Crosslinking polyolefin microporous membrane and preparation method thereof

A polyolefin microporous membrane, cross-linked technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of poor tolerance to strong alkali and chlorine-oxygen compounds, etc., and achieve outstanding mechanical strength , Improve mechanical strength and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

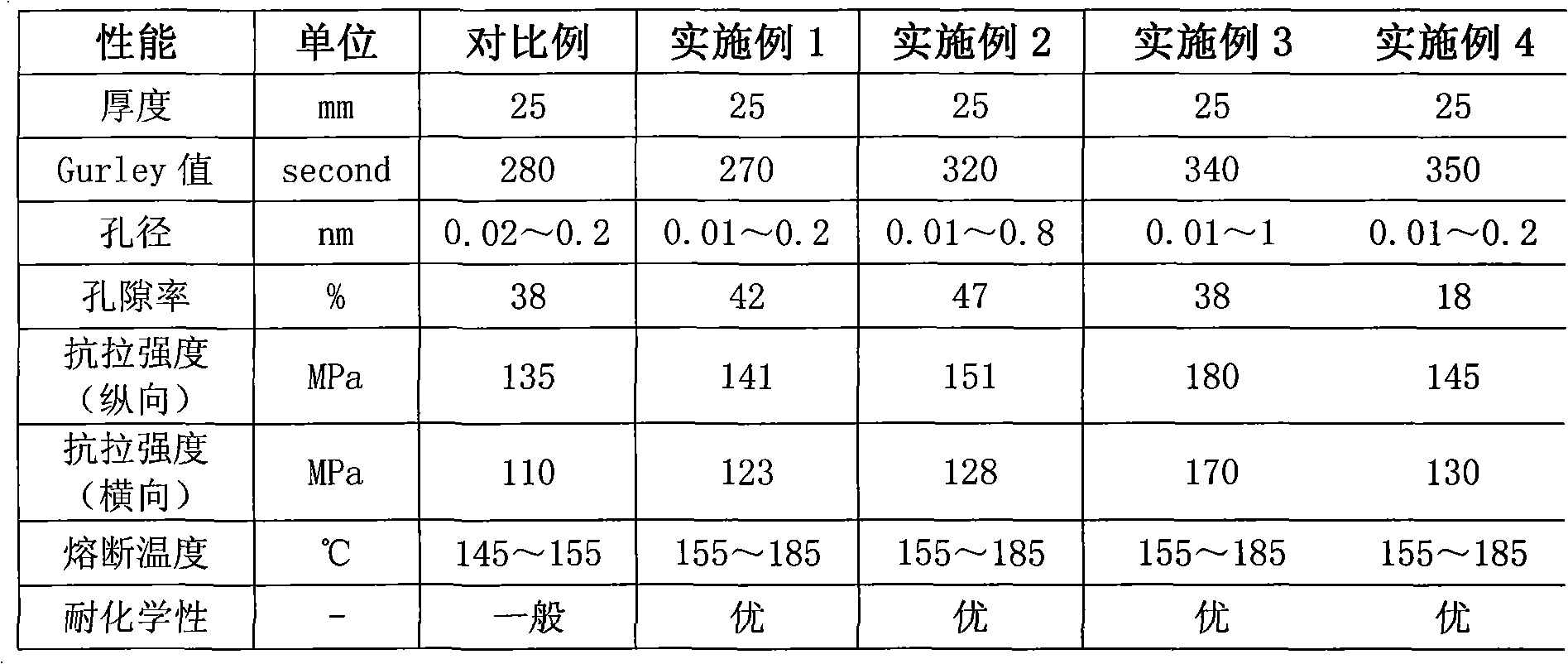

Examples

Embodiment 1

[0051] In embodiment 1, used polyolefin is high-density polyethylene, latent solvent is naphtha, peroxygen compound is peroxygen compound Luperox 101, and silane is trimethoxyvinyl silane, and superfine filler is nanometer calcium carbonate, average The particle size is 0.05 microns. The raw material formula of embodiment 1 is as follows (by weight percentage):

[0052] HDPE 42.9%

[0053] Naphtha 30%

[0054] Peroxide compound Luperox 101 2%

[0055] Trimethoxyvinylsilane 5%

[0056] Antioxidant AO168 0.1%

Embodiment 2

[0058] In Example 2, the polyolefin used is long-chain branched polyethylene, the latent solvent is dioctyl adipate, the peroxide compound is peroxide compound Luperox TBEC, and the silane is trimethoxymethacrylate propyl silane, ultrafine The filler is ultrafine calcium carbonate with an average particle size of 0.1 microns. The raw material formula of embodiment 2 is as follows (by weight percentage):

[0059] Long chain branched polyethylene 35.9%

[0060] Dioctyl Adipate 40%

[0061] Luperox TBEC 1%

[0062] Trimethoxypropyl methacrylate 3%

[0063] Antioxidant AO168 0.1%

Embodiment 3

[0065] In Example 3, the polyolefin used is a combination of high-density polyethylene and ultra-high molecular weight polyethylene, the latent solvent is liquid paraffin, the peroxide compound is peroxide compound Luperox 130, and the silane is triisopropoxysilane. The filler is ultrafine calcium carbonate with an average particle size of 1 micron. The raw material formula of embodiment 3 is as follows (by weight percentage):

[0066] HDPE 14.4%

[0067] UHMWPE 14.4%

[0068] Liquid Paraffin 50%

[0069] Peroxy compound Luperox 130 0.1%

[0070] Triisopropoxysilane 1%

[0071] Antioxidant AO168 0.1%

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com