Infiltration method for treating garbage

A landfill leachate and treatment method technology, which is applied in the field of sewage treatment, can solve problems such as large changes in water quality and quantity, high ammonia nitrogen content, and difficult to treat high-concentration organic wastewater, and achieve high efficiency, low consumption, high degree of automation, and excellent treatment effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

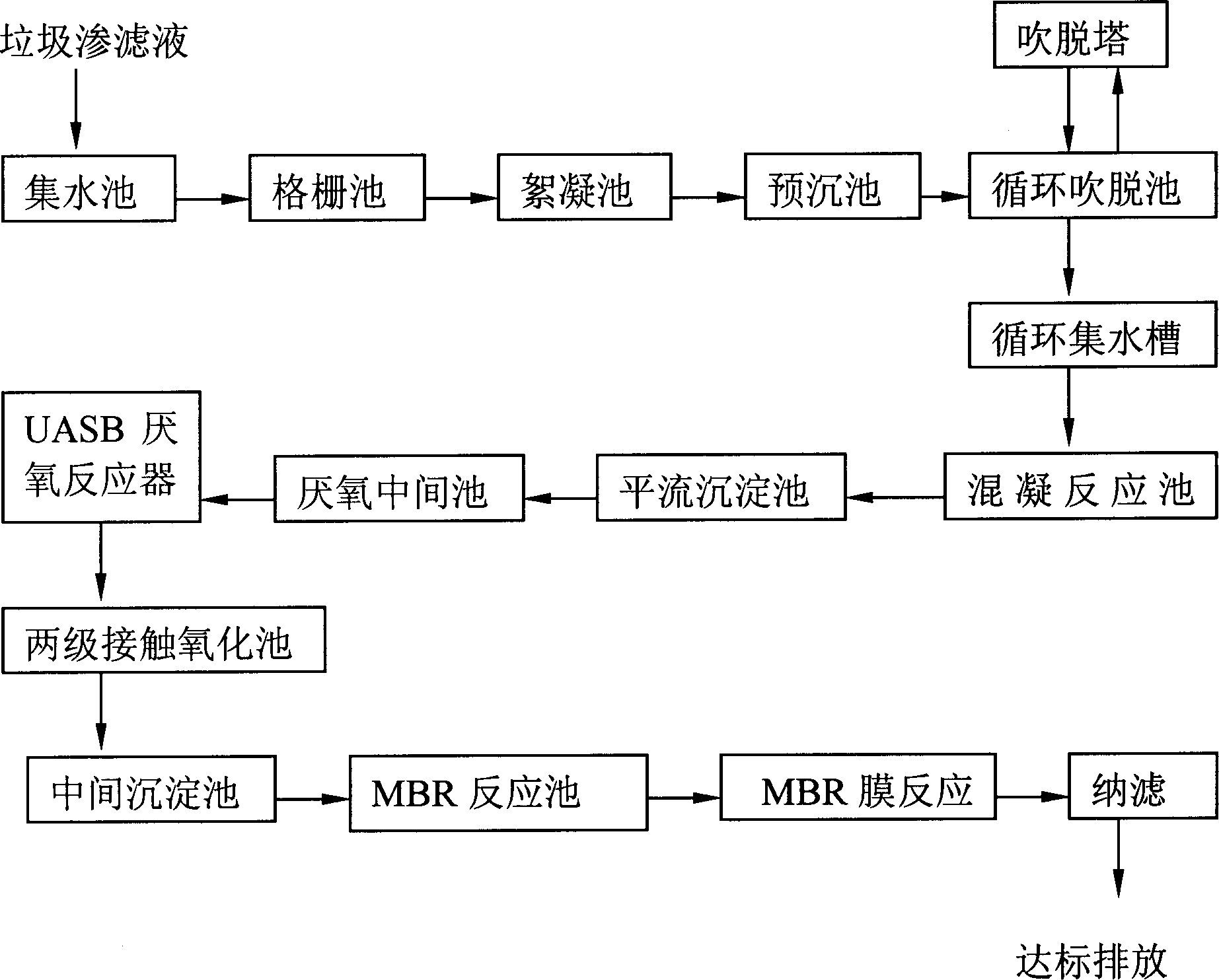

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below.

[0029] The specific embodiment of the present invention is the waste leachate sewage treatment process of the Shenzhen Pinghu waste incineration power plant, and the daily waste treatment capacity of the power plant is 900 tons. Garbage dumps produce a certain amount of leachate sewage, with a daily sewage volume of about 120 tons. This leachate is a kind of high-concentration organic sewage, containing high concentrations of ammonia nitrogen, organic matter and other pollutants. In this embodiment, when landfill leachate enters the system, COD Gr (Chemical oxygen demand) peak value reached 61250mg / L, SS (suspended solids) reached 5000mg / L, and the average value was around 3000mg / L.

[0030] like figure 1 , The landfill leachate is first collected through the sump, and a pump pit is set at the bottom of the sump to regularly pump away the sludge staying at the bottom of the sump.

[0031] The sewage f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com