Method for efficiently recycling valuable element in aluminum ash

A valuable element, aluminum recovery technology, applied in chemical instruments and methods, hydrogen production, alkali metal aluminate/alumina/aluminum hydroxide preparation, etc., can solve problems affecting product quality, chloride and ammonia separation. Complete, chlorine salt is not easy to elute and other problems, to achieve the effect of simple equipment, efficient separation and recycling, and efficient recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

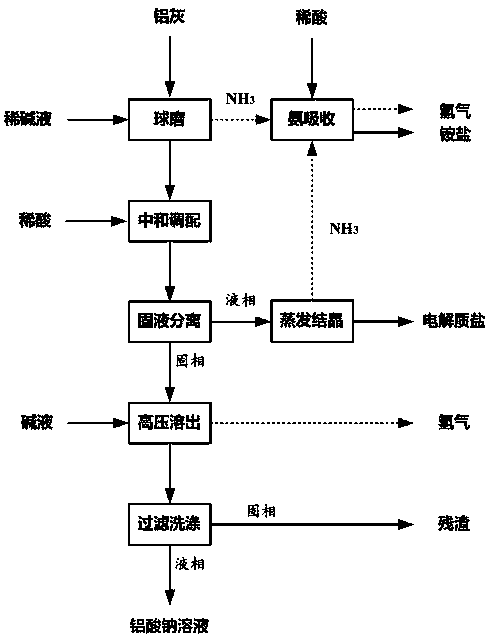

[0033] The method for efficiently recovering valuable elements in aluminum ash of the present invention, the specific process steps are as follows:

[0034] (1) Aluminum ash wet grinding: mix secondary aluminum ash (see Table 1 for specific composition) and water from a company in Luoyang into the ball mill at a liquid-solid ratio of 2, control the speed of the ball mill, and keep the material in the ball mill. The time is 40min, the particle size of the material in the ball mill slurry is d 90 ≤300 mesh, the tail gas generated during the ball milling process is introduced into the spray absorption tower through the negative pressure pipeline;

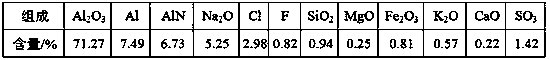

[0035] Table 1 Chemical composition of secondary aluminum ash of a company in Luoyang (dry basis):

[0036]

[0037] (2) Neutralization and preparation: use 15% hydrochloric acid to carry out acid-base preparation on the slurry after ball milling, and control the final pH value of the slurry to 6.5;

[0038] (3) Solid-liquid separ...

Embodiment 2

[0044] The method for efficiently recovering valuable elements in aluminum ash of the present invention, the specific process steps are as follows:

[0045](1) Aluminum ash wet grinding: the secondary aluminum ash (see Table 2 for specific composition) and C Na2O The NaOH solution of =80g / L is mixed into the ball mill according to the ratio of liquid to solid ratio of 1.5, the speed of the ball mill is controlled, the residence time of the material in the ball mill is kept at 20min, and the particle size of the material in the ball mill slurry is d 90 ≤200 mesh, the tail gas generated during the ball milling process is introduced into the spray absorption tower through the negative pressure pipeline;

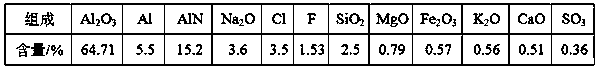

[0046] Table 2 Chemical composition of secondary aluminum ash in a company in Gongyi (dry basis):

[0047]

[0048] (2) Neutralization and preparation: Use 15% hydrochloric acid to carry out acid-base preparation on the slurry after ball milling, and control the final pH va...

Embodiment 3

[0055] The method for efficiently recovering valuable elements in aluminum ash of the present invention, the specific process steps are as follows:

[0056] (1) Aluminum ash wet grinding: the secondary aluminum ash (see Table 3 for specific composition) and C Na2O The NaOH solution of =50g / L is mixed into the ball mill according to the ratio of liquid to solid ratio of 1.2, the speed of the ball mill is controlled, and the residence time of the material in the ball mill is kept at 15min, and the particle size of the material in the ball mill slurry is d 90 ≤200 mesh, the tail gas generated during the ball milling process is introduced into the spray absorption tower through the negative pressure pipeline;

[0057] Table 3 Chemical composition of secondary aluminum ash of an enterprise in Luoyang (dry basis):

[0058]

[0059] (2) Neutralization and preparation: use 15% hydrochloric acid to carry out acid-base preparation on the slurry after ball milling, and control the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com