Process for scrubbing ammonia from acid gases comprising ammonia and hydrogen sulfide

A sour gas and hydrogen sulfide technology, applied in chemical instruments and methods, separation methods, gas fuels, etc., can solve expensive and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

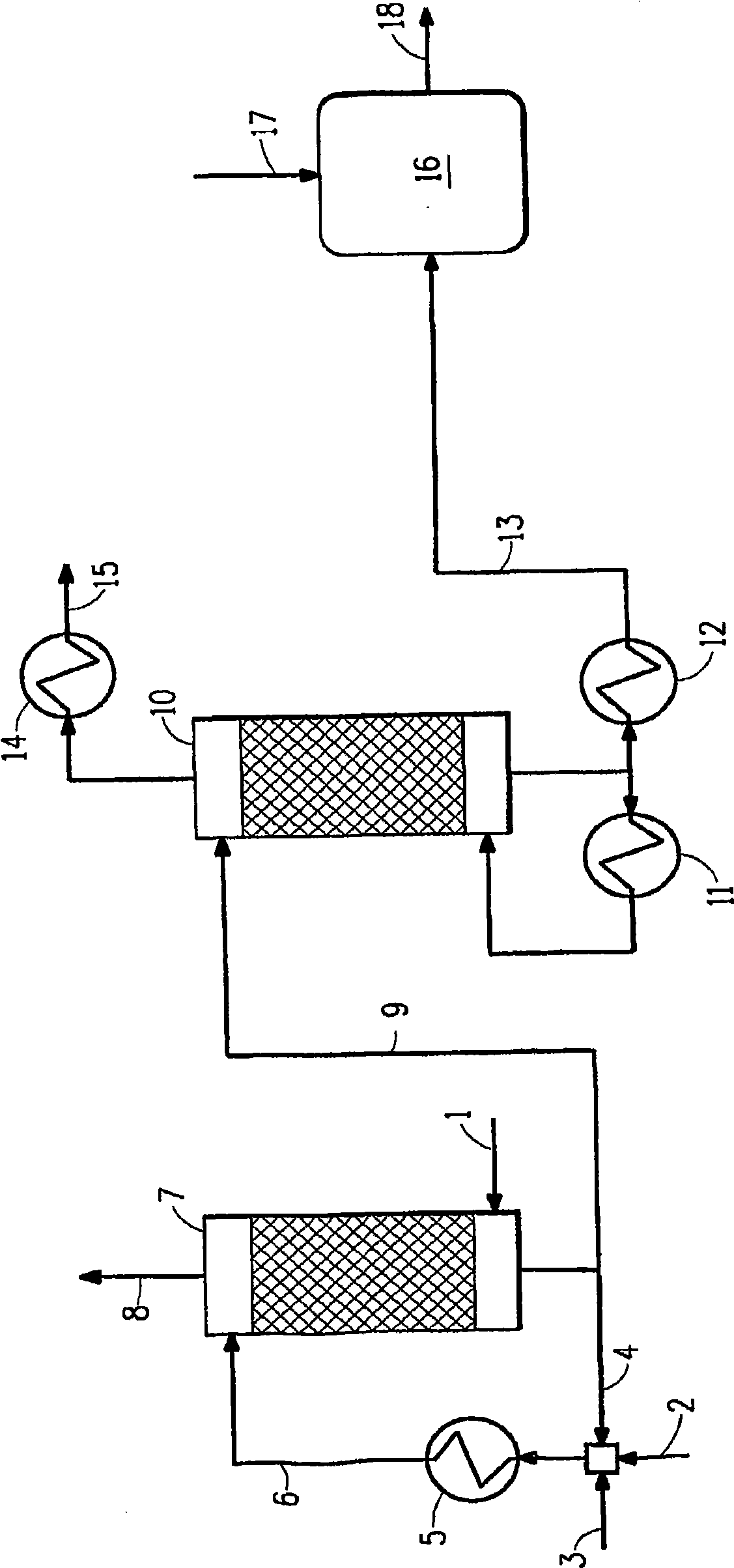

[0067] conduct figure 1 Computer modeling simulation of the method described in . A 143.3 lb mol / h (65 kgmol / h) sour water stripper containing 38.6 vol% ammonia (equivalent to 0.28 mass fraction) was used using recycled acid effluent (weak acid, including 5 wt% sulfuric acid) and fresh acid (98 wt% sulfuric acid) Scrubbing ammonia in the gas. Stream profiles and concentrations throughout the simulation for this example are shown in Table 1 below.

