A climbing-type clamping device for a top heading pipe bender and its application method

A technology of clamping device and pipe bending machine, which is applied in the direction of feeding device, positioning device, storage device, etc., can solve problems affecting production, etc., and achieve the effects of high processing efficiency, strong power output, and wide processing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

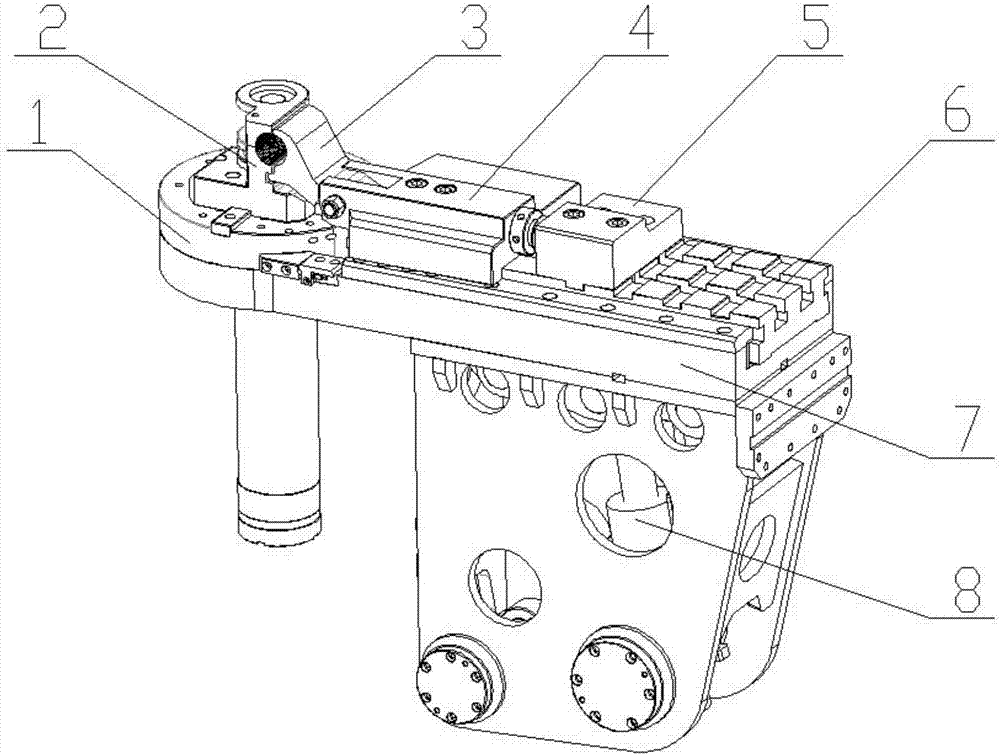

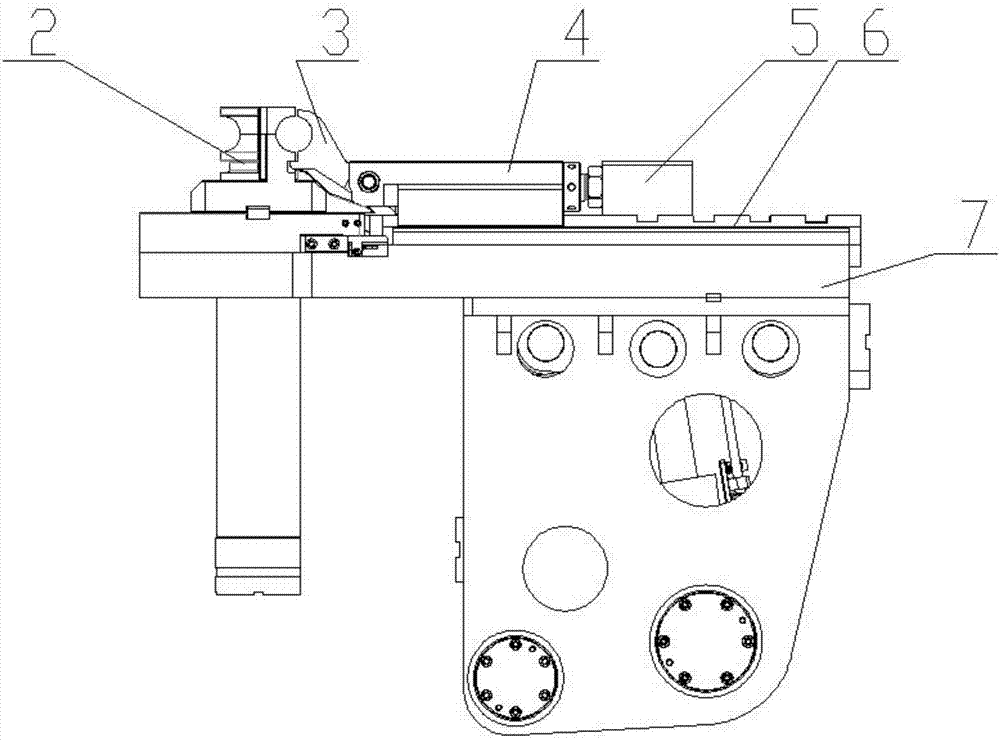

[0047] Such as figure 1 , figure 2 and image 3 As shown, a climbing type clamping device for a top heading pipe bender includes a main mold base 1, a main mold 2, a clamping mold 3, a clamping mold base 4, a slider 6, a slider base 7 and a slider drive 8; The main mold base 1 is set on the frame of the top heading pipe bending machine through the main mold shaft. The main mold base 1 can rotate around the main mold axis. The rotation is the driving force for the bending process of the pipe fittings; top; the upper surface of the clamping base 4 is lower than the lowest point of the main die mouth 21 on the main mold 2, so that the installation and disassembly of the pipe fittings will not be interfered by the clamping base 4;

