Surface coating method of ammonium salts

A technology of surface coating and ammonium salt, which is applied in the fields of ammonium salt preparation, special surface, and device for coating liquid on the surface, etc. It can solve the problems of high processing cost and unsuitable implementation, and achieve the effect of uniform surface coating layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

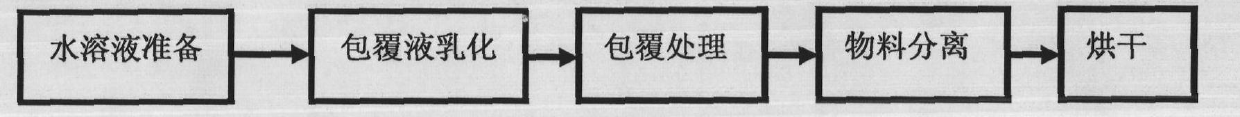

Method used

Image

Examples

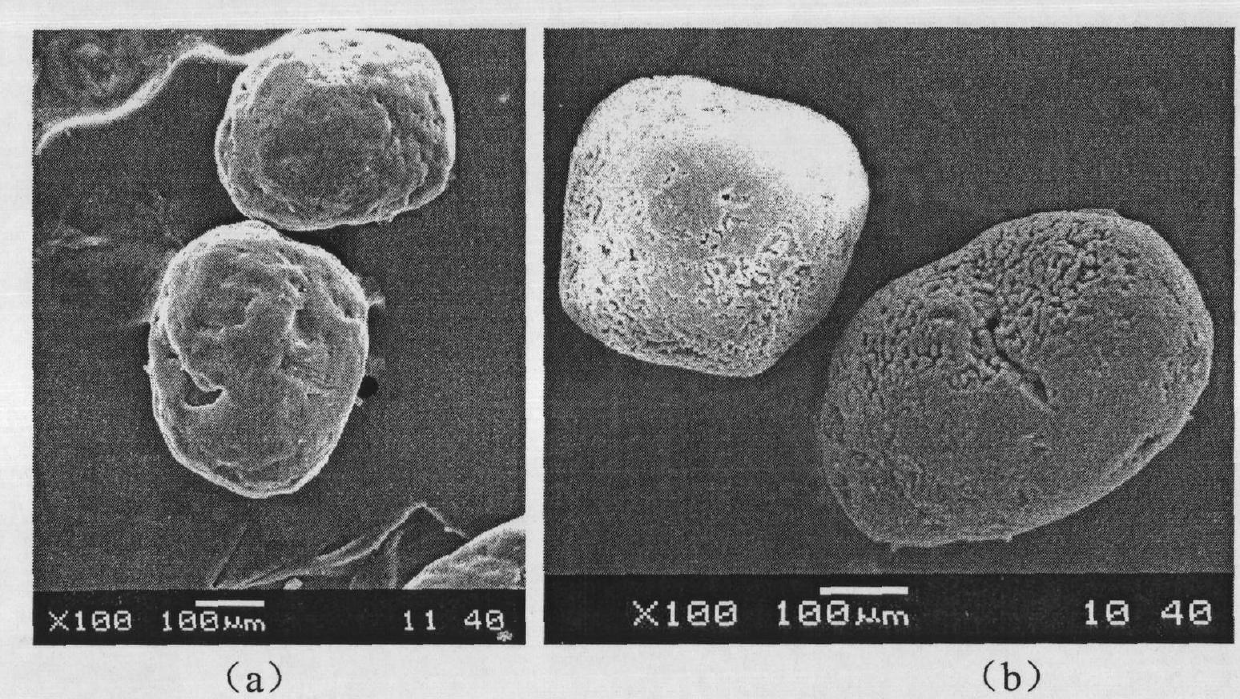

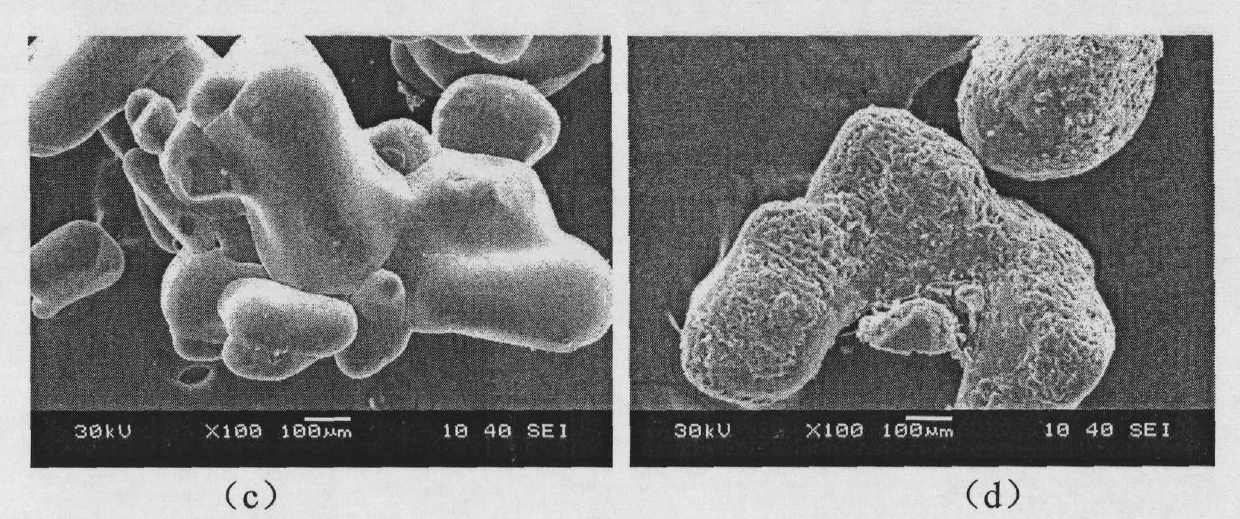

Embodiment 1

[0038] At room temperature, weigh 5g of formaldehyde solution with a content of 49%, add it to a 50ml round bottom flask, add quantitative solid potassium silicate therein, the ratio of potassium silicate to formaldehyde is 2:3 according to the ratio of the amount of substance Calculate (based on the content of potassium oxide therein), stir for 10-20 minutes until all solids are dissolved, and then prepare for emulsification of the coating solution. Add 100g of petroleum ether (boiling point 60-90 degrees) into the emulsifier, then add 0.5g of Span 80 emulsifier, start the stirring of the emulsifier and add the pre-prepared potassium silicate formaldehyde mixed solution evenly within 5 minutes In the organic phase, after the emulsification treatment was continued for 20 minutes, the material was in a translucent state, and the emulsification of the coating liquid was completed. After the emulsification is completed, immediately add 100 g of ammonium perchlorate spherical part...

Embodiment 2-11

[0040] Ammonium perchlorate was coated with the same process as in Example 1, and different dispersion media were used for comparison. The comparison results of treatment conditions and coating effects are shown in the following table.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com