Process for recycling ammonia gas for vanadium preparation to prepare ammonium and recycling wastewater

A wastewater circulation and ammonia gas technology, applied in the direction of process efficiency improvement, vanadium oxide, vanadium compounds, etc., can solve the problems of ammonia gas discharge, complex vanadium extraction process procedures, environmental pollution of rivers and lakes, etc., and achieve the goal of ensuring zero discharge of wastewater Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described through exemplary embodiments below, but these examples do not limit the scope of the present invention, and all materials based on the technology realized by the above content of the present invention all belong to the protection scope of the present invention.

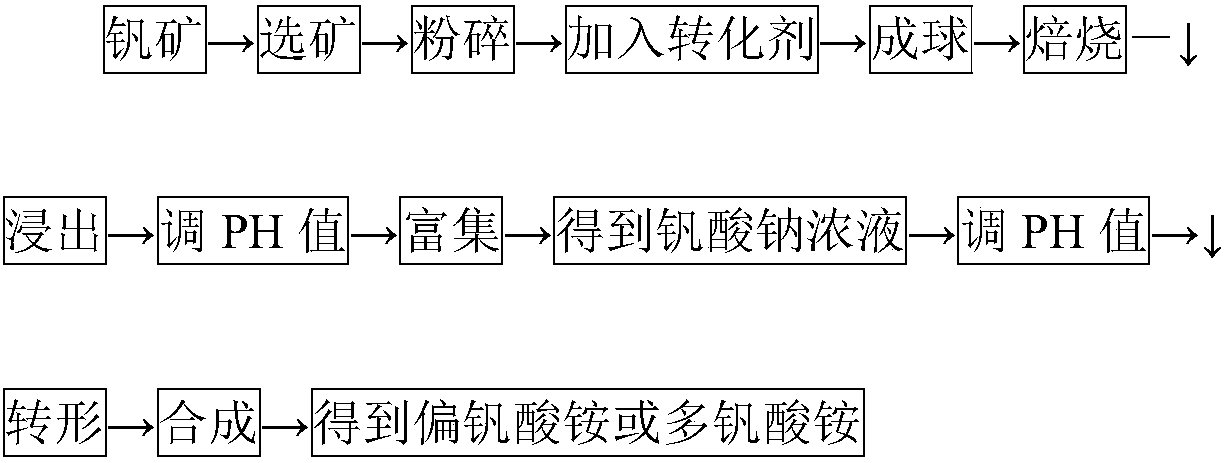

[0028] 1. Starting from mining and smelting, the "one-step method" can be made into ammonium metavanadate (NH 4 VO 3 ) and ammonium polyvanadate (NH 4 )2V 6 o 16

[0029] The crude vanadium ore is leached to obtain sodium vanadate concentrate (according to different processes, different crude vanadium content, different content is prepared) to make ammonium metavanadate (NH 4 VO 3 ) and ammonium polyvanadate (NH 4 )2V 6 o 16 . The process flow is generally:

[0030]

[0031] 1. Vanadium ore. Vanadium (V) containing vanadium slag, vanadium mud or vanadium containing coal gangue.

[0032] 2. Mineral dressing. Choose to remove other impurities other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com