Grinding method for runway part

A grinding method and technology for parts, applied in the field of mechanical processing, can solve the problems of inability to meet the requirements of surface roughness and flatness, and achieve the effect of improving the quality of grinding and stable quality of processed products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

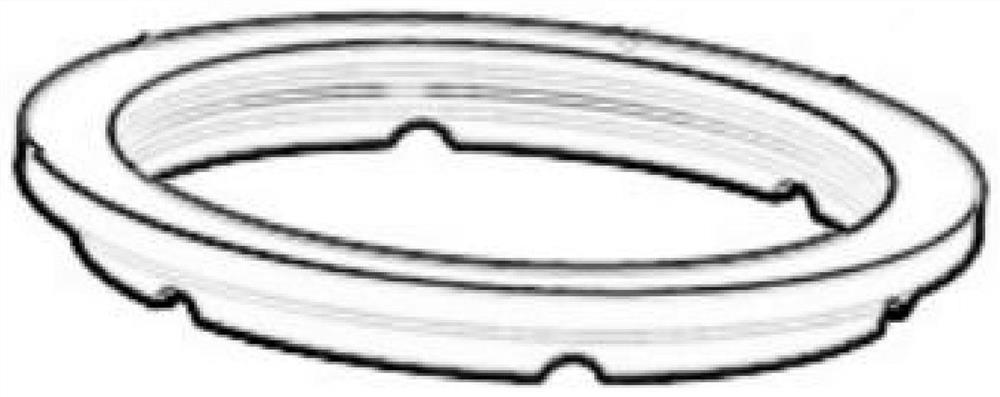

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

[0024] A grinding method for runway parts, comprising the following steps:

[0025] S1, Parts preparation: Prepare the raceway parts, and use a surface grinder to perform initial grinding on the end faces of the raceway parts to be ground, so that the parallelism between the upper and lower end faces of the raceway parts is 0.01, and the remaining grinding allowance is 0.03-0.04;

[0026] S2, grinding platform preparation: the grinding platform is a cast iron sand pressing platform of HT200-300, the platform size is 300mm×300mm, and the hardness is HB170-240; the grinding platform has been subjected to high temperature annealing and aging treatment;

[0027] S3, configure abrasives: configure high, medium, and low abrasives made of gasoline and abrasive sand, the abrasive sand particle size of the high abrasive agent is 1.5, the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com