Embodiment 2

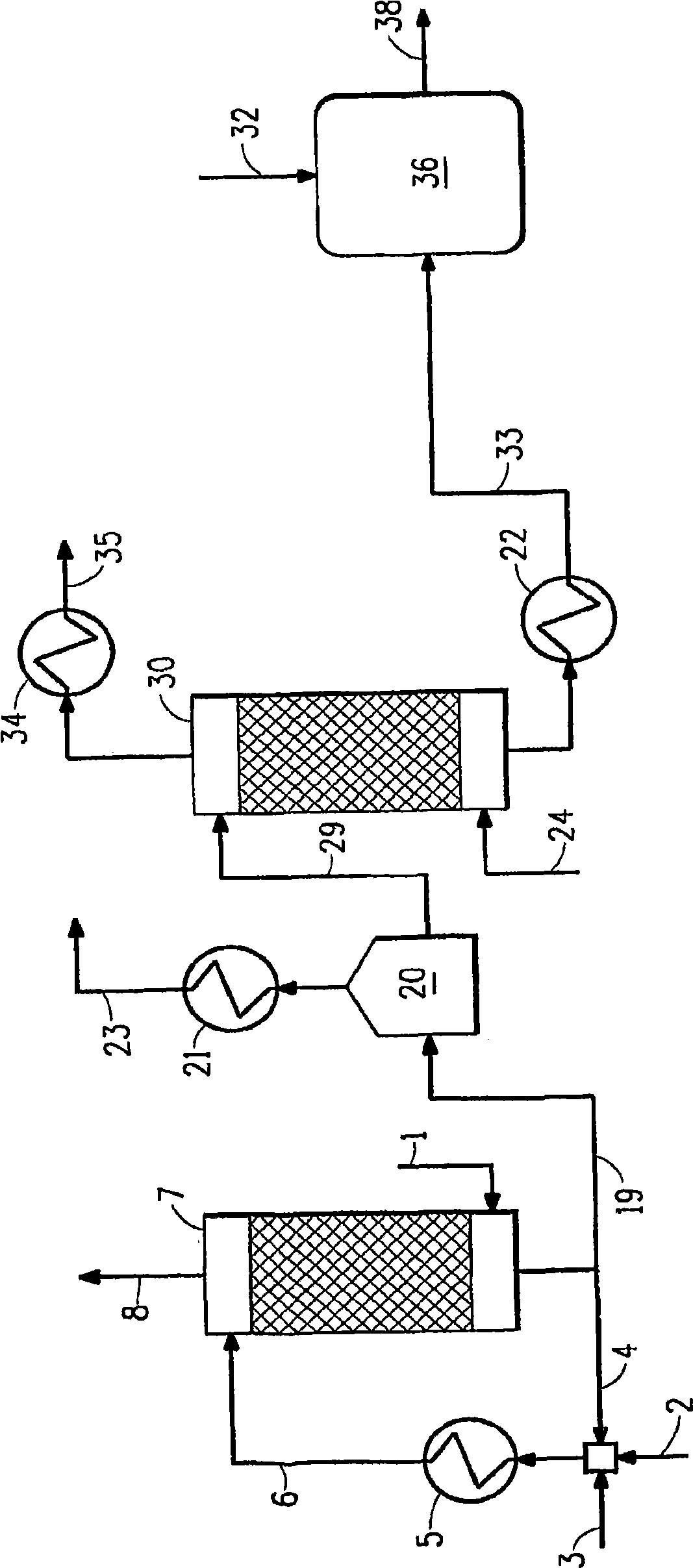

[0069] conduct figure 2 Computer modeling simulation of the method described in . Stripped from 143.3 lb mol / h (65 kg mol / h) of acidic water including 38.6 vol% ammonia (equivalent to 0.28 mass fraction) using recycled acid effluent (weak acid, including 5 wt% sulfuric acid) and fresh acid (98 wt% sulfuric acid) Ammonia scrubbing in tower gas. Flow profiles and concentrations throughout the simulation for this example are shown in Table 2 below.

