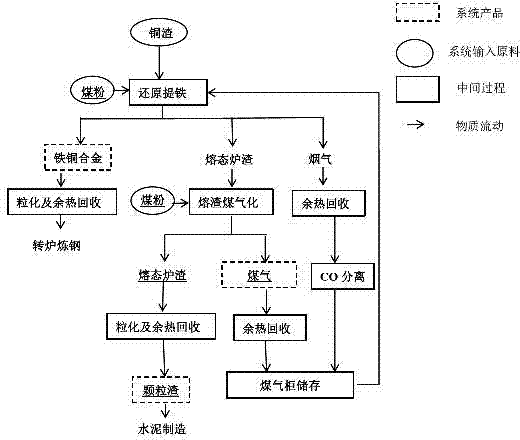

System and method for recovering iron and waste heat from molten copper residues respectively through step-by-step reduction and coal gasification

A technology for coal gasification and iron recovery, applied in the fields of resources and environment, can solve the problems of low iron recovery rate, difficulty in recovering waste heat from copper slag slag, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

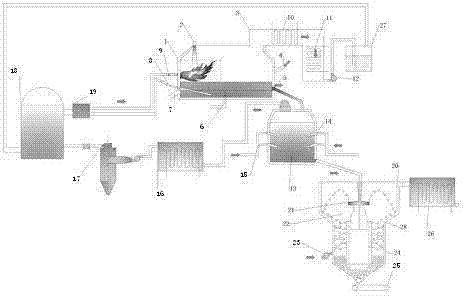

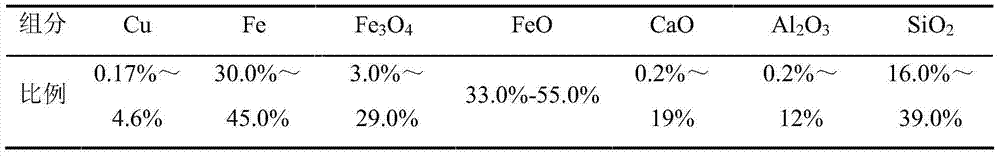

Embodiment 1

[0101] A system for step-by-step reduction and recovery of iron from molten copper slag and recovery of waste heat from coal gasification such as figure 2 As shown, it includes reduction iron extraction furnace 1, coal gasification furnace 13, granulation and waste heat recovery device 22, flue gas heat exchanger 10, 11, gas separation and dust removal device 27, waste heat boiler 16, 24, cyclone dust collector 17, gas Cabinet 18, transportation device 25, in which the gas cabinet 18 is connected to the reduction and iron extraction furnace 1, and the upper end of the reduction and iron extraction furnace 1 is connected to the gas separation and dust removal device 27 through the flue gas heat exchanger 10, 11, and the upper part of the separation and dust removal device 27 is provided with a pipe connection The gas cabinet 18, the slag outlet of the iron reduction furnace 1 is connected to the coal gasification furnace 13, the coal gasification furnace 13 is connected to one ...

Embodiment 2

[0116] The system for step-by-step reduction and recovery of iron and copper from molten copper slag and coal gasification for recovery of waste heat is the same as that of Embodiment 1, the difference is that: the granulation and waste heat recovery device does not have a fan 23 and a waste heat boiler 26, and its annular metal baffle has 7 stages , the length of the baffles is 0.4m, the spacing is 0.4m, and the angle with the horizontal plane is 10°; cold water is passed into the metal water wall for heat exchange;

[0117] Using the above-mentioned device to recover iron and copper step by step from molten copper slag and coal gasification to recover waste heat, the specific steps are as follows:

[0118] (1) Step-by-step reduction for iron extraction and gas recovery:

[0119]The molten copper slag at 1200-1300°C discharged from the copper smelting furnace flows into the iron reduction furnace, and the CO in the gas tank is burned through the gas burner. When the temperatu...

Embodiment 3

[0128] The system for step-by-step reduction and recovery of iron and copper from molten copper slag and coal gasification for recovery of waste heat is the same as in Example 1, except that the granulation and waste heat recovery device does not have a fan 23 and a waste heat boiler 26, and its annular metal baffle plate, 7 stage, the length of the baffles is 0.8m, the spacing is 0.6m, and the angle with the horizontal plane is 30°; cold water is passed through the metal water-cooled wall for heat exchange.

[0129] Using the above-mentioned device to recover iron and copper step by step from molten copper slag and coal gasification to recover waste heat, the specific steps are as follows:

[0130] (1) Step-by-step reduction for iron extraction and gas recovery:

[0131] The molten copper slag at 1200-1300°C discharged from the copper smelting furnace flows into the iron reduction furnace, and the CO in the gas tank is burned through the gas burner. When the temperature of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com