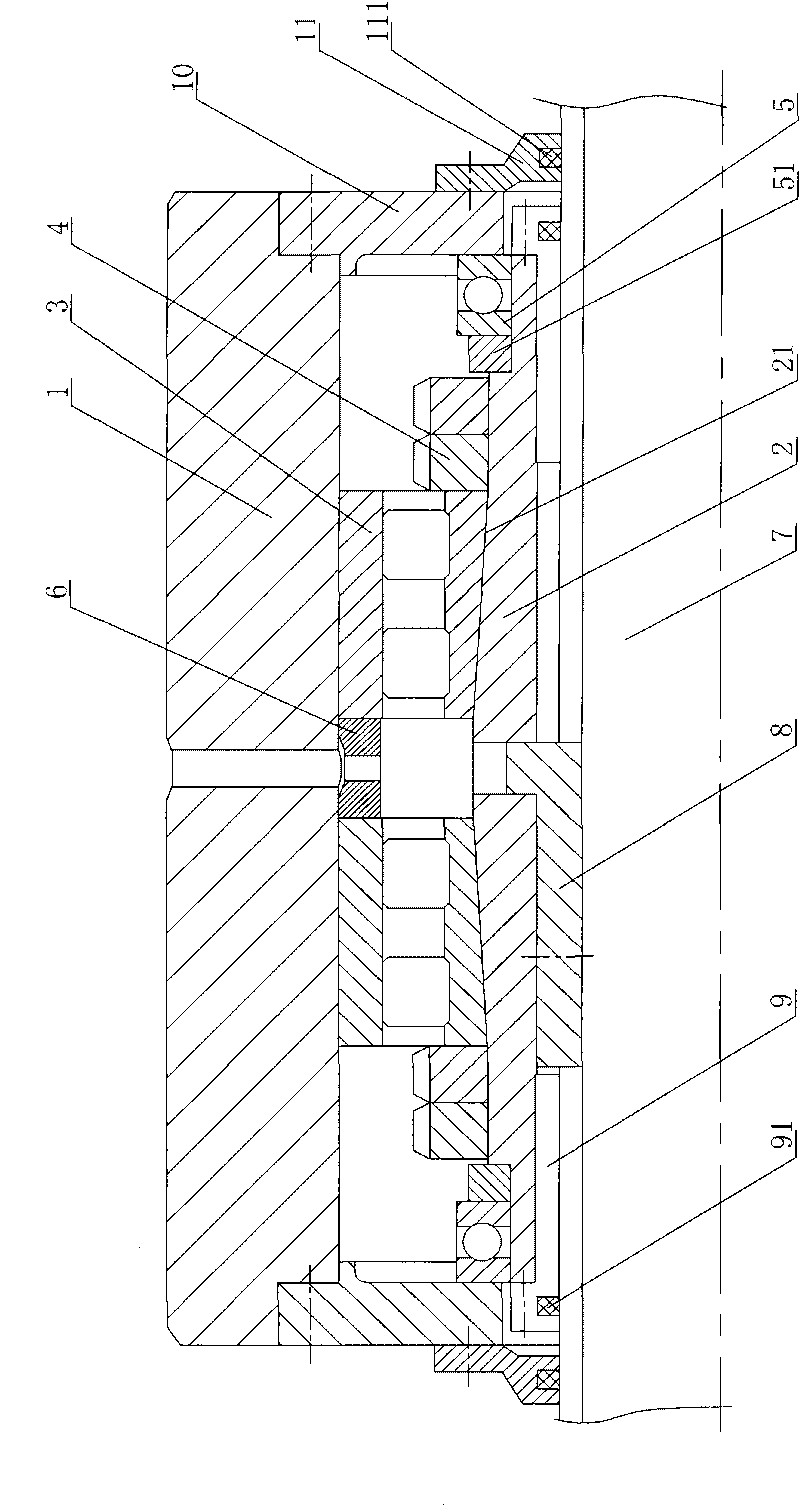

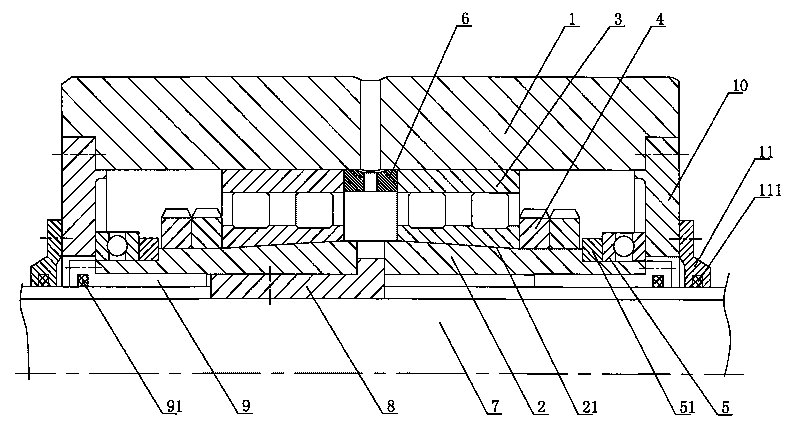

[0014] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0015] figure 1 Shown is the rotating assembly of the boring bar of the horizontal core-through boring machine of the present invention, including the boring bar 7, the bearing sleeve 1, the bearing body 2 and the bearing arranged between the bearing sleeve 1 and the bearing body 2, the middle part of the bearing body 2 There are two sections of taper 21 with taper, the taper 21 is set with a cylindrical roller bearing 3 with a tapered inner ring, the outer side of the cylindrical roller bearing 3 is provided with a double round nut 4, the bearing body 2 Thrust ball bearings 5 are sleeved at both ends respectively. A spacer ring 6 is arranged between the cylindrical roller bearings 3 . The boring bar 7 is provided with a keyway, and the guide sliding key 8 placed in the keyway is fixed with the bearing body 2 by bolts. Both ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com