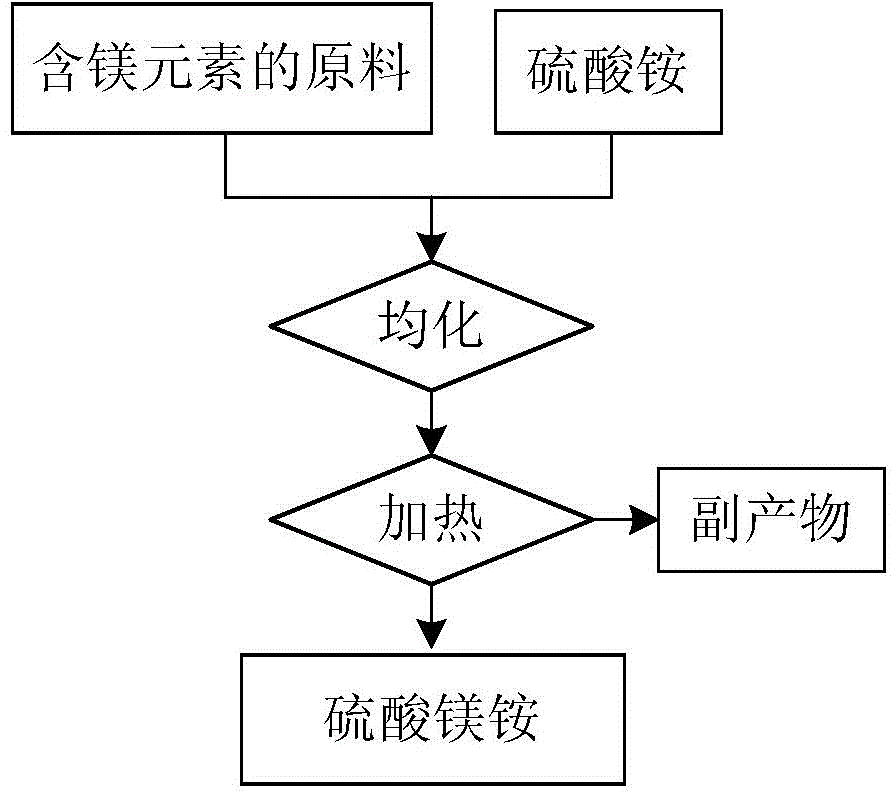

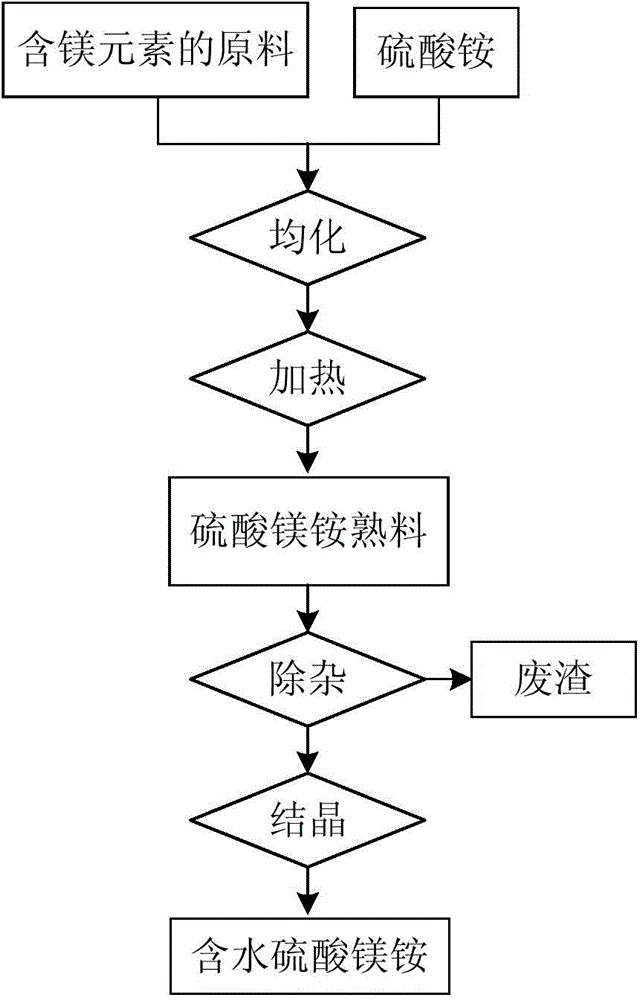

Ammonium magnesium sulfate preparation method

A technology of magnesium ammonium sulfate and ammonium sulfate, which is applied in the preparation of magnesium sulfate and ammonium salt, ammonium carbonate/acid carbonate, etc., can solve the problems of high theoretical energy consumption and complicated process, and achieve increased homogenization. degree, improve quality, increase the effect of the effect of the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] A preparation method for ammonium magnesium sulfate, comprising the steps of:

[0062] (1) Take 20kg of active magnesium oxide (purity: 98.5wt%, water content less than 1.0wt%) and 134kg ammonium sulfate (purity: 99.0wt%) into the V-type mixer, homogenize for 2 hours, and obtain a homogeneous raw material mixture ; In the mixture, the ratio of the amount of magnesium element and sulfate radical is 1:2.04;

[0063] (2) Heat the raw material mixture at a rate of 0.5°C / min to 240°C for 18 hours to obtain ammonium magnesium sulfate;

[0064] (3) Collect the gas produced by the reaction and pass it into water to obtain the by-product ammonia water.

Embodiment 2

[0066] A preparation method for ammonium magnesium sulfate, comprising the steps of:

[0067] (1) Lightly burn magnesite powder at 750°C for 18 hours to obtain lightly burned magnesium oxide powder (magnesia content is 96.2%);

[0068] (2) Take 200g of light-burned magnesia and 1200g of ammonium sulfate obtained in step (1), add them into a dry-process ball mill, and homogenize for 1 hour by ball milling to obtain a homogeneous raw material mixture; in the mixture, the amount of magnesium element and sulfate radical The ratio is 1:1.82;

[0069] (3) Raise the temperature of the raw material mixture to 300°C at a rate of 2°C / min, then raise the temperature to 500°C at 1°C / min and keep it warm for 1 hour to obtain ammonium magnesium sulfate clinker;

[0070] (4) Slowly add the anhydrous ammonium magnesium sulfate clinker to 2000mL deionized water, keep stirring, and control the temperature of the slurry to 80°C;

[0071] (5) Adjust the pH value of the slurry to 6.1-6.3, and st...

Embodiment 3

[0074] A preparation method for ammonium magnesium sulfate, comprising the steps of:

[0075] (1) Take 40g of brucite powder (with a magnesium hydroxide content of 95.7%) and 300g of ammonium sulfate, place them in a mortar and grind for homogenization for 2 hours to obtain a homogeneous raw material mixture; in the mixture, the amount of magnesium and sulfate The ratio is 1:2.35;

[0076] (2) The mixture obtained in step (1) was heated up to 150°C at a rate of 24°C / min, and then heated to 590°C at a rate of 0.2°C / min for 10 minutes to obtain ammonium magnesium sulfate clinker;

[0077] (3) Slowly add the anhydrous ammonium magnesium sulfate clinker into 750mL deionized water, keep stirring, and control the temperature of the slurry to 70°C;

[0078] (4) Adjust the pH value of the slurry to 7.0-7.2, and stir for 0.5h;

[0079] (5) Centrifuge the slurry obtained in step (4) to obtain a solution, cool the solution to 50°C, evaporate, and stand for crystallization, and the obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com