Embodiment 3

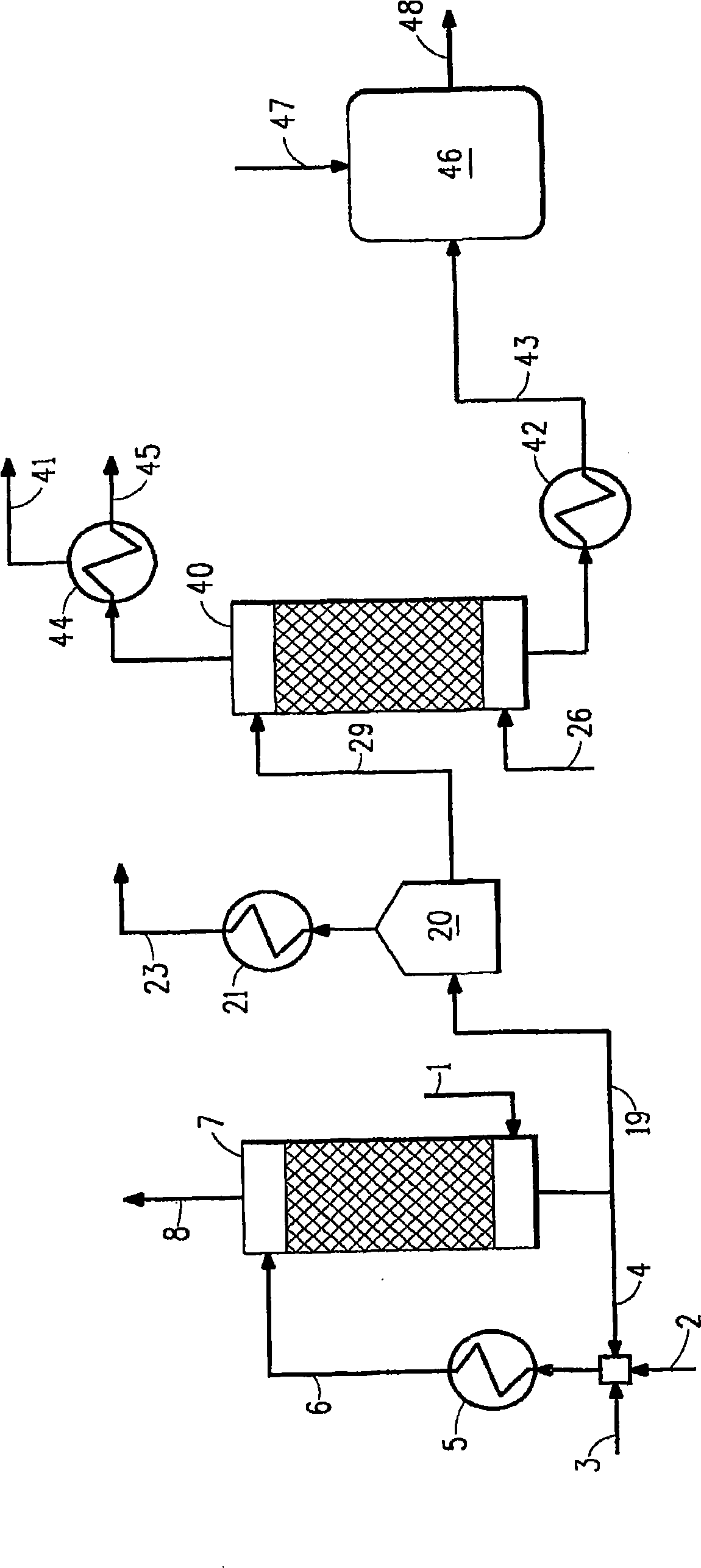

[0071] conduct image 3 Computer modeling simulation of the method described in . Stripped from 143.3 lb mol / h (65 kg mol / h) of acidic water including 38.6 vol% ammonia (equivalent to 0.28 mass fraction) using recycled acid effluent (weak acid, including 5 wt% sulfuric acid) and fresh acid (98 wt% sulfuric acid) Ammonia scrubbing in tower gas. Flow profiles and concentrations throughout the simulation for this example are shown in Table 3 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com