[0048]The slider base 7 is fixedly connected with the main mold base 1, the upper surface of the slider base 7 is provided with a slide rail, and the slider 6 is arranged on the slide rail; the clamp mold base 4 is fixedly arranged on the slider 6; ...

Embodiment 2

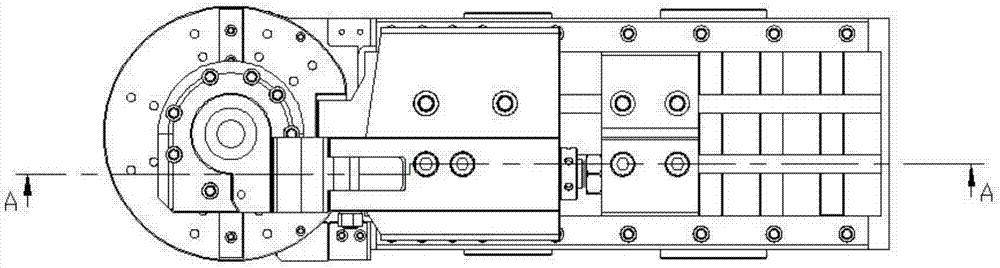

[0055] A climbing-type clamping device for a top heading pipe bender, which is basically the same as that of Embodiment 1, except that a track is provided on the upper surface of the slider 6 close to the main mold 2, and a T-shaped groove is provided on the other side ;Such as Figure 4 or Figure 10 As shown, the mold clamping seat 4 is arranged on the track, and is fixed by the clamping bolt 46, and the clamping mold positioning seat 5 is arranged on the T-shaped groove, and is fixed by the clamping bolt 51; Figure 4 As shown, the clamping mold base 4 is provided with a clamping mold fixing groove 41 at one end close to the main mold 2, the clamping mold 3 is rotatably arranged in the clamping mold fixing groove 41 through a pin shaft, and the other end of the clamping mold base 4 is provided with a clamping mold fine-tuning Rod 42, clamping mold fine-tuning lever 42 one end is threadedly connected with the end face of clamping mold base 4, and the other end contacts with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com