Process for producing active carbon by cyclic utilization of high temperature flue gas

A technology for producing activated carbon and high-temperature flue gas, applied in inorganic chemistry, non-metallic elements, carbon compounds, etc., can solve problems such as environmental pollution and resource waste, and achieve the effect of reducing production costs, avoiding pollution, and avoiding energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

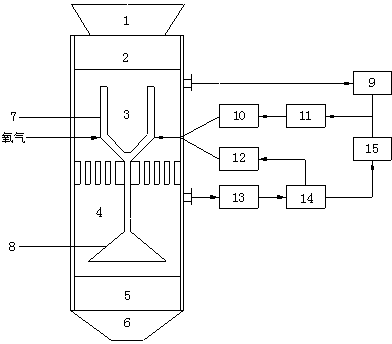

[0027] Implement a kind of technique that recycles high-temperature flue gas to produce gac provided by the present invention, and its described process is as follows:

[0028] First of all, anthracite or bituminous coal is passed through the extrusion molding equipment to form the coal material, and the feeding equipment is fed into the drying chamber 2 through the inlet 1 on the top of the carbonization activation furnace, and the forming material is passed through the carbonization activation furnace. The hot air is used for drying, the drying temperature is 100°C-120°C, the drying time is 30-60 minutes, and it descends slowly.

[0029] Secondly, a carbonization chamber 3 and a pure oxygen burner 7 with a "Y" structure are provided in the middle of the carbonization activation furnace. 4 、H 2 The mixed gas and oxygen with CO are passed into the pure oxygen burner 7 of "Y" structure according to the volume ratio of 1~2:1 for combustion. Carry out carbonization reaction at ...

specific Embodiment approach 2

[0035] The industrial analysis of the molding material used in the present invention is as follows:

[0036] Moisture Ash Volatile matter Fixed carbon M ad A ad V ad FC ad 2.44 3.83 9.62 84.11

[0037] After the above-mentioned molding material is transported to the feed port 1 on the top of the furnace by the conveying device, it slowly descends along the product channel to the drying chamber 2 by gravity, and the molding material is dried at a controlled temperature of 100~120°C. After drying, the molding The material goes down to the carbonization chamber 3, and the pure oxygen burner 7 in the carbonization chamber 3 passes into the high-temperature mixed gas and oxygen in the gas cabinet 10, and is ignited by the ignition device, and the high-temperature mixed gas is burned in the pure oxygen burner 7, and the adjustment The flow of high-temperature water vapor and carbon dioxide enters the lower "horn" type gas distributo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com